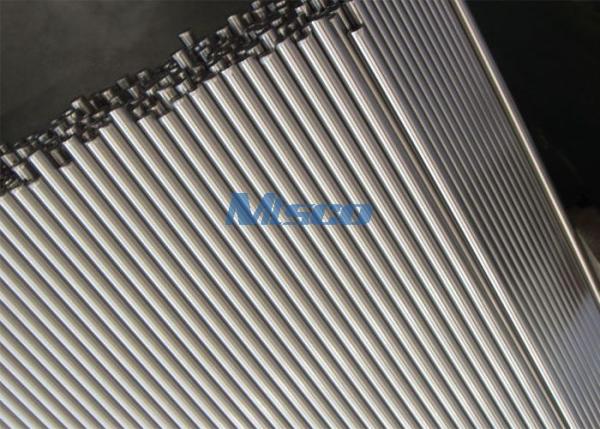

ASTM A182 F904L Flange, Stainless Steel 904L Flanges

| Commodity | Welded Neck, Slip on, Blind, Socket Weld, Plate... |

| Process Method | Forged |

| Grade | 904L, TP304/L, TP316/L, S31254, S32205, S32750, Alloy 600/601/625/825/C276/C22... Austenitic/ Duplex Steel/ Nickel/Cobalt Alloy |

| Standards | ASME B16.5/ 16.47/ 16.36, EN1092-1, DIN 2502... |

| Size Range | OD: 21.3-2032mm; DN15-DN2000; 1/2''-80'' |

| Tolerances | according to the specification or customer's request and drawings |

| Applications | oil & gas industry , chemical industry , electric power , boiler and heat exchanger , machinery , metallurgy , sanitary construction etc . |

Characteristics of Stainless Steel 904L material:

Excellent corrosion resistance: 904L exhibits extremely high corrosion resistance in various corrosive media, including sulfuric acid, phosphoric acid, and organic acids.

Good resistance to pitting and crevice corrosion: Especially in environments containing chloride ions, 904L exhibits superior resistance to pitting corrosion.

Non magnetic state: Non magnetic in annealed state, making it suitable for specific magnetic requirements.

High strength and good processing performance: Even under high temperature conditions, 904L maintains good strength and plasticity, making it easy to process and weld.

Application Area:

Chemical industry: Due to its excellent corrosion resistance, 904L is commonly used in chemical equipment, pipelines, heat exchangers, and storage tanks.

Oil and gas: suitable for equipment manufacturing in corrosive oil and gas environments.

Pharmaceutical industry: used for production equipment that meets high standards of hygiene and cleanliness requirements.

Ocean engineering: Due to its resistance to saltwater corrosion, it is commonly used in seawater treatment equipment and marine facilities.

Why Choose MTSCO Flange?

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

ASTM B670 Alloy 718 / N07718 Nickel Allloy Sheet / Strip

1. Grade :Alloy 718 / N07718, Alloy C276/N10276, Alloy C-4/ UNS N06455,Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B333; ASTM B575; ASTM B16......

ASTM A182 F304 / 304L Class150 Stainless Steel Slip On Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

F316L / 316 Stainless Steel Flange , PLRF ASTM A182 PN16 DN150 Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語