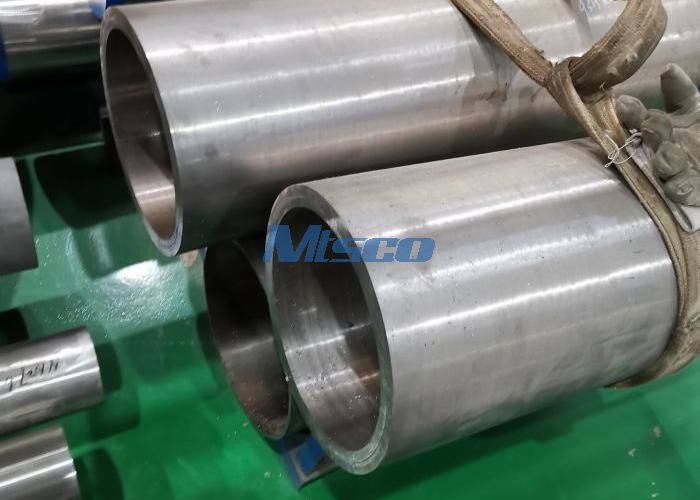

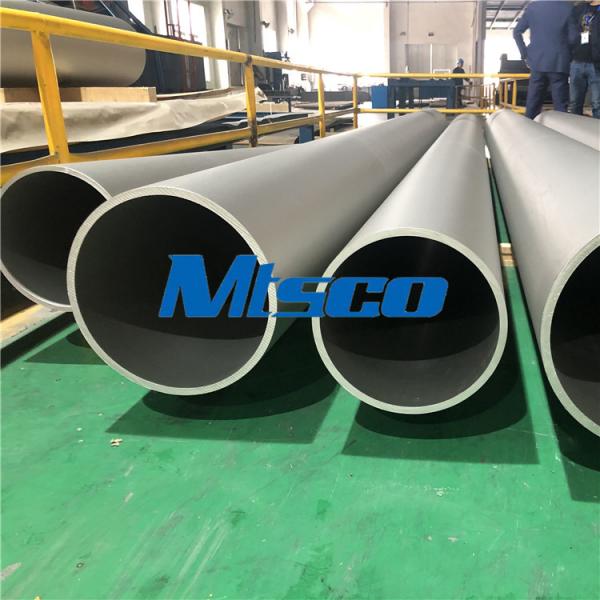

ASTM B163 Nickel Alloy 400/UNS N04400 Seamless Pipe

SSNAP02

Price: From $24000-40000USD/TON

Material: Alloy 400, UNS N04400; Alloy 230, UNS N06230;

Get Quote

ASTM B163 / B165 Monel 400 / UNS N04400 Nickel Alloy Seamless Pipe

Chemical Composition of Nickel Alloy Pipe:

Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb | Al | Co | Zr | Fe | Tu | Va |

Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

Alloy 825/N08825 | 0 | 1 | 1 | - | 0 | 19.5-23.5 | 38-46 | 2.5-3.5 | 0.6-1.2 | - | 1.5-3 | - | 0 | - | - | ≥22 | - | - |

Alloy B/N10001 | 0 | 1 | 1 | 0 | 0 | 1 | - | 2.8-3.3 | - | - | - | - | - | 25 | - | 4-6 | - | - |

Alloy C22/N06022 | 0 | 0 | 1 | 0 | 0 | 20.0-22.5 | balance | - | - | - | - | - | - | 25 | - | 2-6 | - | - |

Alloy C276/N010276 | 0 | 0 | 1 | 0 | 0 | 14.5-16.5 | balance | 15-17 | - | - | - | - | - | - | 3 | 4-7 | 3.0-4.5 | 0 |

Alloy 400/N04400 | 0 | 1 | 2 | - | 0 | - | ≥63 | - | - | - | 28-34 | - | - | - | - | 3 | - | - |

Features of Nickel Alloy 400:

Monel 400, also known as Alloy 400, is a very well known nickel-copper alloy material. This alloy consists primarily of nickel (usually containing at least 63%) and copper, and also contains small amounts of iron, carbon, silicon, and manganese.Monel 400 is widely acclaimed for its excellent corrosion resistance, especially to seawater and environments containing chlorides.

Its key properties include:

Strong corrosion resistance: Nickel alloy 400 shows excellent corrosion resistance in a wide range of corrosive media, especially seawater, sulfuric acid, hydrofluoric acid and hydrochloric acid.

Good Temperature Resistance: This material is stable in a wide range of temperatures, working at subfreezing temperatures as well as withstanding temperatures as high as 538°C (~1000°F).

Excellent mechanical properties: Nickel alloy 400 has good strength and toughness even at low temperatures, which makes it reliable in cold environments.

Good weldability: This material can be processed by conventional welding, brazing, and soldering processes, facilitating complex applications.

Alloy 400 Chemical composition:

% | Ni | Cu | Fe | C | Mn | Si | S |

min | 63.0 | 28.0 | - | - | - | - | - |

max | - | 34.0 | 2.5 | 0.30 | 2.00 | 0.50 | 0.024 |

Quality Control of MTSCO Nickel Alloy Pipe:

1. Quality Control of Raw Materials

MTSCO pipe raw materials come from large steel mill such as Baosteel and Tsingshan. Each batch of raw materials requires a warranty and PMI to ensure the quality. We will conduct PMI and other inspections to ensure that they meet the material requirements

2. Process Control During Production

MTSCO seamless pipe production processes include cold rolling, cold drawing, annealing, pickling, surface treatment, etc. Each process is equipped with advanced production equipment, and we have experienced engineers and technicians. Each link is supervised by them and photographed for archiving. We use process cards to ensure the accuracy and traceability of the entire production process.

3. Quality Control Before Shipment

MTSCO have a professional QC team that conducts a series of inspections and experiments on products, including appearance, PMI, size, quantity, and other inspections. At the same time, we also conduct mechanical, hardness, ultrasonic testing, eddy current testing, hydraulic testing, and other tests. In addition, we also accept third-party testin, such as SGS, TUV, and BV. Before shipping, we use appropriate and safe packaging methods and take measures such as container reinforcement to ensure that the goods are not damaged during transportation.

ASTM B167 Inconel 600 Nickel Alloy Seamless Pipe Tube

Inconel 600 seamless pipe provides excellent oxidation resistance at temperatures up to 2150°F (1177°C). However, it is susceptible to sulfide attack. This material can be annealed or stress relieved to provide lower strength, or strengthened by a pilgering process. Inconel 600 maintains excellent toughness even at higher strength conditions and remains tough at low temperatures.

Inconel 600 seamless pipes are used in many different applications, including the chemical process industry, aerospace, food processing, electronics, oil and gas, and nuclear power generation. Its high-temperature oxidizing properties make it ideal for heat treaters, furnaces, incinerators, and other high-temperature equipment.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

ASTM B622 / B619 Alloy C-2000 / UNS N06200 Nickel Alloy Pipe

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

ASTM A829 Alloy 400 6000MM Nickel Alloy Steel Seamless Pipe

Nickel alloy is one of MTSCO’s main products. We have finalized the integration flow process that covered everything from smelting to forging, machining to finished product. We consider that every kind of performance testing, checking, and analysis is very significant to assess the processing ......

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語