Alloy L605/ UNS R30605 Cobalt Alloy Heat Resistance Forgings

Get Quote

Alloy L605/ UNS R30605 Cobalt Alloy Heat Resistance Forgings

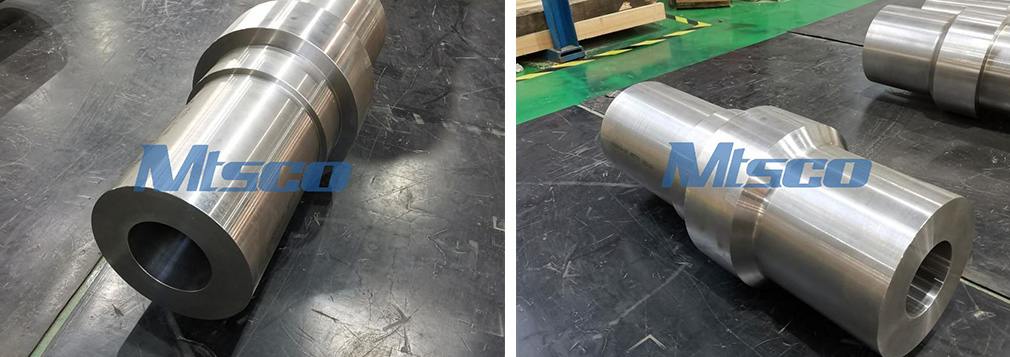

Alloy L605, also known as UNS R30605, is a highly specialized Cobalt-based alloy renowned for its exceptional strength, corrosion resistance, and high-temperature performance. With its unique combination of Cobalt, Chromium, Nickel, and Tungsten, Alloy L605 offers outstanding mechanical properties and remarkable resistance to oxidation and wear.This advanced alloy finds extensive applications in critical industries such as aerospace, gas turbines, and medical implants. Its exceptional strength-to-weight ratio makes it ideal for high-stress components and structural parts. Alloy L605 excels in extreme environments, maintaining its integrity under elevated temperatures and harsh conditions.

| Material | Cobalt Alloy |

| Grade | Hayness188,Haynes25(L-605),Alloy S-816,UMCo-50,MP-159,FSX-414, X-40,Stellite6B,etc |

| Standard | AMS 5608,5772,5796,5542/ ASTM F90 ,etc |

| Forged Type | Fittings, flanges, shafts, assemblies,etc |

| Packing | Pallet, Plywooden case, etc |

| Application | Aircraft forgings, marine forgings, weapons forgings, petrochemical forgings, nuclear power forgings, thermal power forgings, and hydropower forgings |

| Steel Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | Cu | Nb | Al | Co | Fe | W | Ta | La |

| Alloy 188/ UNS R30188 | 0.05-0.15 | 0.2-0.5 | 1.25 | 0.02 | 0.01 | 20.0-24.0 | 20.0-24.0 | 6.0-8.0 | 2.35-3.25 | 0.07 | 0.25-0.75 | 0.10-0.30 | balance | 3 | 13.0-16.0 | - | 0.03~0.12 |

| Alloy L-605/ UNS R30605 | 0.05-0.15 | 0.4 | 1 | 0.04 | 0.03 | 19.0-21.0 | 9.0-11.0 | - | - | - | - | - | balance | 3 | 14.0-16.0 | - | - |

| Alloy S-816 | 0.03 | 0.80-1.1 | 0.2 | 0.02 | 0.02 | 23.5-25.0 | - | - | - | - | - | - | 11.5~13.0 | Balance | 3.0-6.0 | 0.5-2.5 | - |

| Alloy 6B | 0.9-0.14 | - | 2 | - | - | 28-32 | 3 | 1.5 | - | - | - | - | balance | 3 | 3.5-5.5 | - | - |

| UMCo50 | 0.05-0.12 | 0.5-1.0 | 0.5-1.0 | 0.02 | 0.02 | 27-29 | - | - | - | - | - | - | 48-52 | Balance | - | - | - |

| FSX-414 | 0.2-0.3 | 1 | 1 | - | - | 28.5-30.5 | 9.5-11.5 | - | - | - | - | - | balance | 2 | 3.5-5.0 | 4.5-6.5 | - |

| MP-159 | 0.04 | 0.2 | 0.2 | 0.02 | 0.01 | 18.0-24.0 | balance | 6.00-8.00 | 2.50-3.25 | - | - | 0.10-0.30 | 34.00-38.00 | 8.00-10.00 | - | - | - |

The Advantageous Features of MTSCO Cobalt Alloy:

Our Cobalt-Based Forging Alloy L605 is a high-strength alloy that is highly resistant to corrosion, making it perfect for use in harsh environments. Our cobalt-based forging can be customized to meet your specific requirements, with a thickness range of 50mm to 500mm, a width range of 100mm to 2000mm, and a length range of 100mm to 6000mm. Our forging process ensures that the material is evenly distributed, making it perfect for high-stress applications such as aircraft engines, turbines, and chemical processing equipment.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

ASTM A182 / ASME SA182 F316L / 304L PN20-420 Stainless Steel Socket Welding Flange

1. Material Grade:WP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etc 2. Size: 1/2 to 48 Sch 5S to XXS 3. Standard: ASTM A403, ASTM A182 etc . 4. Process Method: Forged / Casting 1 ......

ASTM A182 F904L Flange, Stainless Steel 904L Flanges

MTSCO flange has a highly guaranteed supply chain. Since 2018, MTSCO flange business matured and invested in our own flange manufacturer-Yongheng Steel. The factory covers an area of 5,000㎡, with capacity of 300 tons/month. Yongheng is fully responsible for all flange orders from MTSCO, and operate......

ASTM B670 Alloy 718 / N07718 Nickel Allloy Sheet / Strip

1. Grade :Alloy 718 / N07718, Alloy C276/N10276, Alloy C-4/ UNS N06455,Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B333; ASTM B575; ASTM B16......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語