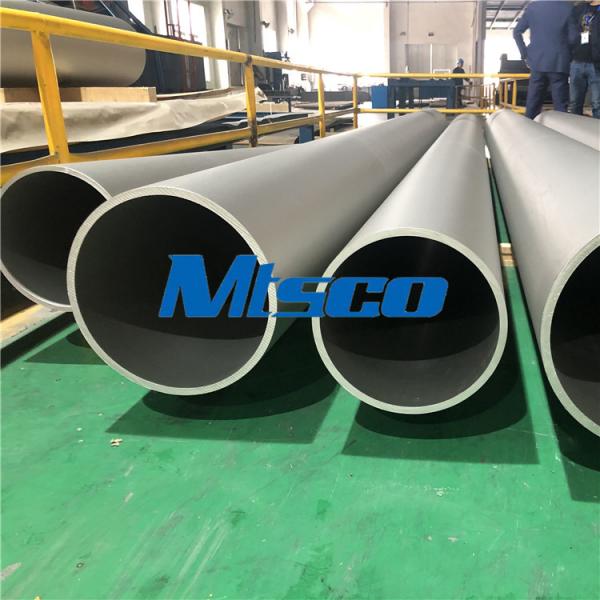

AMS 5581 Pipe, Inconel 625 Pipe, Nickel Alloy 625 Tube

SSNAP11

Material: Alloy 825, UNSN08825, 2.4858; Alloy 625, UNSN06625;

Get Quote

AMS 5581 Pipe, Inconel 625 Pipe, Nickel Alloy 625 Tube

Nickel Alloy 625 Pipe:

Nickel alloy 625 is known for its excellent corrosion resistance and high temperature performance. Containing alloying elements such as nickel and chromium, alloy 625 excels in both acidic and alkaline environments. Its corrosion resistance makes it widely used in areas such as chemical processing, marine engineering and the nuclear industry.625 material has excellent mechanical strength and heat resistance, making it suitable for requirements under high temperature and pressure conditions. Its good weldability and formability make it ideal for a wide range of industrial applications, including the petrochemical, aerospace and energy sectors.

Alloy 825 Pipe:

Apart from nickel being the primary alloying material in the alloy 825 electropolish pipe, the alloy also contains elements such as iron, chromium, titanium, molybdenum, and copper.

1. Grade : UNS N06625 , N06600 , N06601 , N07718 , N10276 , N08800 , N08825 ,N04400 ; etc

2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm

3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm

4 . Length : As customer's requirement

5 . Standard : AMS 5581F; ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

6 . Technology : Cold Drawn / Cold Rolled

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

| Alloy 718/N07718 | 0 | 0 | 0 | 0 | 0 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | 0.65-1.15 | 0 | 0 | 4.75-5.5 | 0.2-0.8 | 1 | - | - | - | - |

| Alloy 800/N08800 | 0 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 800H/N08810 | 0.05-0.10 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 825/N08825 | 0 | 1 | 1 | - | 0 | 19.5-23.5 | 38-46 | 2.5-3.5 | 0.6-1.2 | - | 1.5-3 | - | 0 | - | - | ≥22 | - | - |

What is AMS 5581F Grade?

Quality Control of MTSCO Seamless Pipe

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

ASTM B619 Alloy G-35 / UNS N06035 Nickel Alloy Pipe

Application: Alloy G-35 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and s......

ASTM A829 Alloy 400 6000MM Nickel Alloy Steel Seamless Pipe

Nickel alloy is one of MTSCO’s main products. We have finalized the integration flow process that covered everything from smelting to forging, machining to finished product. We consider that every kind of performance testing, checking, and analysis is very significant to assess the processing ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語