ASTM A312 Pipe, ASTM A312 TP 316L Stainless Steel Pipe

SSAPP17

Price: From $3900-4900USD/TON

Material: 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

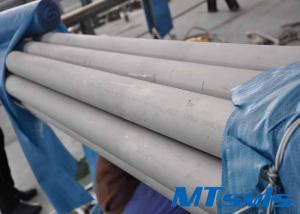

ASTM A312 TP 316L Stainless Steel Pipe

ASTM A312 TP316/TP316L Seamless pipes shall be made by a process that does not involve welding at any stage of production; ASTM A312 TP316/TP316L welded pipes shall be manufactured using an automatic welding process with no addition of filler metal during the welding process. The TP316/ TP316L pipe shall be heat treated by solution treatment, in which the pipe shall be heated and held for long enough period at a temperature no less than 1900°F [1040°C] so that all chromium carbides can be fully austenitized/ dissolved. Subsequent water cooling or rapid cooling by other means shall be conducted to ensure no precipitation of carbides at grain boundaries. Moreover, TP316L is less likely to precipitate chromium carbides compared to TP316 since their carbon content is low enough to reduce precipitation of intergranular carbides. This may result in limited sensitization hence benefit welding, flame cutting, and other hot-working operations.

There are wide range dimensions and sizes for ASTM A312 stainless steel pipe, sizes from 1/8 inch to 30 inch for outside diameter, Schedule 5 to Schedule 160 for wall thicKness, heavy wall pipe is available.

TP316/TP316L seamless pipes are highly resistance to chloride corrosion and therefore the 316l Stainless Steel Pipe resistant to pitting and crevice corrosion even under chloride rich environments. Stainless Steel 316L Pipe Seamless products can be used in boats, marine applications, sea water purification systems and in waste water management applications as well. There are different schedules of the pipes to accommodate different diameters and wall thicknesses. The Stainless Steel Pipe 316l Schedule 40 is a medium range pressure containment capacity whereas the Stainless Steel Pipe 316l Schedule 10s has comparatively smaller wall thickness. 316L Seamless Pipe Schedule 40 Pipe are one of the most used in the oil & gas industries. Electric resistant welded SS 316l Erw Pipe is stronger and can last longer. The advantage of 316l Welded Pipe is that it is easy to weld with or without filler materials.

Big Size Industrial Stainless Steel Seamless Pipe, ASTM A312 TP316L A&P Pipe

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test , Hydraulic test and so on . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd's , SGS , etc , also can be provided according to customers' requirements .

| Seamless pipes | ||||||||

| Pickling & Annealing | ||||||||

| Project | Standard | ASTM A269/A269M | ASTM A312/A312M | ASTM A213/A213M | ASTM A789/789M | ASTM A790/790M | ||

| Grade | TP304 | TP304 | TP304 | S32250 | S32250 | |||

| Size | NPS:1/8“-48”; SCH5S,10/10S,20,30,40/40S,60,80/80S,100,120,140,160,STD,XS,XXS | |||||||

| Length | According to customer's request, Max. 18Meters. | |||||||

| Chemical composition(According to the standard) | ||||||||

| Eg. TP304L(ASTM)/1.4306(DIN) | ||||||||

| C max | Si max | Mn max | P max | S max | Cr | Ni | N max | |

| TP304L | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | -- |

| 1.4306 | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 10.0-12.0 | 0.11 |

| Surface Finish | Annealed, Pickled etc | |||||||

| Packing | Bundles/plywood cases | |||||||

| Applications | For fluid & gas transport; structure & machining; petrochemical; environmental protection; electricity etc | |||||||

| Other standards | ASTM A270/270M |

1 . Our company has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers’ requirements .

Application

a) For fluid & gas transport

b) Structure & machining etc

Advantages

a) Advanced technology of cold draw machine

b) Advanced annealing machine

c) Better mechanical property

d) More precise dimension

e) Perfect inspection method and inspection equipment etc

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

EN10216-5 D4 / T3 Plain End Stainless Steel Seamless Pipe , 14 BWG , 18 BWG , 20 BWG

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

18Inch Stainless Steel Seamless Pipe With Pickled Surface

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

Big Size Industrial Stainless Steel Seamless Pipe, ASTM A312 TP316L A&P Pipe

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語