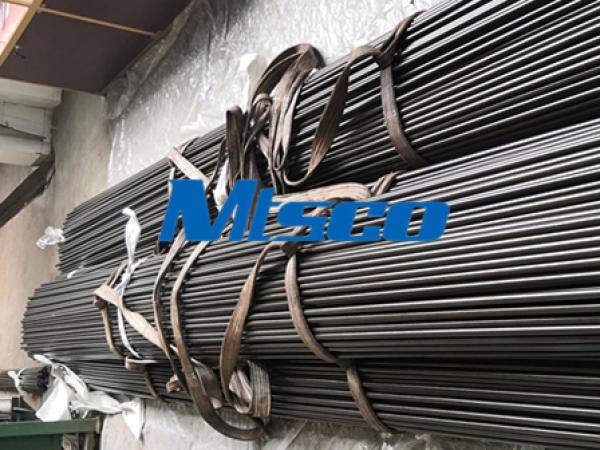

ASTM A268 Ferritic Stainless Steel Seamless / Welded 409 Tube

409 Tube:

409 stainless steel tube is especially useful for applications where oxidation or corrosion protection beyond the capacity of carbon steel and some coated steels is needed.

Current applications include automotive and truck exhaust systems, including tubular manifolds; agricultural spreaders, gas turbine exhaust silencers, and heat exchangers. It’s also useful for “difficult-to-form” hardware such as fuel fillers. 409 is a titanium stabilized ferritic stainless steel.

409 Tube Material Grade:

| Grade | – | C | Mn | Si | P | S | Cr | Ni | Ti |

| A268 409 | min. max. | – 0.08 | – 1.00 | – 1.00 | – 0.045 | – 0.030 | 10.5-11.7 | – 0.50 | 6C-0.75 |

409 Tube Specifications:

| Specifications | ASTM A268 |

| SS 409 Tubes Size | 20 (mm) – 219(mm) |

| Thickness | 1 (mm) to 20 (mm) |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round Tubes, Custom Tubes, Square Tubes, Rectangular Tubes, “U” Shape, Hydraulic Tubes |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

409 Tube Corrosion Resistance:

Grade 409 resists atmospheric and exhaust gas corrosion. A light surface rust will form in most atmospheres; this rust retards further corrosion but makes the surface undesirable for decorative applications. The corrosion resistance is about the same as that of 3CR12 and the 12% chromium martensitic grades such as 410, and inferior to the 17% chromium grade 430.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Ferritic Stainless Steel

ASTM A268 17.1mm*2.31mm Stainless Steel 410S Tube For Industry

Alloy 410S (UNS S41008) is a low carbon, non–hardening modification of Alloy 410 (UNS S41000) the general purpose 12% chromium martensitic stainless steel. The low carbon and a small alloy addition ...

ASTM A268 Stainless Steel 430 Tube With Pickling&Anealed Surface

430 stainless steel pipe is a ferritic stainless steel pipe that meets the ASTM A268 standard. It has good corrosion resistance and is suitable for weakly corrosive environments....ASTM A268 TP410 Stainless Steel Seamless Pipe For Industry

TP410 is the basic and typical martensitic steel alloy. It has the high hardness with good ductility and a relatively limited corrosion-resistant capability.TP410 material does not have the nickel content and has a relatively low material cost. Mtsco supply TP410 Stainless Steel Seamless Pip......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語