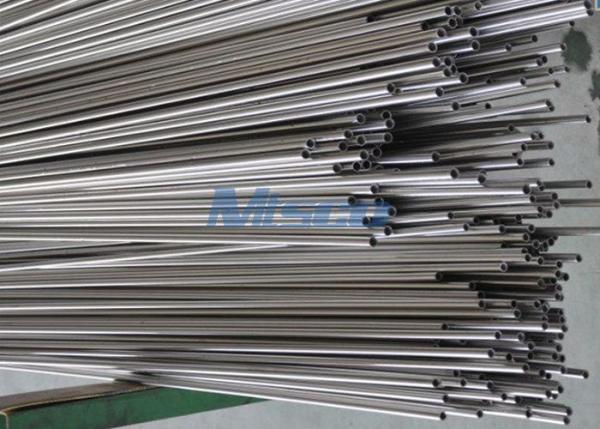

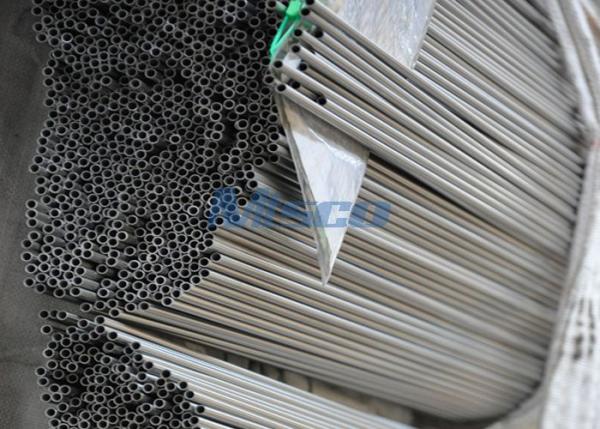

ASTM B167 Inconel 600 Nickel Alloy Seamless Pipe Tube

Why Inconel 600 pipe is so widely used?

Inconel 600 is a widely used nickel-chromium alloy with excellent high-temperature, corrosion and oxidation resistance, and is commonly used in nuclear reactor evaporators, petrochemical industry and heat treatment equipment.

Inconel 600 is the most widely used nickel-chromium alloy. Since the late 1950s and early 1960s, it has been used in nuclear reactor evaporators as a second-generation, high-strength, corrosion-resistant material, replacing the 18-8 Cr-Ni austenitic stainless steel. It has good high-temperature corrosion and oxidation resistance, excellent hot and cold working and welding process performance, satisfactory thermal strength and high plasticity below 700℃. It combines corrosion, heat and oxidation resistance with ease of processing and welding. Because of the simplicity of its composition and the ease of its production, its price is relatively low among all nickel-chromium compounds.

Inconel 600 seamless tubes have a wide range of properties, such as excellent resistance to stress corrosion cracking at both room and elevated temperatures, excellent resistance to corrosion by dry chlorine and hydrogen chloride gases, excellent mechanical properties at subzero, room, and elevated temperatures, and excellent creep fracture strength, and are recommended for use in operating environments above 700°C. Inconel 600 seamless tubes are also available in a wide range of materials, including stainless steel, stainless steel, stainless steel, stainless steel, stainless steel, and stainless steel.

Because of its excellent performance, Inconel600 seamless tubes are widely used in many fields, such as the erosive atmosphere of the thermocouple casing, vinyl chloride monomer production of chlorine, hydrogen chloride, oxidation and carbide corrosion, uranium oxidation conversion to hexafluoride hydrogen fluoride corrosion, corrosive alkali metal production and use of the field, in particular the use of sulfide environments, the use of chlorine method of titanium dioxide, organic or inorganic Chloride and fluoride production of chlorine and fluorine corrosion, nuclear reactors, heat treatment furnaces in the crankshaft bottles and components, especially in the carbonization and nitriding atmosphere, petrochemical production of catalytic regeneration in 700 ℃ above the application.

Inconel600 high temperature alloy seamless pipe also has good mechanical properties. Under different processing conditions, its mechanical properties will vary. For example, under annealed conditions, the alloy has a yield strength of 25,000 psi to 50,000 psi (172 MPa to 345 MPa) and an elongation between 35% and 55%. Tensile strengths of up to 220,000 psi (1,517 MPa) can be achieved for cold-worked materials. These excellent mechanical properties allow Inconel 600 high temperature alloy seamless tubes to adapt to a variety of complex working conditions. For example, in the aerospace field, the need to withstand enormous pressure and complex mechanical effects, Inconel600 high temperature alloy seamless pipe can meet these strict requirements.

Related Products

Alloy 600 / 601 UNS N06600/ N06601 Nickel Alloy Tube

1. Grade : Alloy625 / N06625 ,Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 ,Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm 3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm 4 . Length : As ......

ASTM B167 Alloy 600 / UNS N06600 Nickel Alloy Tube For High Temperature

1. Grade : Alloy 625 / N06625 , Alloy 600 / N06600 ,Alloy 601 / N06601 , Alloy 718 / N07718 , Alloy C276 / N10276 , Alloy 800 / N08000 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.6mm 3 . WT ( Wall Thickness ) : 0.5mm to 20mm 4 . Length : As customer......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語