1 / 4Inch TP321 / 321H Stainless Steel Seamless Hydraulic Tube For Food Industry

SSBA51

Price: From $9000-12000USD/TON

Material: 321,321H, 1.4541;

Get Quote

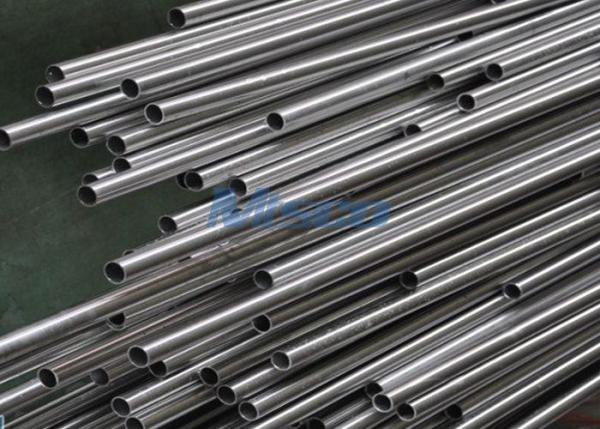

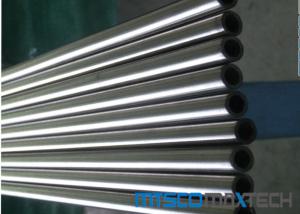

TP321 / 321H Stainless Steel Seamless Hydraulic Tube With Bright Annealed Surface

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement .

Stainless steel seamless bright annealed tube’s final surface is polished and bright annealed . And the polished grade is includes 180 # , 320 # , 400 # , 600 # , 800 # . According to standard very strictly , tubes which produced by us always have correct OD and WT tolerance . At fluid industry , bright annealed hydraulic tubing has its own important position . Their useful life is higher than other tubing .

| Grade | 304 , 304L , 304H , 310S , 316 , 316L , 316Ti , 321 , 321H , 347 , 347H , etc |

| Standard | ASTM A270 ; ASTM A269 ; ASTM A312 ;ASTM A249 ; EN10216-5 , ect . |

| Size | OD : 3.18 - 101.6mm |

| WT : 0.5 - 20mm | |

| Length : 1m to 12m or as per customers' requirement | |

| Advantage | Superior surface finish ,better mechanical property; more precise dimension; perfect inspection method and inspection equipment |

Chemical Composition:

| C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti | |

| TP304/1.4301 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/1.4541 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/1.4449 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 | |

| TP347H/1.4912 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/1.4833 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/1.4845 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | 0.75 |

| Basic Information | Material Grade | TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , S31803 , S32750 , S32205 etc |

| Outer Diameter | 3.18-101.6mm | |

| Wall Thickness | 0.5-20mm | |

| Length | Normally fixed length 6m , can as per customer’s requirement | |

| Standard | ASTM A213 ; ASTM A269 ; ASTM A312 ; ASTM A789 ; ASTM A790 ect . | |

| Process Method | Cold Drawn or Cold Rolled | |

| Industry & Advantage | Application | a) For fluid & gas transport |

| b) Structure & machining | ||

| c) Petrochemical | ||

| d) Environmental protection | ||

| e) Electricity | ||

| f) Instrument industry etc | ||

| Advantages | a) Superior surface finish | |

| b) Better mechanical property | ||

| c) More precise dimension | ||

| d) Perfect inspection method and inspection equipment |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM B622 Nickel Alloy Tube Alloy G-35 Seamless Tube For Chemical Environments

Features: Alloy G-35 / UNS N06035 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydro......

ASTM B829 Inc 625 / Inc 617 Nickel Alloy Seamless Tube

Alloy 625 Metallurgical structure: 625 is face-centered cubic lattice structure. Dissolve out the carbon granule and instability quaternary phase, then change it to stability Ni3 (Nb,Ti) trimetric lattice around 650℃ after a long time heat preservation. nickel-chromium content will strength the me......Structure and machining pipe Casing Tube

High-Tech This is the type of drawing used for the highest quality output. The outside and insida diameters of the mother tube are worked at the same time. A floating plug made of high grade tool steel with a polished surface is located inside the mother tube. As the tube is drawn through the di......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語