Bright or matte, what kind of surface do you want?

Due to the different application fields of industrial grade metal pipes, the required surface treatment processes are also different. Let's take a look at several common treatment processes

Pickling surface

Acid pickling is a method of using acid solution to remove oxide scale and rust on steel surface. It's a way to clean metal surfaces. It is usually carried out together with pre passing treatment.

Generally, the parts are immersed in the aqueous solution of sulfuric acid to remove the oxide film on the metal surface. After cleaning, the metal surface becomes silvery white, which can improve the corrosion resistance of stainless steel.

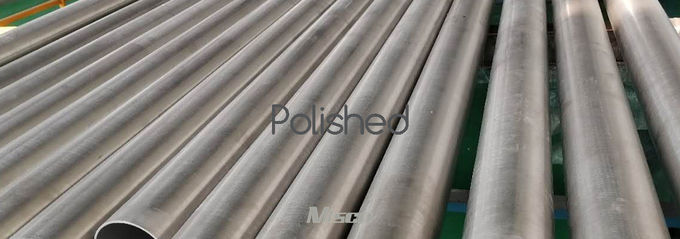

Polished surface

For some areas with higher requirements for stainless steel pipe surface, such as instrument, food, medical treatment, decoration and so on, it is necessary to polish the surface. A layer of black or gray oxide scale will be formed on the surface of stainless steel after hot processing, mechanical processing or storage for a certain time. The main components are Cr2O3, NiO and very insoluble FeO, Cr2O3. Their existence affects the appearance quality on the one hand, and also affects the product performance on the other. Therefore, appropriate measures should be taken to remove them. Stainless steel polishing can further improve the corrosion resistance and bright effect of stainless steel.

Sandblasted surface

Sandblasting is a process of cleaning and roughening the surface of substrate by the impact of high-speed sand flow. Because of the impact and cutting action of the abrasive on the surface of the workpiece, the surface of the workpiece gets a certain degree of cleanliness and different roughness, and the mechanical properties of the workpiece surface are improved. Therefore, the fatigue resistance of the workpiece is improved, the adhesion between the workpiece and the coating is increased, and the durability of the coating film is extended, It is also conducive to the leveling and decoration of coatings. After polishing, sandblasting can improve the smoothness of the workpiece, make the workpiece show uniform metal color, and make the appearance of the workpiece more beautiful

Shot peening surface

Shot peening is a kind of surface strengthening technology widely used in factories. It is a cold working technology that uses shot peening to bombard the surface of workpiece and implant residual compressive stress to improve the fatigue strength of workpiece. It is widely used to improve the mechanical strength, wear resistance, fatigue resistance and corrosion resistance of parts.

The advantages of shot peening are that it is not limited by the shape and position of the workpiece, and it is easy to operate. The types of shot peening include steel shot, cast iron shot, glass shot, ceramic shot, etc. In order to meet the higher and higher demand of quality from our clients, our factory spend huge cost to buy a new facility to make the pipe surface more shiny.

Many of our nickel alloy tubes will also be shot peened according to customer requirements, and the surface is very beautiful.

The above four kinds of surface treatment methods are the most frequently encountered in our production. They have their own advantages and disadvantages. As long as customers have different needs, we will help you choose the most cost-effective and suitable solution

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語