What is Cold Rolled Steel Tubing? Why is Cold Rolled Steel Stronger?

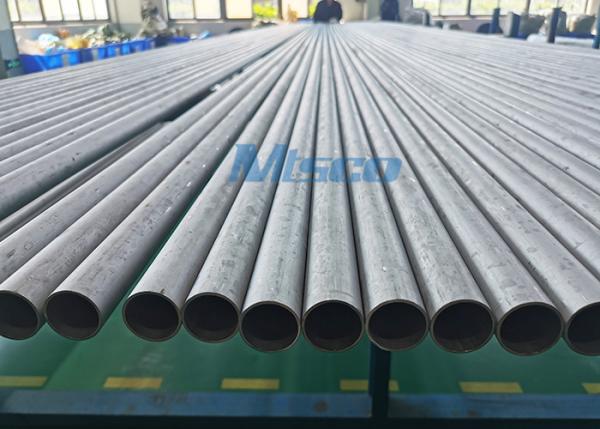

Cold Rolled Steel Tubing:

High-precision, strong, and reliable tubing widely used in automotive, aerospace, and hydraulic systems for superior performance.

What is Cold Rolled Steel Tubing?

Cold rolled steel is low-carbon steel rolled and finished at room temperature, below its recrystallization point. This permits better control over finished product shape, dimensions, and appearance.

Why cold rolling?

1、Increased Strength

2、Tighter Tolerances

3、Better Concentricity

4、Consistent Uniformity

5、Improved Surface Finish

In the industrial piping industry, cold rolled steel tubing is considered a premium choice due to its high precision and excellent mechanical properties. The cold rolling process improves the dimensional stability, finish and mechanical properties such as tensile strength and fatigue resistance of steel tubing by rolling the tubing several times at lower temperatures. Since there is no high-temperature heat treatment in the cold rolling process, cold rolled steel tubing typically has a finer grain structure, which enhances its mechanical properties and corrosion resistance.

Due to its high dimensional accuracy and surface quality, cold rolled steel tubing is widely used in automotive, aerospace, hydraulic systems, and various precision instruments and equipment. In these applications, any dimensional deviation or surface unevenness can affect performance, so cold rolled steel tubing is highly favored for its high precision and reliability.

In addition, cold rolled steel tubing is used in the manufacture of mechanical structural components such as bearings and gears, as well as in industrial fluid transportation systems such as oil, gas and water treatment. Their high strength and wear resistance also make them widely used in building structures and high-strength mechanical devices.

In summary, cold rolled steel tubing occupies an important position in the industrial piping industry due to its high precision, excellent mechanical properties and wide range of applications. Whether it is in the field of precision engineering or traditional industrial applications, cold rolled steel tubing can provide reliable and efficient solutions.

Related Products

ASTM A269 / ASME SA269 1.4306 / 1.4404 Stainless Steel Sanitary Tube With Cold Rolled

Bright annealed sanitary tube has very clean inner surface . MTSCO has our own high technology , when tubes have been produced they already have cleaned inner surface , even though we haven’t cleaned them . Of cause , we’ll do clean later . So when we finished clean process , the tubes are totally......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語