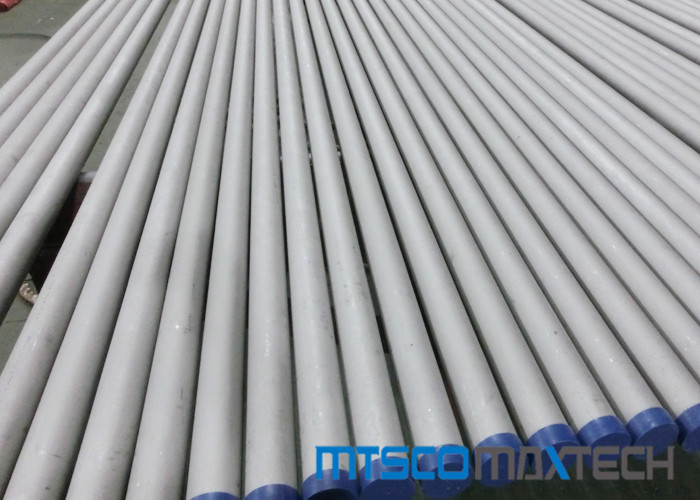

ASTM A790 S32750/2507 Duplex Steel Tube

SSDST06

Price: From $7000-10000USD/TON

Material: S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get Quote

ASTM A790 Tube,S32750/2507 Duplex Steel Tube,6096mm Length ISO 9001

ASTM A790 2507 duplex steel pickling tube are always purchased by the clients who need high corrosion tubes .

Compared to stainless steel tubes , duplex steel tubes have more higher corrosion ability . They can be used in sea industry .

Item | Description |

Material Grade | S32205 , S31803 , S32304 , S32750 , F51 , F53 , 2205 , 2507 etc |

Outer Diameter | 6.00mm - 48.00mm |

Wall Thickness | 0.71mm - 2.11mm |

Length | Normally fixed length 6m , can as per customer’s requirement |

Standard | ASTM A789 ; ASTM A790 ; EN 10216-5 ect . |

Process Method | Cold Drawn or Cold Rolled |

Super duplex Stainless Steel is a highly alloyed , good performance duplex steel with a pitting resistance . Super Duplex offers good resistance to pitting and crevice corrosion . It is suited for use in aggressive environments . It also has good resistance to stress corrosion cracking in chloride and sour environments . And it has good resistance to erosion corrosion and corrosion fatigue .

Super duplex stainless such as duplex is a mixed microstructure of austenite and ferrite which has improved strength over ferritic and austenitic steel grades . The main difference is super duplex has a higher molybdenum and chromium content which gives the material greater corrosion resistance .

Super duplex has the same benefits as its counterpart - it has lower production costs when compared with similar ferritic and austenitic grades and due to the materials increased tensile and yield strength , in many cases this gives the purchaser the welcomed option of purchasing smaller thicknesses without the need to compromise on quality and performance .

Application :

1 . Petroleum

2 . Chemical industry

3 . Instrument

4 . Industrial transportation

5 . Mechanical structure industry

6 . Need high corrosion ability pipe's industry , such as offshore industry etc

Test :

1 . NTD ( Ultrasonic test , Eddy Current test )

2 . Mechanical Test ( Tension Test , Flaring Test , Flattening Test , Hardness Test , Hydraulic test )

3 . Metal Test ( Metallographic Analysis , Impact Test-High/low temperature )

4 . Chemical Analysis ( Photoelectric Emission Spectroscopic )

| ASTM A790 Standard |

| 2205 / S32750 Elements |

| (C) Carbon , max : 0.030 |

| (Mn) Manganese , max : 1.20 |

| (P) Phosphorus , max : 0.035 |

| (S) Sulfur , max : 0.020 |

| (Si) Silicon , max : 0.80 |

| (Ni) Nickel : 6.0 - 8.0 |

| (Cr) Chromium : 24.0 - 26.0 |

| (Mo) Molybdenum : 3.0 - 5.0 |

| (Fe) Iron : -- |

| (Cu) Copper , max : 0.5 |

| (N) Nitrogen : 0.24 - 0.32 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

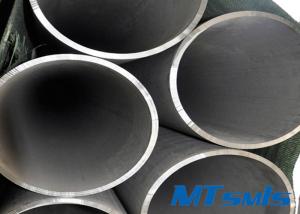

Get QuoteRelated Products: Seamless Pipe: Duplex Steel Seamless Pipe

UNS S31803 F51 Duplex Steel Pipe Cold Rolled Pipe 1.4410 Material

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

ASTM A789 / A790 2205 / 2507 Duplex Steel Seamless Pipe With Cold Rolled

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

DN400 ASTM A789 / ASME SA789 S32750 Duplex Steel Seamless Pipe For Transportation

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duple......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語