ASTM B983 Alloy 718 / UNS N07718 Nickel Alloy Seamless Tube

SSNAT18

Price: From $60000-100000USD/TON

Material: Alloy 718, UNS N07718;

Get Quote

ASTM B983 Alloy 718 / UNS N07718 Nickel Alloy Seamless Tube

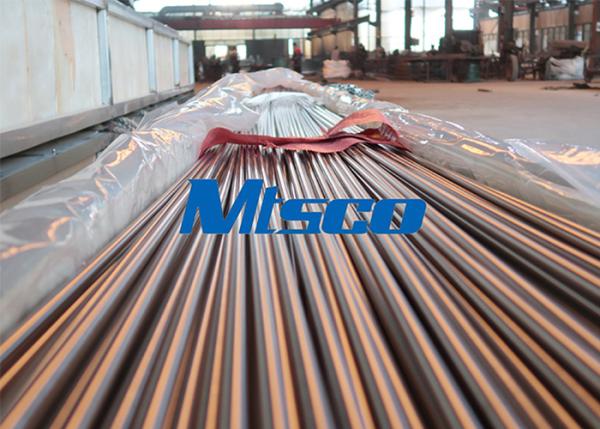

MTSCO is a Factory Complexes for industrial pipeline. MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . According to standard very strictly, nickel alloy tubes which produced by us always have correct OD and WT tolerance . Nickel alloy tubes have a very important position in thermocouple & cable industry .

Main market or alloy tube include Europe , Middle East , Southeast Asia , South America , etc . MTSCO has bright annealing alloy tube and pickling alloy tube . Compared these two kinds of tubes , bright annealed alloy tubes are more popular in the market . Because it has bright out and inner surface .

1. Material Grade: Alloy 718/UNS N07718, Alloy C276/UNS N10276, Alloy 800/UNS N08800, Alloy 825/UNS N08825, Alloy 400/UNS N04400; etc

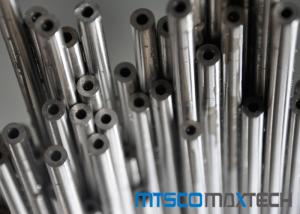

2. Outer Diameter: 3.18mm-101.60mm

Wall Thickness: 0.50mm-20.00mm

3. Length: Normally fixed length 6m, can as per customer's requirement

4. Standard: ASTM B163; ASTM B983; ASTM B444; ASTM B622 etc

5. Technology : Cold Drawn / Cold Rolled

Alloy 718 Chemical composition:

| % | Ni | Fe | Cr | Mo | C | Mn | Si | P | S | Co | Nb+Ta | Ti | Al | Cu | B |

| min | 50.0 | balance | 17.0 | 2.80 | - | - | - | - | - | - | 4.75 | 0.65 | 0.20 | - | - |

| max | 55.0 | 21.0 | 3.30 | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 1.00 | 5.50 | 1.15 | 0.80 | 0.30 | 0.006 |

Alloy 718 Physical Property:

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

| Alloy 718/N07718 | ≥550 | ≥965 | ≥30 | ≤363 |

| Alloy 800/N08800 | ≥210 | ≥500 | ≥35 | - |

| Alloy 800H/N08810 | ≥180 | ≥450 | ≥35 | - |

| Alloy 825/N08825 | ≥220 | ≥550 | ≥30 | ≤200 |

Features:

High Temperature Resistance: ASTM B983 Alloy 718 maintains strength and stability at elevated temperatures, making it suitable for high temperature processing and use.

Corrosion Resistance: This alloy has excellent corrosion resistance, including resistance to oxidation, corrosion and stress corrosion cracking.

Excellent Mechanical Properties: ASTM B983 Alloy 718 has good mechanical properties at both high and low temperatures, including high strength, good toughness and fatigue strength.

Weldability: It has good weldability and can be processed and joined by common welding processes.

Heat Treatability: ASTM B983 Alloy 718 can be heat treated to obtain different properties, such as solid solution treatment and aging treatment to regulate its hardness and strength.

Excellent machinability: The alloy is easily machined into a variety of shapes and sizes and is suitable for a wide range of processes.

Reliability: Due to its stable chemical composition and material properties, ASTM B983 Alloy 718 is reliable and durable in engineering applications.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

TP309s / 310s ASTM A213, Stainless Steel Bright Annealed Tube 6.35 * 0.71mm

Material Grade:TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , S31803 , S32750 , S32205 etc Outer Diameter:3.18-101.6mm Wall Thickness:0.5-20mm Length:Normally fixed length 6m , can as per customer’s requirement Standard:ASTM A213......

ASTM A213 8*1mm S31600 / 31603 Stainless Steel Bright Annealed Precision Tube

Bright Annealed Tube refers to a type of stainless steel tubing that undergoes a special bright annealing treatment during the manufacturing process. This treatment involves heating the tube to a high temperature, usually in a non-oxidising atmosphere, followed by rapid cooling. This process adjusts......

TP347 / 347H Stainless Steel Seamless Instrument Tubing With Bright Annealed Surface

Stainless steel seamless bright annealed tube’s final surface is polished and bright annealed . And the polished grade is includes 180# , 320# , 400# , 600# , 800# . According to standard very strictly , tubes which produced by us always have correct OD and WT tolerance . At instrument industry , b......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語