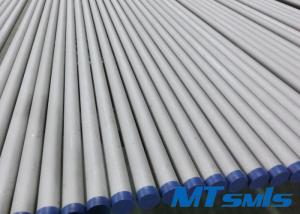

Cold Drawn Seamless Steel Tubing, CDS Stainless Tube

Cold Drawn Seamless Steel Tubing, CDS Stainless Tube

Precision tubing with enhanced surface quality and mechanical properties for mechanical and hydraulic applications.

Principle of Cold Drawn Process

Cold drawn technology is the process of heating seamless steel tubes to a certain temperature and then deforming the raw steel tube material to the desired shape by applying pressure to optimize the quality. A typical cold drawn process includes multiple cold drawn processes, quenching and tempering. Among them, the multiple cold drawn process is the most critical step. Through multiple processing, the inner and outer diameter dimensions are gradually reduced and the surface quality of the steel pipe is improved.

What is cold drawn seamless steel tubing?

Cold-drawn seamless steel tubing is a kind of precision cold-drawn seamless tubing used for mechanical structure and hydraulic equipment with high dimensional accuracy and good surface finish. Manufacturing mechanical structure or hydraulic equipment with seamless steel tube can greatly save machining man-hours, improve the material utilization rate, and at the same time help to improve product quality.

If you want to get a smaller size, better quality small diameter seamless steel tube, you must use a combination of cold rolling, cold drawing or cold drawing. Cold rolling is usually carried out in a two-roll mill, the tube is rolled in a ring-shaped hole pattern consisting of variable cross-section circular grooves and fixed cone head. Cold drawing is usually carried out on 0.5 to 100T single or double chain cold drawing machine.

High-quality carbon structural steel cold-drawn seamless pipe in addition to ensure that the chemical composition and mechanical properties, but also need to carry out hydraulic testing, crimping, flaring, flattening and other tests.

Application of Cold drawn process for seamless steel tube:

Cold drawn process is one of the important methods of seamless steel tube processing, which can effectively improve the mechanical properties and surface quality of steel tube. In the production of seamless steel tube, Cold drawn process is often used to achieve the following purposes:

Improve the surface quality of steel tube

After the seamless steel tube is cold drawn, the surface quality of the steel tube can be greatly improved, and the finish and precision will be greatly improved, because after multiple cold drawn process, the defects and oxidized skin on the surface of the steel tube will be eliminated, which will make the surface fairer and smoother.

Improve the mechanical properties of steel tube

Cold drawn technology can not only improve the surface quality of steel tube, but also improve its strength, plasticity, toughness and other mechanical properties. In the process of multiple processing, the fiber organization of the steel tube will be rearranged, thus improving the tensile strength, toughness, hardness and other performance indicators of the steel tube.

Optimization of steel tube size and shape

Cold drawn technology can realize the precise control of dimensional parameters such as inner diameter, outer diameter and wall thickness of steel tube by controlling the heating temperature and processing technology of steel tube. By adjusting the Cold drawn process, various shapes of steel pipe products can be obtained to meet the needs of different industries for steel tubes.

In a word, the seamless steel tubing cold drawn technology plays a vital role in the field of steel tube production, which can effectively improve the surface quality, mechanical properties and dimensional accuracy of steel tubes, and bring more high-quality steel tube materials to users from all walks of life.

Related Products

ASTM A268 TP410 Stainless Steel Seamless Pipe For Industry

TP410 is the basic and typical martensitic steel alloy. It has the high hardness with good ductility and a relatively limited corrosion-resistant capability.TP410 material does not have the nickel content and has a relatively low material cost. Mtsco supply TP410 Stainless Steel Seamless Pip......

ASTM A312 S30403 / 1.4306 Stainless Steel Big Size Seamless Pipe For Transportation

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語