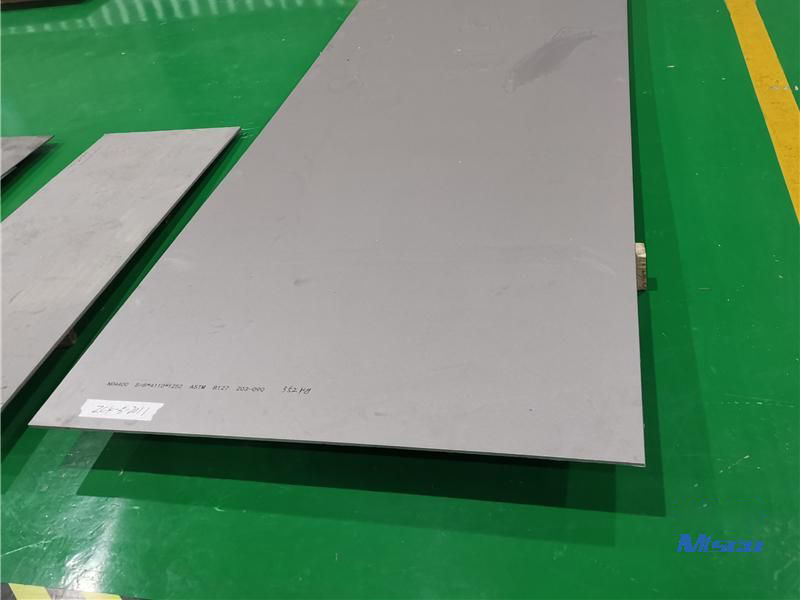

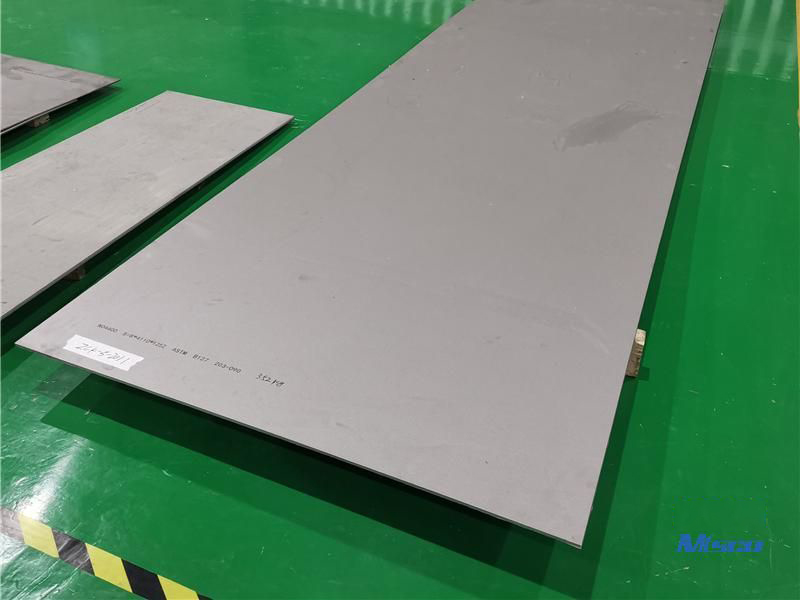

Alloy 601 / 625 N06600 / N06625 Nickel Alloy Sheet

MTNAPF11

Material: Alloy 600, UNSN06600; Alloy 601, UNSN06601; Alloy 625, UNSN06625;

Get Quote

Alloy 601 / 625 N06600 / N06625 Nickel Alloy Sheet

| Material Grade | Alloy 601 / 625 N06600 / N06625, Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc |

| Length | Normally fixed length 6m, can as per customer's requirement |

| Standard | ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc. |

Alloy 601 Chemical composition

| % | Ni | Cr | Fe | C | Mn | Si | S | Al | Cu |

| min | 58.0 | 21.0 | balance | 1.00 | |||||

| max | 63.0 | 25.0 | 0.10 | 1.00 | 0.50 | 0.015 | 1.70 | 1.00 |

Alloy 625 Chemical composition

| % | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

| min | 58.0 | 20.0 | 8.0 |

| 3.15 | ||||||||

| max | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Features:Alloy 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Alloy 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Applications: Chemical process industry and sea water application. Alloy 625 is used in short term applications at temperatures up to 816℃. For long term service, it is best restricted to a maximum of 593℃, because long term exposure above 593℃ will result in significant embrittlement.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

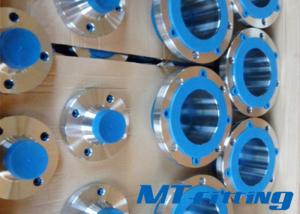

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

PN150 ASTM A366 Alloy K500 / UNS N05500 Nickel Alloy Socket Welding Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

Alloy 600 / 601 UNS N06600 / N06601 Nickel Alloy Round Rod / Bar

Material Grade: Alloy C-4/N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Length:can as per customer's requirement Standard:ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. MTSCO is a lead......

ASTM A182 / ASME SA182 600LB F304 / 304L Stainless Steel Socket Welded Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語