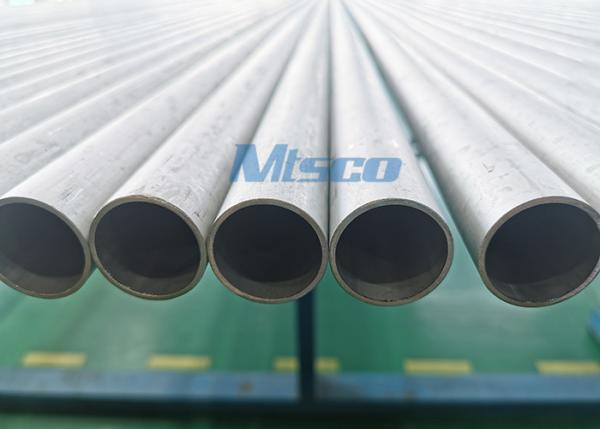

ASTM A269 TP347/TP347H Stainless Steel Heat Exchanger Tube

SSHE11

Price: From $5900-12000USD/TON

Material: 347/347H,1.4550,1.4961;

Get Quote

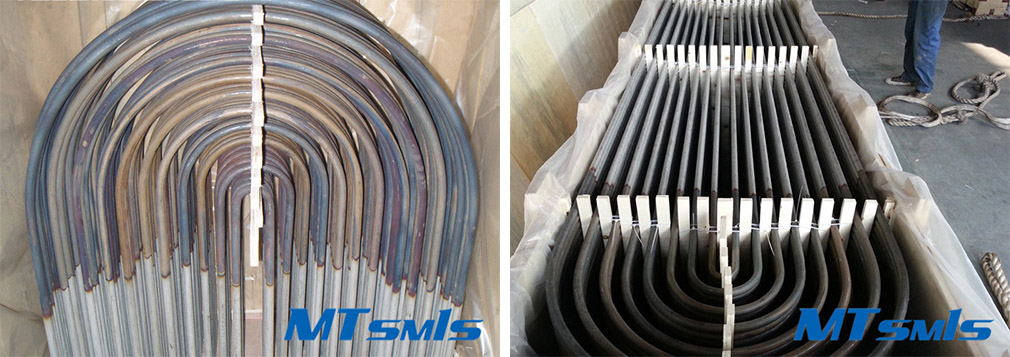

ASTM A269 TP347 / TP347H Heat Exchanger Tube Stainless Steel U Bend Tube

Specifications of Stainless Steel Heat Exchanger Tube:

| Grade | Standard | Outside Diameter | 3.18mm-38mm |

| TP304 TP304L TP316 TP316L TP317L TP321 TP321H TP347 TP347H TP904L | ASTM-A269 ASTM-A213 ASTM-B268 ASTM-B444 ASTM-B167/163 ASTM-B622 ASTM-B423 ...... | Wall Thickness | 0.5mm-3mm |

| Length | ≤30m | ||

| Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

What is Stainless Steel Heat Exchanger Tube?

Stainless steel heat exchanger U-tubes are a specific shape of tubing that is used in many industrial heat exchangers.The design of the U-tubes allows the tubing to be bent into a U-shape, resulting in a larger heat exchange area in a smaller space. It is extremely resistant to corrosion. Stainless steel can easily cope with high pressure and high temperature environments. These U-shaped tubes are also cleverly arranged in the heat exchanger. They are bundled in a tube sheet and then placed inside the housing. The whole setup allows one fluid to flow through the U-tubes while another fluid flows through the outside of the tubes, exchanging heat through the walls.

Quality Control of MTSCO Heat Exchanger Tube:

Physical Property of 347 Heat Exchanger Tube:

| Steel grade | Physical Property | |||

| Y.S | T.S | EL. | HRB | |

| 304 | ≥205 | ≥515-1035 | ≥40 | ≤92 |

| 304L | ≥205 | ≥520 | ≥40 | ≤90 |

| 316 | ≥620 | ≥310 | ≥30 | ≤95 |

| 316L | ≥480 | ≥177 | ≥40 | ≤90 |

| 321 | ≥205 | ≥515 | ≥40 | ≤95 |

| 347 | ≥205 | ≥515 | ≥40 | ≤92 |

Heat Exchanger Tube, High Performance Tubes for Heat Exchanger

With the increasing energy constraints and environmental issues, the efficiency and energy-saving nature of heat exchanger tubes are becoming more and more important.

In the modern industrial field, the industrial heat exchanger tube is undoubtedly one of the crucial core elements, which plays a role similar to that of the human blood vessels, so that the heat energy can be efficiently utilized in the industrial production process. With the increasing energy constraints and environmental issues, the efficiency and energy-saving nature of heat exchanger tubes are becoming more and more important. The application of heat exchanger tube mainly includes the following aspects:

Heat exchanger: A heat exchanger is a device used to transfer heat in the industrial production process, which can separate the hot fluid from the cold fluid and exchange heat through the pipe. Heat exchanger tubes can enhance the performance of heat exchangers and save energy by improving heat transfer efficiency and reducing heat loss.

Evaporator: Evaporators are used to convert liquids into vapors. Heat exchanger tubes can be used as heating tubes or condenser tubes in the evaporator to regulate fluid temperature and pressure by controlling the flow rate and flow of fluids in the tubes.

Condenser: Condenser is used to convert vapors into liquids. Heat exchanger tubes can be used as condenser tubes or drain tubes in condensers, which can improve the efficiency and life of the condenser by increasing the cooling efficiency and preventing scaling and clogging.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

ASTM A269 TP347 / TP347H Heat Exchanger Tube Stainless Steel U Bend Tube

Stainless steel heat exchanger U-tubes are a specific shape of tubing that is used in many industrial heat exchangers.The design of the U-tubes allows the tubing to be bent into a U-shape, resulting in a larger heat exchange area in a smaller space. It is extremely resistant to corrosion. Stainless ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語