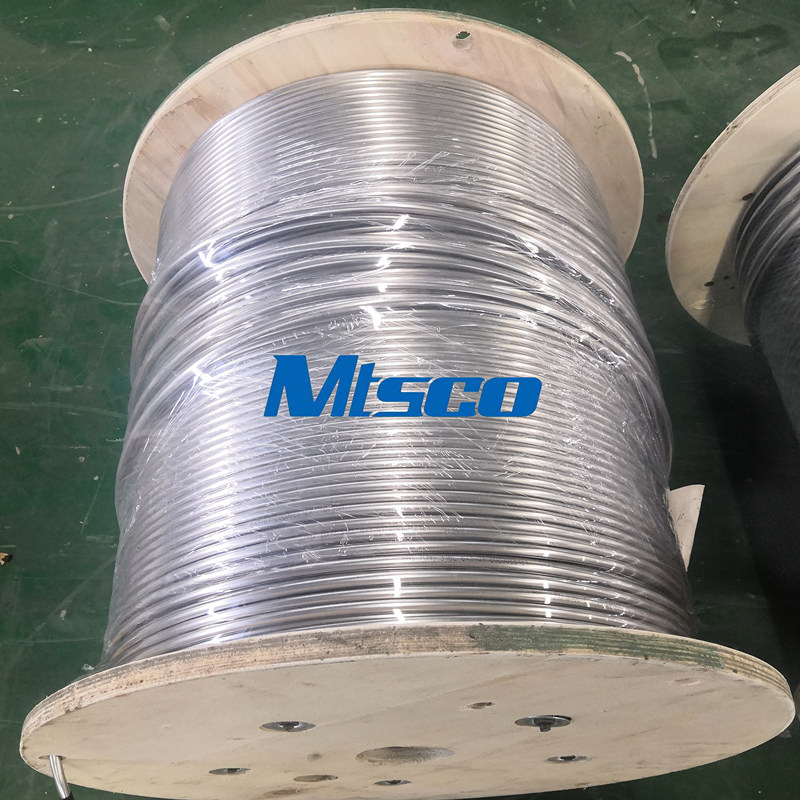

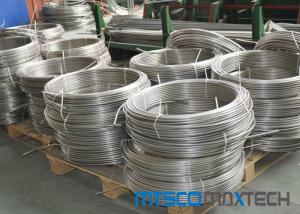

ASTM A789 Duplex Steel 2205 Coiled Tube For Chemical Injection

2205 Coiled Tube:

Alloy 2205 is duplex stainless steel with high general, localized and stress corrosion resistance properties, high strengths, and outstanding impact toughness. Developed primarily to combat common corrosion problems. Duplex is superior to 316L or 317L austenitic stainless steel in most corrosive environments.

The duplex alloy 2205 structure consists of austenite pools surrounded by continuous ferrite phase and contains approximately 45% ferrite. It is the most widely use grade in the duplex family of stainless steels.

2205 Coiled Tube Basic Information:

Grade

| 2205 (If you have special material requirements, please tell us) |

Standard | ASTM A789 |

Size | OD : 4.76 - 25.4mm WT : 0.71 - 2.11mm Length : >1000Meters 4.76 * 0.71mm / 4.76 * 0.89mm / 4.76 * 1.24mm6 * 1mm / 6 * 1.5mm 6.35 * 0.71mm / 6.35 * 0.89mm / 6.35 * 1.24mm / 6.35 * 1.65mm 7.94 * 0.71mm / 7.94 * 0.89mm / 7.94 * 1.24mm / 7.94 * 1.65mm 9.53 * 0.71mm / 9.53 * 0.89mm / 9.53 * 1.24mm / 9.43 * 1.65mm 10 * 1mm / 10 * 1.5mm 12 * 1mm / 12 * 1.5mm / 12 * 2mm 12.7 * 0.71mm / 12.7 * 0.89mm / 12.7 * 1.24mm / 12.7 * 1.65mm / 12.7 * 2.11mm 14 * 1mm / 14 * 1.5mm / 14 * 2mm 15.88 * 0.89mm / 15.88 * 1.24mm / 15.88 * 1.65mm / 15.88 * 2.11mm 16 * 1mm / 16 * 1.5mm / 16 * 2mm 19.05 * 0.89mm / 19.05 * 1.24mm / 19.05 * 1.65mm / 19.05 * 2.11mm 25.4 * 0.89mm / 25.4 * 1.24mm / 25.4 * 1.65mm / 25.4 * 2.11mm |

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

2205 Coiled Tube Inspection & Test

1 .100 % PMI, Spectro Chemical Analysis Test for Raw Material

2 .100 % Dimension & Visual Examination

3 . Mechanical Properties Test Include Tension Test, Flaring Test ( For Seamless tube/pipe) / Flange Test ( For Welded Pipe & Tube ), Hardness Test, Reversed Flattening Test

4 .100 % Hydrostatic Test or 100 % NON - DESTRUCTIVE Test ( ET or UT )

5 . Radiographic Test for Welded Pipe ( shall be accordance with specification, or shall be as agreed upon between the purchaser and vendor )

6 . Straightness Test ( optional )

7 . Roughness Test ( optional )

8 . Intergranular Corrosion Test ( optional )

9 . Impact Test ( optional )

10 . Grain Size Determinations ( optional )

NOTES: ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

S31803 ASTM A789 / A790 Duplex Steel Coiled Tube For Chemical Industry

Inspection & Test 1 .100 % PMI , Spectro Chemical Aanlysis Test for Raw Material 2 .100 % Dimension & Visual Examination 3 . Mechanical Properties Test Include Tension Test,Flaring Test ( For Seamless tube / pipe ) / Flange Test ( For Welded Pipe & Tube ) , Hardness Test , Reversed Flatteni......

3 / 8 Inch 17.1mm TP321 / 321H Stainless Steel Seamless Coiled Tubing With Cold Rolled

1 . Our company has been dedicated to producing seamless coiled tubing since 2014 , owning complete producing technology and abundant managing experience . 2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc . 3 ......

S31700 / TP317 12.7mm Bright Annealed Stainless Steel Seamless Coiled Tube

MTSCO is a leading manufacturer who is specialized in seamless coiled tubing produce . Stainless steel seamless coiled tubing final surface is bright annealed. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. They are very popular in military, ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語