ASTM B163 Monel K500 Nickel Alloy K500 Seamless Pipe

SSNAP03

Price: From $36000-60000USD/TON

Material: Alloy K-500, UNS N05500; Alloy G-35, UNS N06035; Alloy S, UNS N06635;

Get Quote

Alloy K500 / UNS N05500 Nickel Alloy Pipe For Oil And Gas Industry

| Grade | Standard | Outside Diameter | 8mm-711mm |

| Alloy 600 Alloy 601 Alloy 625 Alloy 825 Alloy 800/800H/800HT Alloy C276 Alloy C22 Alloy 400 Alloy K500 Alloy 200 Alloy 201 ... | ASTM-B444 ASTM-B167/163 ASTM-B622 ASTM-B423 ...... | Wall Thickness | 1mm-50mm |

| Length | ≤20m | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

What is Features of Alloy K500?

Alloy K-500 combines Alloy 400's excellent corrosion resistance with greater strength and hardness as a result of adding aluminum and titanium and proper heat treatment to cause precipitation hardening. It is nonmagnetic at temperatures as low as -101℃. Alloy K-500 has excellent dimensional stability which is very useful in high precision devices. Like Alloy 400, it does not undergo ductile-to-brittle transition at cryogenic temperatures as low as that of liquid hydrogen. Its tensile and yield strengths increase while ductility and toughness are only slightly impaired.

Alloy K500 Chemical Composition:

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

| Alloy C276/N010276 | 0 | 0 | 1 | 0 | 0 | 14.5-16.5 | balance | 15-17 | - | - | - | - | - | - | 3 | 4-7 | 3.0-4.5 | 0 |

| Alloy 400/N04400 | 0 | 1 | 2 | - | 0 | - | ≥63 | - | - | - | 28-34 | - | - | - | - | 3 | - | - |

| Alloy K-500/N05500 | 0 | 1 | 2 | - | 0 | - | 63 | - | 0.35-0.85 | - | 27.0-33.0 | - | 2.3-3.15 | - | - | 2 | - | - |

| Alloy 200/N02200 | 0 | 0 | 0 | - | 0 | - | ≥99.6 | - | - | - | 0 | - | - | - | - | 0 | - | - |

| Alloy 201/N02201 | 0 | 0 | 0 | - | 0 | - | ≥99.9 | - | - | - | 0 | - | - | - | - | 0 | - | - |

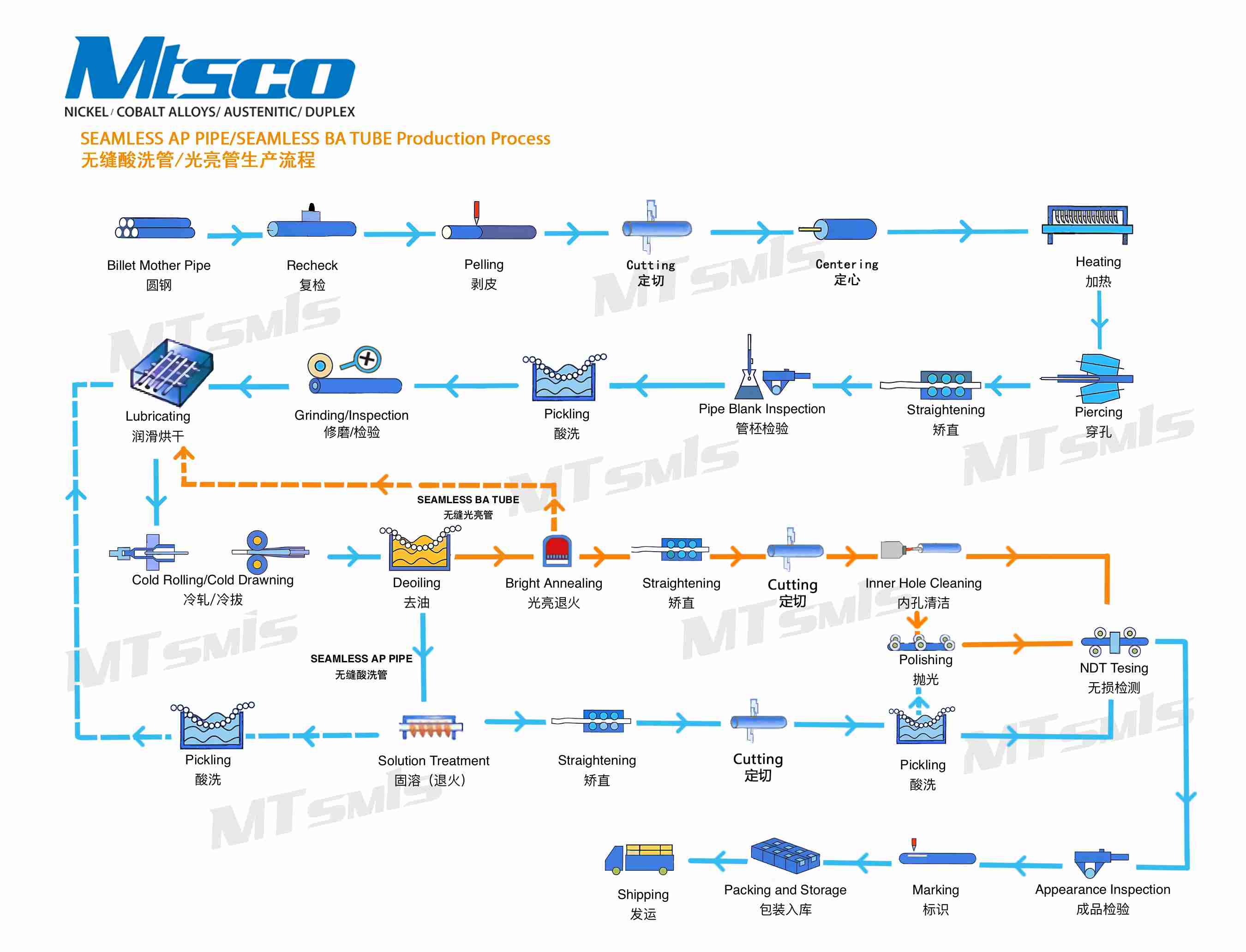

The Quality Control Of MTSCO for Alloy K500 Pipe:

Raw Material Quality Control

ASTM B167 Inconel 600 Nickel Alloy Seamless Pipe Tube

Inconel 600 seamless pipe provides excellent oxidation resistance at temperatures up to 2150°F (1177°C). However, it is susceptible to sulfide attack. This material can be annealed or stress relieved to provide lower strength, or strengthened by a pilgering process. Inconel 600 maintains excellent toughness even at higher strength conditions and remains tough at low temperatures. Inconel 600 seamless pipes are used in many different applications, including the chemical process industry, aerospace, food processing, electronics, oil and gas, and nuclear power generation. Its high-temperature oxidizing properties make it ideal for heat treaters, furnaces, incinerators, and other high-temperature equipment. Inconel 600 seamless pipe is an important part of industrial high-temperature piping systems because of its excellent high-temperature corrosion resistance. Proper selection of Inconel 600 pipe can effectively extend the service life of piping. If you need related solutions, please feel free to contact us!

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

ASTM B163 / B165 Alloy 400 / UNS N04400 Nickel Alloy Seamless Pipe

Monel 400, also known as Alloy 400, is a very well known nickel-copper alloy material. This alloy consists primarily of nickel (usually containing at least 63%) and copper, and also contains small amounts of iron, carbon, silicon, and manganese.Monel 400 is widely acclaimed for its excellent corrosi......

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語