Difference between stainless steel and nickel alloy heat exchanger tubes

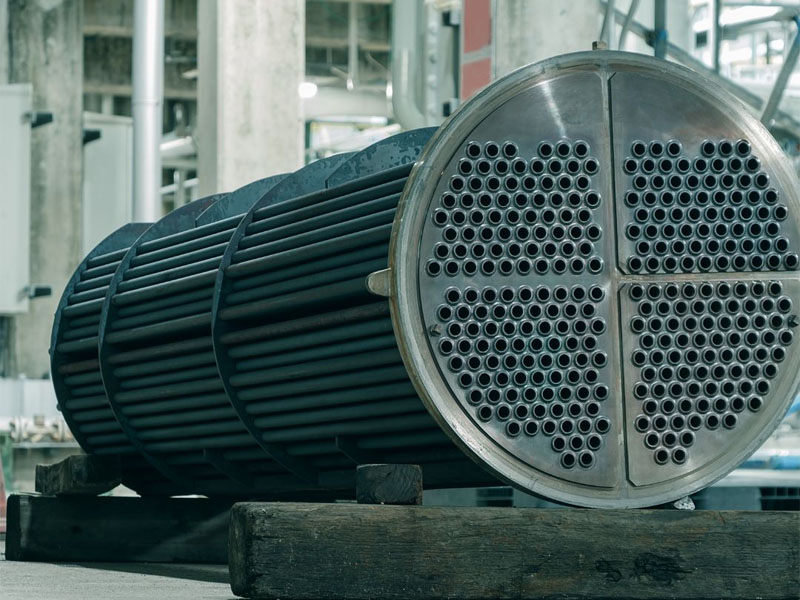

Stainless steel and nickel alloy heat exchanger tubes are two common materials used in industry, and they play a vital role in critical equipment such as heat exchangers and condensers. Understanding the difference between them is important in selecting the right material to ensure efficient and stable operation of the equipment.

Definition:

Stainless Steel Heat Exchanger Tubes: These heat exchanger tubes have iron, carbon and at least 10.5% chromium as their main components. The addition of chromium significantly improves the corrosion resistance of stainless steel. The material maintains good physical and chemical stability in many environments.

Nickel alloy heat exchanger tubes: Nickel alloy heat exchanger tubes contain a high percentage of nickel, as well as chromium, molybdenum and other alloying elements added, these elements together give the nickel alloy extraordinary corrosion resistance and high temperature resistance, suitable for more demanding working environment.

Difference:

Corrosion resistance: Although stainless steel has good corrosion resistance, nickel alloys have superior corrosion resistance in extreme environments, especially for seawater, high temperatures and some chemicals.

Temperature resistance: Nickel alloys are also far superior to stainless steel in terms of high temperature resistance, and can work stably for a long time at higher temperatures, while stainless steel's mechanical properties will be reduced at high temperatures.

Cost: Due to the special composition and manufacturing costs of nickel alloys, their price is usually higher than stainless steel, which makes stainless steel more popular in cost-sensitive applications.

Areas of application:

Stainless steel heat exchanger tubes: commonly used in food processing, pharmaceutical, construction, automotive and other industries, where good corrosion resistance and hygiene are usually required, but where working conditions are relatively mild.

Nickel alloy heat exchanger tubes: mainly used in petrochemical, aerospace, marine engineering and other high-end areas, the working environment in these areas is extremely harsh, requiring materials with very high corrosion resistance and high temperature resistance.

The choice of stainless steel or nickel alloy heat exchanger tubes needs to be decided according to the specific application environment and economic budget. Stainless steel tubes offer a cost-effective solution for most standard applications. Nickel alloy heat exchanger tubes, on the other hand, offer a reliable option for systems that need to operate under extreme conditions. Each material has its own unique properties and benefits, and the right choice ensures efficient operation and long-term stability of the heat transfer system.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語