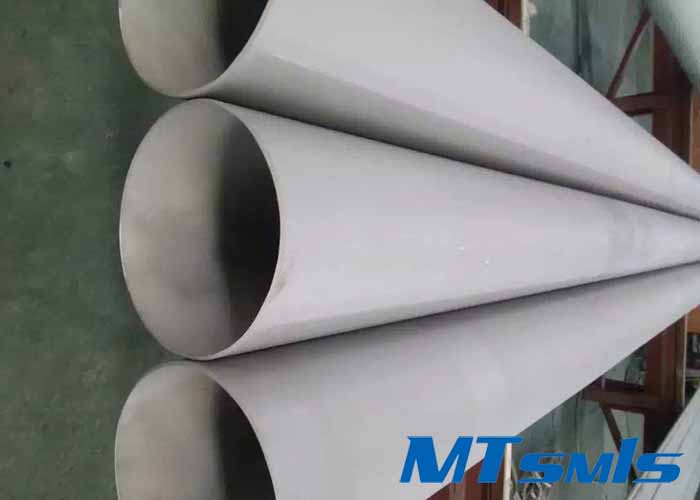

Inconel Alloy 602CA (UNS N06025) Seamless Pipe & Tube

Get Quote

Inconel Alloy 602CA (UNS N06025) Seamless Pipe & Tube

Alloy 602CA is an alloy with excellent high-temperature performance, and its chemical composition includes elements such as nickel, chromium, iron, aluminum, and carbon. It has excellent oxidation resistance, anti-oxidation peeling resistance, and high-temperature creep resistance, making it suitable for industrial applications in high-temperature environments. It can be used at extreme temperatures up to 2250 ° F (1232 ° C); Due to its excellent performance and supply in various forms such as plates, sheets, and round bars, RA 602 CA is increasingly being used in many harsh conditions, including radiation tubes, flame arresters with working temperatures up to 1204 ° C, furnaces for tool steel austenitization heat treatment, and other extremely high temperature applications.

Chemical composition of Alloy 602CA

Component | Fe | C | Si | Mn | P | S | Cr | Cu | Ti | Zr | Al | Y | More |

Min | 8 | 0.15 | - | - | - | - | 24 | - | 0.1 | 0.01 | 1.8 | 0.02 | Ni:allowance |

Max | 11 | 0.25 | 0.5 | 0.15 | 0.02 | 0.01 | 26 | 0.1 | 0.2 | 0.1 | 2.2 | 0.12 |

Shot Peening Surface of Alloy 602CA Pipe:

Surface shot peening of pipes is a surface treatment method in which powerful metal particles or abrasives are blasted at high speeds onto the surface of metal pipes through the use of shot peening equipment. This process removes oxidation, rust, oil and other impurities from the surface, thereby improving the quality and cleanliness of the metal surface.

The principle of the blasting process is to utilize the impact and friction of the abrasive material to effectively clean the metal surface, making it more uniform and smooth and improving the surface roughness of the metal. This not only helps to improve the surface quality of the metal, but also provides a better basis for subsequent painting, plating or other surface treatments.

Surface blasting is widely used in the manufacturing industry, especially in the preparation of metal pipes, steel structures and other metal products. This process helps to improve the corrosion resistance and extend the service life of metal products and also provides a better basis for adhesion to subsequent processes.

The Quality Control of MTSCO Seamless Pipe:

Quality Assurance for Raw Materials

Our raw materials, sourced from esteemed steel mills such as Baosteel and Tsingshan, undergo stringent warranty and PMI checks to ensure top-notch quality. Stringent PMI checks and other inspections guarantee compliance with material specifications.

Supervised Production Process

From cold rolling, cold drawing, annealing, to pickling and surface treatment, our seamless pipe manufacturing process is meticulously overseen. Skilled engineers, equipped with advanced tools, supervise each phase and capture detailed records through photography. Process cards guarantee precision and traceability throughout production.

Quality Assurance Before Shipment

Our dedicated QC team conducts comprehensive inspections, encompassing appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are carried out. We also welcome third-party evaluations (SGS, TUV, BV) and ensure secure packaging and container reinforcement to ensure product integrity during transportation.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

ASTM B619 Alloy G-35 / UNS N06035 Nickel Alloy Pipe

Application: Alloy G-35 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and s......

Cold Rolled ASTM B622 Seamless Nickel Alloy C276 Pipe

C-276 is a nickel-based alloy of nickel-molybdenum-chromium-iron-tungsten and is one of the most corrosion-resistant of modern metal materials. It is mainly resistant to wet chlorine, various oxidizing chlorides, chlorinated salt solutions, sulfuric acid, and oxidizing salts, and has good corrosion ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語