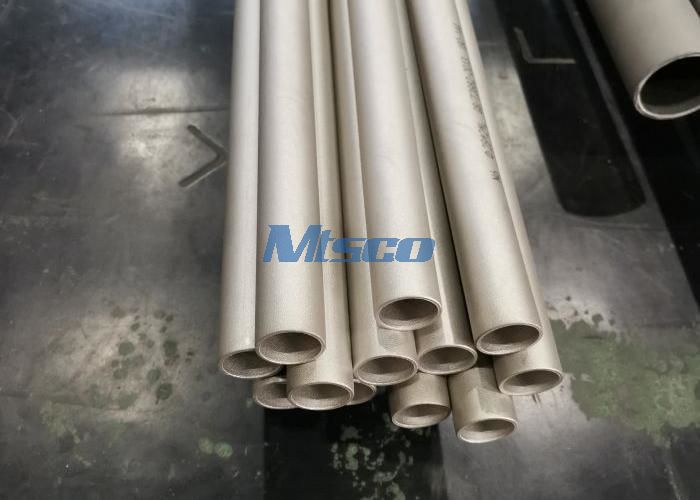

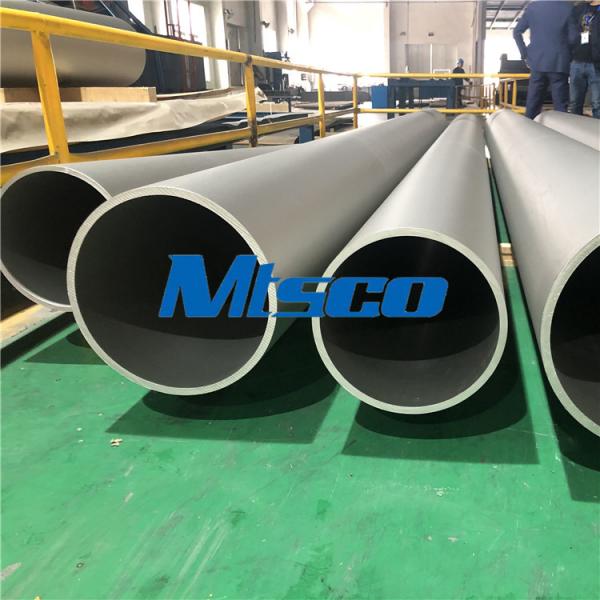

ASTM B407 / B829 Inc 800 / 800H / 800HT Nickel Alloy Seamless Pipe

SSNAWP06

Material: Alloy 800H, 800HT, UNSN08810&NO8811; Alloy 800, UNS N08800; Alloy 825, UNSN08825, 2.4858;

Get Quote

ASTM B407 / B829 Inc 800 / 800H / 800HT Nickel Alloy Seamless Pipe

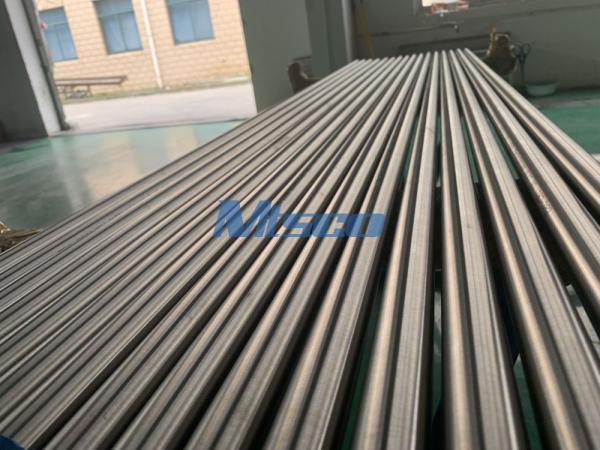

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . According to standard very strictly, nickel alloy tubes which produced by us always have correct OD and WT tolerance . Nickel alloy tubes have a very important position in thermocouple & cable industry .

Main market or alloy tube include Europe , Middle East , Southeast Asia , South America , etc . MTSCO has bright annealing alloy tube and pickling alloy tube . Compared these two kinds of tubes , bright annealed alloy tubes are more popular in the market . Because it has bright out and inner surface .

Specifications:

| Grade | Standard | Outside Diameter | 8mm-711mm |

| Alloy 600 Alloy 601 Alloy 625 Alloy 825 Alloy 800/800H/800HT Alloy C276 Alloy C22 Alloy 400 Alloy K500 Alloy 200 Alloy 201 ... | ASTM-B444 ASTM-B167/163 ASTM-B622 ASTM-B423 ...... | Wall Thickness | 1mm-50mm |

| Length | ≤20m | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

Chemical Composition:

| Grade | C | S | M | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb | Al | Co | Zr | Fe | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

| Alloy 718/N07718 | 0 | 0 | 0 | 0 | 0 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | 0.65-1.15 | 0 | 0 | 4.75-5.5 | 0.2-0.8 | 1 | - | - | - | - |

| Alloy 800/N08800 | 0 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 800H/N08810 | 0.05-0.10 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 825/N08825 | 0 | 1 | 1 | - | 0 | 19.5-23.5 | 38-46 | 2.5-3.5 | 0.6-1.2 | - | 1.5-3 | - | 0 | - | - | ≥22 | - | - |

Characteristics:

Excellent corrosion resistance: Alloy 800 nickel alloys are stable in many corrosive environments and perform particularly well in environments containing sulfides, chlorides and carbides.

Good high-temperature performance: This material has excellent strength and oxidation resistance at high temperatures, making it suitable for applications that operate at high temperatures for extended periods of time.

High stress corrosion cracking resistance: Alloy 800 exhibits excellent stress corrosion cracking (SCC) resistance in certain environments, such as alkaline media.

Good Mechanical Properties: Cold rolled Alloy 800 piping has higher strength and better surface finish for precision applications.

Areas of Application:

Petrochemical industry: for piping and heat exchangers in petroleum and chemical processing equipment, especially in environments handling highly corrosive substances.

Power plants: in nuclear power plants and conventional thermal power plants for components of steam generators and cooling systems to withstand high temperatures and corrosive environments.

Environmental equipment: In exhaust gas treatment systems and desulfurization plants, Alloy 800 piping is widely used for its corrosion resistance.

Aerospace: In aero-engines and space exploration equipment, for components that require high-temperature and high-strength materials.

Offshore: Alloy 800 piping is used in offshore platforms, submarines and other marine structures to resist seawater corrosion and provide long-term durability.

Food processing industry: Alloy 800 piping is used in heat exchangers and conveying systems in food and beverage processing to ensure food safety due to its excellent corrosion resistance.

Refining Industry: In the refining process, Alloy 800 piping is used in cracking units and other critical equipment to withstand extreme thermal loads and corrosive chemicals.

Textile industry: Alloy 800 piping is used in the heat treatment components of textile machinery to ensure efficient operation of the machinery and stability of the production line.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

Cold Rolled ASTM B622 Seamless Nickel Alloy C276 Pipe

C-276 is a nickel-based alloy of nickel-molybdenum-chromium-iron-tungsten and is one of the most corrosion-resistant of modern metal materials. It is mainly resistant to wet chlorine, various oxidizing chlorides, chlorinated salt solutions, sulfuric acid, and oxidizing salts, and has good corrosion ......

Alloy 31 Pipe, ASTM B622 UNS N08031 Seamless Nickel Alloy Pipe

Why Choose MTSCO Nickel Alloy Seamless Pipe? Huxin Pipe, a seamless steel pipe manufacturer owned by MTSCO Investments, is trusted for its 36 years of experience in pipe manufacturing. The factory not only supplies regular sized pipes, but can also provide extended pipe lengths of 18 and 25 metre......

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語