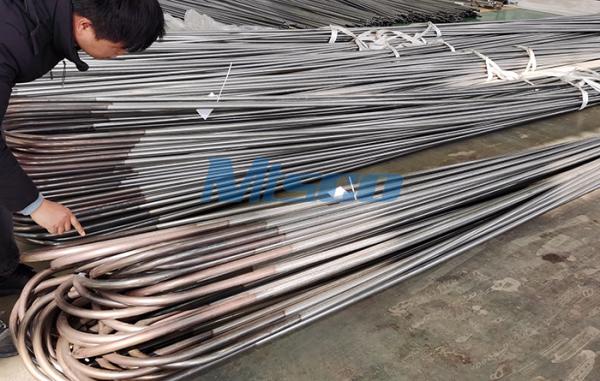

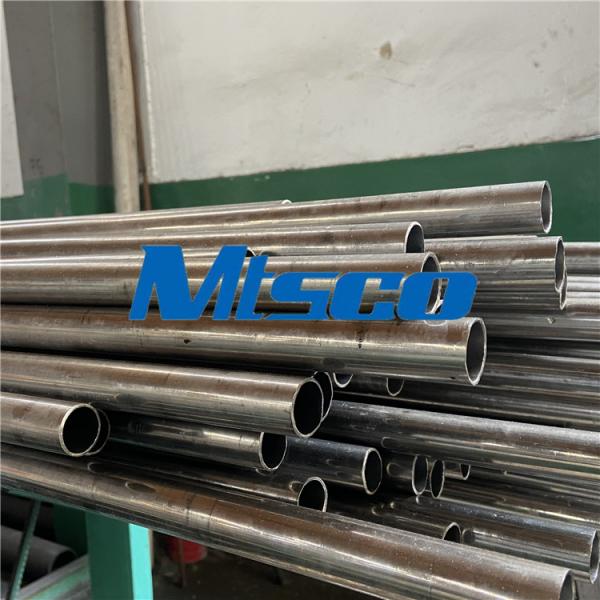

ASTM A790 / ASME SA790 S31803 / 2205 Duplex Steel Tube For Oil And Gas

SSDST12

Price: From $5500-8000USD/TON

Material: S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get Quote

ASTM A790 / ASME SA790 S31803 / 2205 Duplex Steel Tube For Oil And Gas

Super duplex stainless such as duplex is a mixed microstructure of austenite and ferrite which has improved strength over ferritic and austenitic steel grades . The main difference is super duplex has a higher molybdenum and chromium content which gives the material greater corrosion resistance . Super duplex has the same benefits as its counterpart - it has lower production costs when compared with similar ferritic and austenitic grades and due to the materials increased tensile and yield strength , in many cases this gives the purchaser the welcomed option of purchasing smaller thicknesses without the need to compromise on quality and performance .

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

| Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

| Package | Iron case; woven bag or as per customer’s requirement |

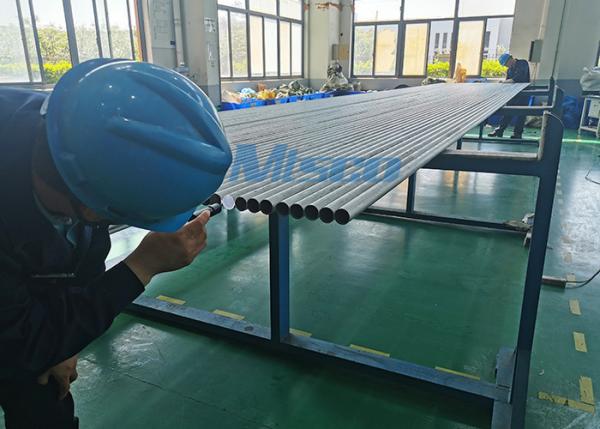

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | |

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | |

| Chemical Analysis(Photoelectric Emission Spectroscopic) | |

| Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Features :

1 . Outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments, with critical pitting temperature exceeding 50°C

2 . Excellent ductility and impact strength at both ambient and sub-zero temperatures

3 . High resistance to abrasion, erosion and cavitation erosion

4 . Excellent resistance to stress corrosion cracking in chloride containing environments

5 . ASME approval for pressure vessel application

| ASTM A790 Standard |

| 2205 / S32750 Elements |

| (C) Carbon , max : 0.030 |

| (Mn) Manganese , max : 1.20 |

| (P) Phosphorus , max : 0.035 |

| (S) Sulfur , max : 0.020 |

| (Si) Silicon , max : 0.80 |

| (Ni) Nickel : 6.0 - 8.0 |

| (Cr) Chromium : 24.0 - 26.0 |

| (Mo) Molybdenum : 3.0 - 5.0 |

| (Fe) Iron : -- |

| (Cu) Copper , max : 0.5 |

| (N) Nitrogen : 0.24 - 0.32 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語