ASTM A269 TP347/347H Cold Rolled Stainless Steel Polished Tube

SSBA52

Price: From $12000-15600USD/TON

Material: 347/347H,1.4550,1.4961;

Get Quote

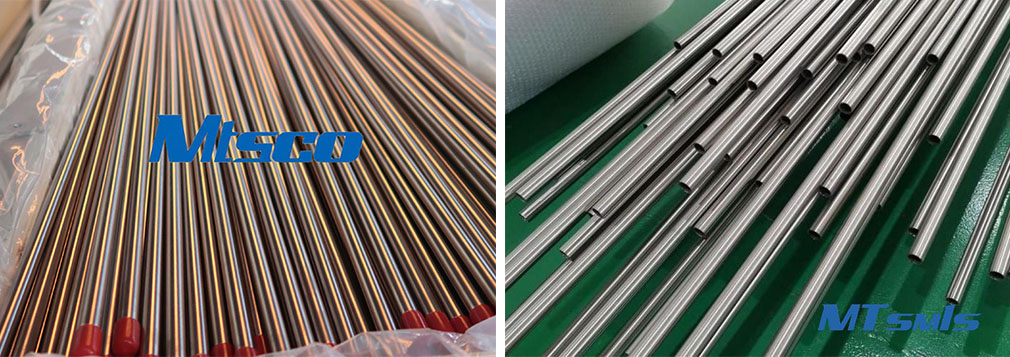

ASTM A269 TP347/347H Cold Rolled Stainless Steel Polished Tube

Quality of MTSCO Stainless Steel Polished Tube:

Quality Assurance for Raw Materials

| Grade | Standard | Outside Diameter | 3.18mm-38mm |

| TP304 TP304L TP316 TP316L TP317L TP321 TP321H TP347 TP347H TP904L | ASTM-A269 ASTM-A213 ASTM-B268 ASTM-B444 ASTM-B167/163 ASTM-B622 ASTM-B423 ...... | Wall Thickness | 0.5mm-3mm |

| Length | ≤30m | ||

| Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

Chemical Composition of TP347 Polished Tube:

| Material | Chemical Composition % Max ASTM A269 | |||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | Nb | Ti | |

| TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | - | - | - |

| TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | - | - | - |

| TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | - | - |

| TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | - | - |

| TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | - | - | 5C -0.70 |

| TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | - | 10C -1.10 | - |

What is the Features of TP347 Polished Tube?

TP347 stainless steel tube is typically made from 18-8 stainless steel with alloying elements such as Niobium and Titanium. These alloying elements provide improved resistance to heat and corrosion, especially in high temperature environments. TP347 tubes are similar to TP321 tubes, but have better resistance to weld intergranular corrosion. As a result, they are widely used in high-temperature, highly corrosive environments, such as the chemical, oil and gas industries. TP347 stainless steel tubing is considered an ideal choice because of its properties that provide stability and durability in a variety of high-temperature and corrosive conditions.

The Polished Process:

The metal pipeline undergoes a surface polishing process that enhances its appearance and performance through mechanical or chemical treatments. This process involves two main methods: mechanical and chemical polishing.

Polished Stainless Pipe

Stainless steel polished pipes are used in a wide range of applications. In the chemical and petroleum industries, their excellent corrosion resistance makes them ideal for the transportation of corrosive liquids. In the food and beverage industry, the smooth surface of polished pipes helps to clean and sanitize, meeting stringent hygiene standards. In addition, stainless steel polished pipes are widely used in decorative and architectural applications, such as hotel lobbies and shopping mall display cases, adding beauty and ambience to the space with their elegant appearance and modernity.

With its excellent performance, elegant appearance and diverse applications, stainless steel polished pipes offer new possibilities and flexibility for a wide range of industries. No matter what your project needs are, polished pipes may be the ideal choice for you.

MTSCO has been engaged in the supply of industrial piping products for 17 years, and can provide all kinds of piping products and fittings made of stainless steel, such as austenitic 300 series, duplex steel, ferrite 400 series and so on.

From production to delivery are controlled by professional QC team to ensure the quality of products. Welcome to inquiry and feel the service and quality of MTSCO Pipeline!

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM A269 / ASME SA269 Stainless Steel Seamless Hydraulic Tube With Small Diameter

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Stainless steel seamless bright annealed tube’s f......

TP304 / 304L Stainless Steel Seamless Tube For Instrument With Bright Annealed Surface

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely a......

ASTM B163 / B423 ASME SB163 / SB423 Alloy 825 Nickel Alloy Seamless Tube

Features: Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments containing phosphoric and sulfuric acids, oxidizing environments containing nitric acid and nitrates, and pitting, crevice corrosion and intergranular corrosion. It has good mechanic......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語