ASTM B444 UNS N06625 Inconel 625, ASME SB444 Alloy 625

What are the properties of Inconel 625 (Alloy 625) under the standard?

Inconel Alloy 625 is particularly well suited for applications such as aerospace where high strength and fatigue resistance are required, as well as excellent resistance to chloride corrosion and stress corrosion cracking.

Inconel Alloy 625 alloy is a solid solution strengthened nickel-based deformation high temperature alloy with molybdenum and niobium as the main reinforcing elements. It has excellent corrosion and oxidation resistance, good tensile and fatigue properties from low temperatures up to 980°C, and is resistant to stress corrosion in a salt spray atmosphere.

In terms of chemical composition, Inconel 625 alloys typically follow the ASTM B443/B444 standards, which specify the range and requirements for the content of nickel, chromium, molybdenum, iron, copper, titanium, aluminum and silicon in the alloy. For example, the alloy should contain at least 58% nickel, 15% chromium, 4% molybdenum and 0.2% niobium. In addition, iron, carbon and other impurity levels should be kept within certain limits.

In terms of mechanical properties, Inconel Alloy 625 alloy's implementation standard also follows the ASTM B443/B444 standard, which has clear requirements for the alloy's tensile strength, yield strength, elongation, hardness and other aspects. At room temperature, the yield strength of the alloy should be not less than 250 MPa, the tensile strength should be not less than 450 MPa, and the elongation should be not less than 25%. In addition, the ASTM B 446 standard also specifies the mechanical property requirements of the alloy at different temperatures, such as low-temperature toughness and high-temperature creep.

Inconel Alloy 625 is an austenitic superalloy with nickel as the main component. Derived from the strengthening effect of molybdenum and niobium solid solutions contained in nickel-chromium alloys, it is widely used in aerospace industry for its ultra-high strength and extraordinary fatigue resistance at low temperatures up to 1093°C. Although the alloy is designed for strength in high temperature environments, the high chromium and molybdenum content of the alloy exhibits excellent corrosion resistance to a wide range of corrosive media, from highly oxidizing environments to general corrosive environments, with high resistance to etch loss spots and fission corrosion. INCONEL 625 is also highly resistant to chloride-contaminated media such as seawater, geothermal water, neutral salts and brines. Effective resistance to chloride-reducing stress corrosion cracking. Virtually non-corrosive in seawater and industrial gas environments, highly corrosion-resistant to seawater and salt solutions, also at elevated temperatures. No sensitivity during welding. Resistant to carbonization and oxidation in both static and cyclic environments, and resistant to corrosion by gases containing chlorine

Related Products

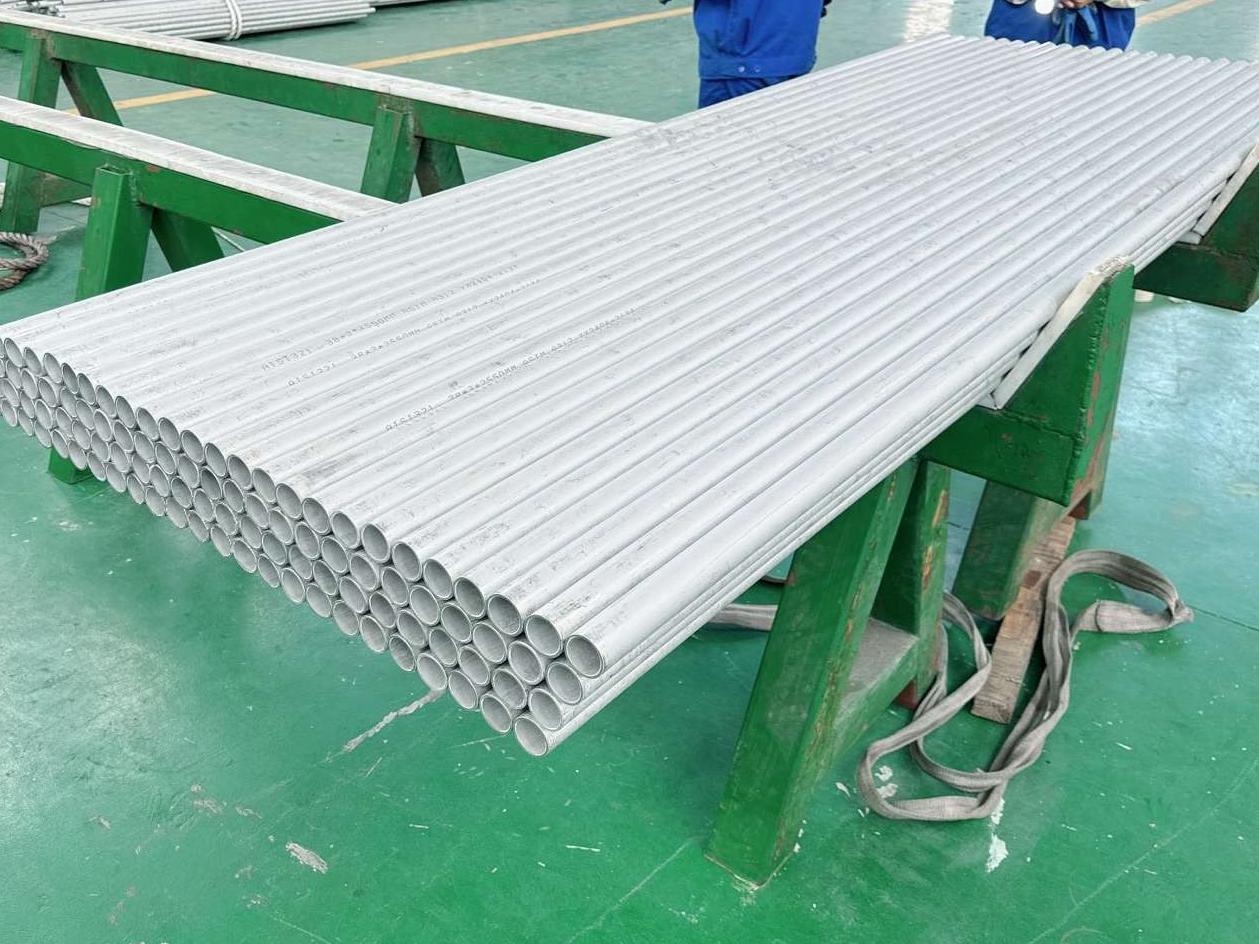

ASTM B444 / B829 Alloy 625 Nickel Alloy Seamless Tube

1. Grade : Alloy625 / N06625 , Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 , Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm 3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm 4 . Length : As cus......

Inc 625 / Inc 617 UNS N06625 / N06617 Bright Annealed Nickel Alloy Tube With High Strength

Alloy 625 Metallurgical structure: 625 is face-centered cubic lattice structure. Dissolve out the carbon granule and instability quaternary phase, then change it to stability Ni3 (Nb,Ti) trimetric lattice around 650℃ after a long time heat preservation. nickel-chromium content will strength the me......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語