What is coiled tubing used for? Oil drilling, Heat exchanger, Industrial process

——Efficiency, Flexibility, and Reliability in Oil and Gas Industries

Discover the diverse applications of coiled tubing in oil drilling, heat exchangers, and industrial processes. With corrosion resistance, mechanical strength, and high adaptability, coiled tubing ensures efficient fluid transfer in extreme conditions.

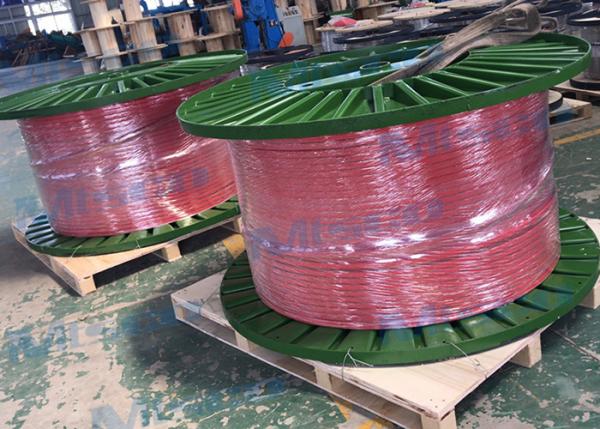

Coiled tubing has become a core component of the oil extraction and heat transfer equipment industries due to its efficiency and flexibility in industrial fluid transfer. These tubes are stored in a “coiled” form, significantly reducing transportation and operating space, while accommodating the rapid deployment of complex conditions. Coils are typically manufactured from 304 stainless steel, 316 stainless steel, duplex stainless steel (e.g. 2205 and 2507) and alloys 625 and 825.

The corrosion resistance, mechanical strength and temperature adaptability of the coils are directly dependent on the material technology, and MTSCO offers a full range of material solutions to cover more than 90% of industrial scenarios.

In terms of standards, coiled tubes follow international standards such as ASTM and API. These standards provide clear specifications for the production and testing of tubes to ensure the quality and performance of the products to meet the needs of different industrial sectors. According to the strict production process based on these standards, MTSCO provides coiled tubing products to ensure safe operation under high temperature and high pressure conditions.

Coiled tubing is widely used in the following areas due to its high strength, flexibility and corrosion resistance:

Oil drilling field:

Performing wellbore cleaning, acid fracturing in continuous tubing operations (CTU)

Intelligent tool string transportation in horizontal well sections

Control lines for subsea production systems on offshore platforms

Heat exchanger field:

Compact shell and tube heat exchanger core heat transfer unit

LNG gasifier spiral coil module

Reactor Jacketed Circulation System

Industrial process field:

Catalytic cracking unit regenerative flue gas waste heat recovery

Ethylene cracker emergency cooling boiler coil bundle

High pressure polymer transportation lines

Operation and maintenance are equally important during use. In order to ensure the long-term stability of the coil, the installation process should be precise and meticulous, avoiding excessive airflow impact and irregular bending. In addition, for the occasion of conveying corrosive fluids, the coiler should be made of suitable material to reduce the impact of material corrosion on service life. Regular inspection and maintenance can detect potential problems in time and ensure reliable operation of the pipeline.

As a professional control line manufacturer, MTSCO is committed to providing customers with high quality welded coils and encapsulated control lines. Our superior workmanship, strict standards and quality materials ensure that each coil can work stably under extreme conditions. Customers in the oil extraction and heat exchange equipment industries are welcome to contact us for professional consultation and detailed quotes, and we look forward to providing the best piping solutions for your projects.

Related Products

Nickel Capillary Tube Alloy 825/625 Downhle Welded Coiled Tube For Oilfield Services

An increasing number of projects in the oil service industry require the use of continuous lengths of stainless steel control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語