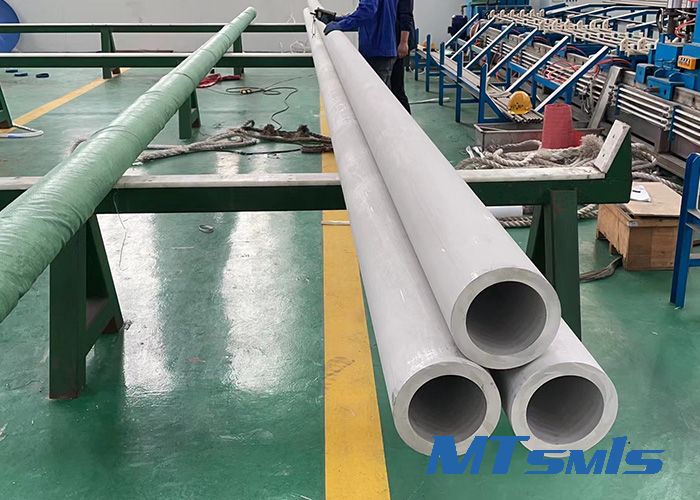

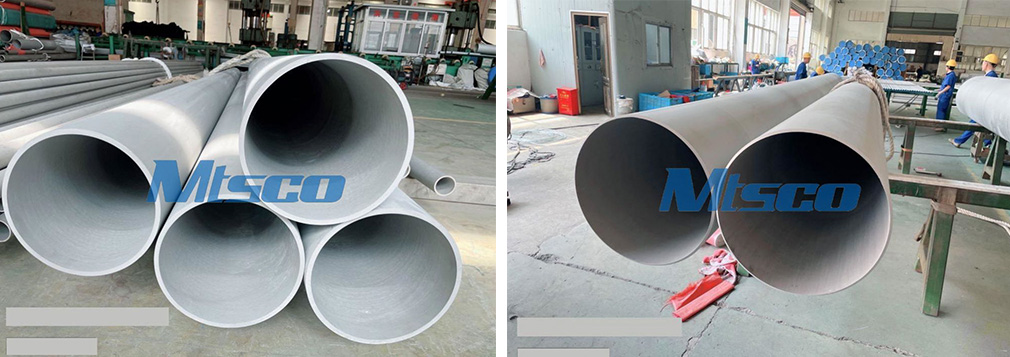

Alloy 254 SMO(6-moly) UNS S31254 6Mo Pipe

Alloy 254Mo, also known as UNS S31254 or F44, is a high alloy austenitic stainless steel. This material is specially added with a large amount of molybdenum, nickel, and copper, giving it excellent resistance to pitting and crevice corrosion, especially in harsh environments containing halides. Alloy 254Mo seamless pipe not only maintains excellent ductility and toughness at high temperatures, but also has high strength characteristics almost twice that of 3xx series austenitic stainless steel, making it an ideal choice for many high-end applications.

254smo is an austenitic stainless steel, also known as 6Mo steel or UNS S31254. It is a high alloy steel with excellent corrosion resistance and high temperature strength, widely used in chemical, marine, petroleum, mining and other fields.

Specifications of S31254 Pipe:

Grade | Standard | Outside Diameter | 8mm-711mm |

S31254 TP304 TP304L | ASTM-A312 | Wall Thickness | 1mm-50mm |

Length | ≤20m | ||

Inspection | Appearance/ Dimensional test, PMI; | ||

Certificates | ISO/PED/AD2000/TS | ||

Package | End protection/ Woven bags/ Wooden cases |

Chemical Composition of 254Mo/ 6Mo

Component | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | N |

Min | - | - | - | - | - | 19.5 | 17.5 | 0.5 | 6 | 0.18 |

Max | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 20.5 | 18.5 | 1 | 6.5 | 0.22 |

Application fields of 6mo pipe:

-Chemical industry: such as oil and gas processing equipment, storage and processing equipment for acidic media such as sulfuric acid and hydrochloric acid.

-Marine engineering: such as seawater distillers, seawater coolers, exposed components in seawater, etc.

-Mining field: including equipment for mining, refining, and processing metal ores.

-Food industry: such as food processing equipment, storage and transportation equipment, etc.

What is the pickling surface of the pipe?

The surface pickling process of stainless steel pipes involves treating the surface with an acidic solution, such as sulfuric or hydrochloric acid, to remove impurities like oxides, oil residue, and welding scales. This method cleanses the surface, eliminating oxide layers and providing a cleaner and smoother appearance to the stainless steel surface. This treatment enhances the corrosion resistance of the pipes and makes them more suitable for various applications, such as in chemical industries and oil processing. The pickled surface of stainless steel pipes typically exhibits increased luster, improving both the quality and appearance of the pipes.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

10BWG DN200 Stainless Steel Seamless / Welded Pipe With Cold Rolled

MTSCO is a leading manufacturer who is specialized in seamless stainless steel pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Seamless stainless steel pipes final surface are p......

12 Inch Sch40 TP347 / 347H Austenitic Stainless Steel Pipe With Annealed & Pickled Surface

MTSCO is a leading manufacturer who is specialized in seamless stainless steel pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Seamless stainless steel pipes final surface are p......

ASTM A312 S30403 / 1.4306 Stainless Steel Big Size Seamless Pipe For Transportation

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語