ASTM B443 / ASME SB443 Alloy 625 Nickel Alloy Sheet For Oil Industry

MTNAPF13

Material: Alloy 601, UNSN06601; Alloy 625, UNSN06625; Alloy 718, UNS N07718; Alloy 617, UNS N06617;

Get Quote

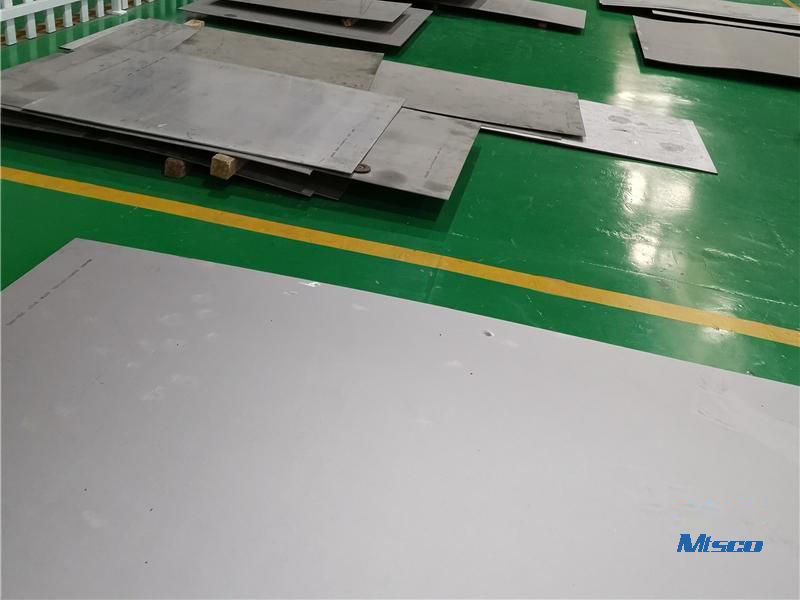

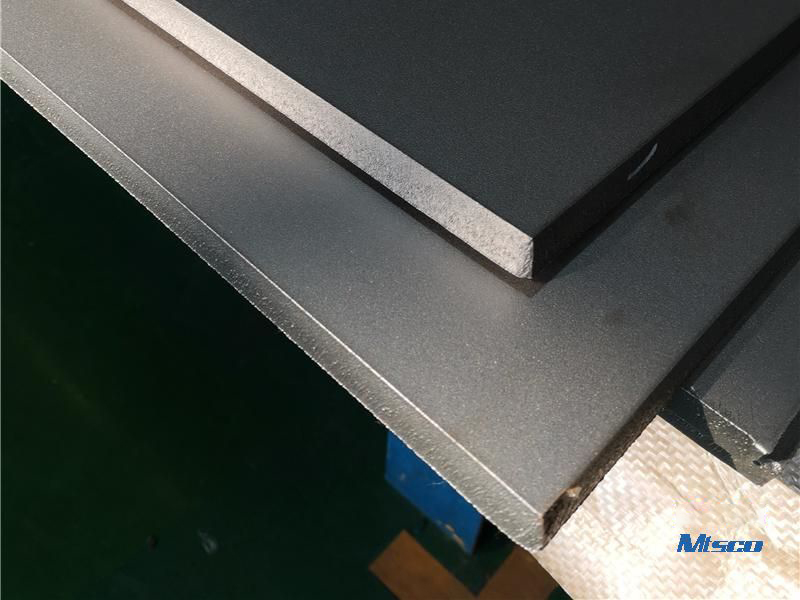

ASTM B443 / ASME SB443 Alloy 625 Nickel Alloy Sheet For Oil Industry

1. Grade: Alloy 625, Alloy C276/N10276, Alloy C-4/ UNS N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675,

Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc

2 . Length : As customer's requirement

3 . Standard : ASTM B333; ASTM B575; ASTM B168; ASTM B443; ASTM B670 etc.

4. Technology : Cold Drawn / Cold Rolled

Chemical composition

| % | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

| min | 58.0 | 20.0 | 8.0 | 3.15 | |||||||||

| max | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Physical properties

| Density | 8.44 g/cm3 |

| Melting range | 1290-1350℃ |

Features: Alloy 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Alloy 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Applications: Chemical process industry and sea water application. Inconel 625 is used in short term applications at temperatures up to 816℃. For long term service, it is best restricted to a maximum of 593℃, because long term exposure above 593℃ will result in significant embrittlement.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

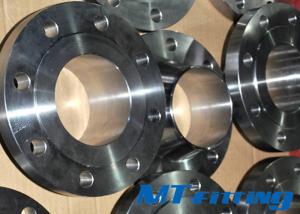

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

High Temperature Alloy GH3030 GH30 XH78T Nickel Alloy Sheet/Plate

The Advantageous Features of Alloy GH3030 Plate: GH3030 is a solid solution strengthened nickel-based high temperature alloy with the following characteristics: Stable organization, small aging tendency. Good oxidation resistance, suitable for high temperature environment. Good machinability......

ASTM B443 / ASME SB443 Alloy 625 Nickel Alloy Sheet For Oil Industry

1. Grade: Alloy 625, Alloy C276/N10276, Alloy C-4/ UNS N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B333; ASTM B575; ASTM B16......

Alloy 600 / 601 UNS N06600 / N06601 Nickel Alloy Round Rod / Bar

Material Grade: Alloy C-4/N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Length:can as per customer's requirement Standard:ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. MTSCO is a lead......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語