S31803 Seamless Tube Duplex Stainless Steel Tube

SSDST05

Price: From $5500-8000USD/TON

Material: S32205, S31803, 1.4462; S32760, 1.4501;

Get Quote

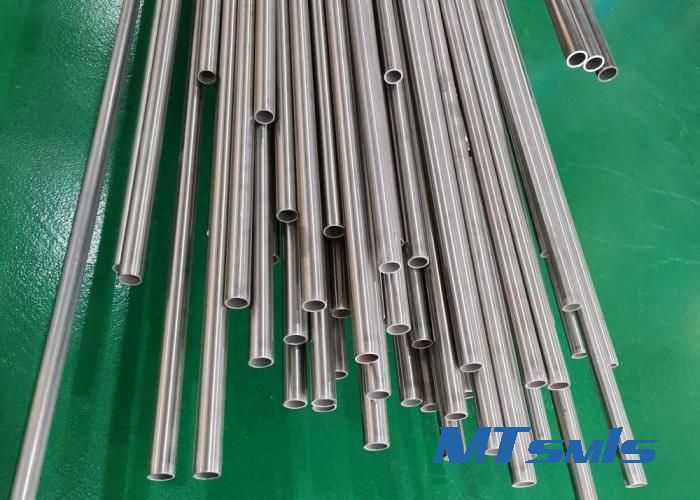

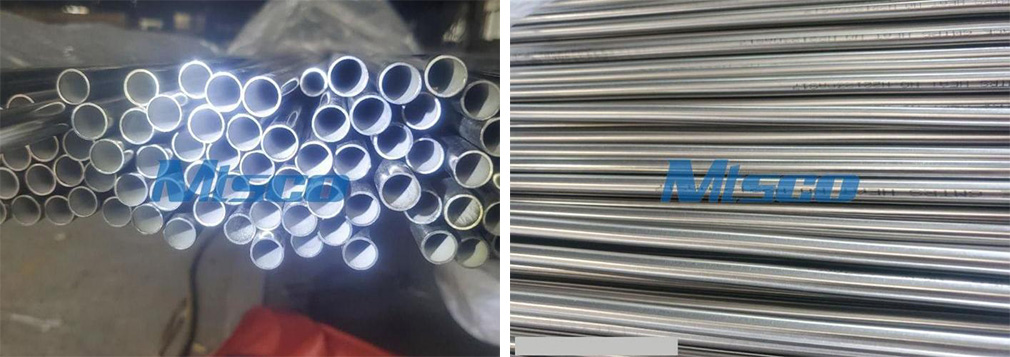

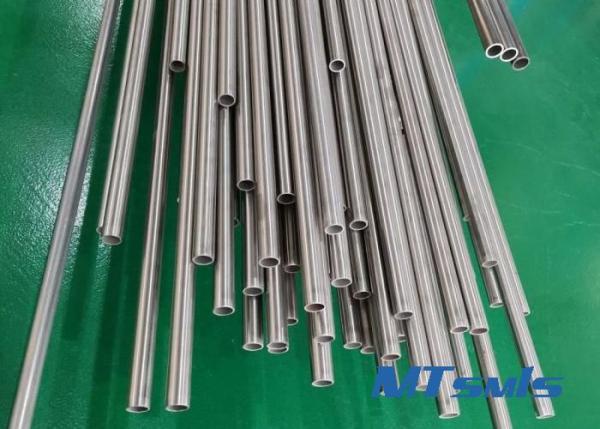

Seamless Duplex Stainless Steel Tube ASTM A789 S31803 / 2205 / 1.4462

Why Choose MTSCO S31803 Seamless Tube?

1. HUXIN PIPE - a seamless pipe supplier invested by MTSCO - is a highly reliable seamless steel tube manufacturer with 35 years of pipe making experience.

2. In addition to regular sizes, Huxin can also produce 18m and 25m extension tubes to provide diversified tube specifications.

3. A full range of production and inspection equipment is available, including cold rolling mills, annealing furnaces, pickling tanks, ultrasonic eddy current integration and physical and chemical laboratories.

4.The complete quality control process covers the factory technicians, while the full-time MTSCO quality inspectors control all the links before, during and after production.

5. We have ISO/PED/AD2000 certificates and other certificates.

Specifications of S31803 Seamless Tube:

Grade | Standard | Outside Diameter | 3.18mm-38mm |

S31803/2205 | ASTM-A789 | Wall Thickness | 0.5mm-3mm |

Length | ≤30m | ||

Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

Inspection | Appearance/ Dimensional test, PMI; | ||

Certificates | ISO/PED/AD2000/TS | ||

Package | End protection/ Woven bags/ Wooden cases |

Duplex Steel Tube VS Austenitic Tube:

Duplex steel seamless pipe and austenitic seamless pipe are two different types of stainless steel pipe, the main differences are as follows:

Chemical composition:

The chemical composition of austenitic stainless steel is mainly chromium and nickel, while duplex stainless steel adds more elements, such as molybdenum and nitrogen, to improve its corrosion resistance and mechanical properties.

Performance characteristics:

Austenitic stainless steel tube usually has good plasticity, toughness, weldability and corrosion resistance, and can maintain a stable organizational structure at both high and normal temperatures.

Duplex stainless steel tube is due to its special dual organization, with high strength and good corrosion resistance, especially the ability to resist stress corrosion cracking is stronger.

Application areas:

Austenitic stainless steel tubes are suitable for environments requiring good corrosion resistance and weldability, such as food processing, chemical and petroleum industries.

Duplex stainless steel tubes are more suitable for working conditions subject to high strength and corrosive environments, such as marine equipment, chemical and petrochemical equipment.

Chemical Composition of S31803 Seamless Tube:

UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

max | max | max | max | max | ||||||

S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

2205 | ||||||||||

S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

2507 | ||||||||||

S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

ASTM A789 Duplex Steel Seamless and Welded Tubing

ASTM A789 standard pipes are used in a wide range of applications. Due to its excellent corrosion resistance, it has a wide range of applications in chemical, petroleum, paper, pharmaceutical, food, metallurgical and other industries. Whether it is used to transport acid, alkali, salt and other corrosive media, or to withstand high temperatures, high pressure working environment, ASTM A789 standard pipe can withstand the pressure, to complete the task.

The advantage of seamless and welded duplex steel pipe is that it does not require welding, which ensures the integrity of the pipe and greatly reduces the risk of breakage caused by welding. Welded pipe, on the other hand, has won industry acclaim for its excellent weldability, allowing ASTM A789 standard pipe to perform well in applications that require welding.

Overall, ASTM A789 seamless and welded duplex tubes have become an indispensable part of the industry due to their excellent performance and wide range of applications.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

Seamless Duplex Stainless Steel Tube ASTM A789 S31803 / 2205 / 1.4462

A special type of stainless steel tube, the Duplex Seamless tube, comprises two crystalline structures: austenite and ferrite. This tube offers exceptional corrosion resistance and high strength, merging the superior corrosion resistance of austenitic stainless steel with the robust strength of ferr......

SAF2507 Seamless Duplex Steel Tube 1 Inch Sch80 33.4 x 4.55 mm

Material Grade: S32205 , S31803 , S32304 , S32750 , F51 , F53 , 2205 , 2507 etc Outer Diameter:3.18mm - 101.60mm Wall Thickness: 0.50mm - 20.00mm Length: Normally fixed length 6m , can as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5 etc. Process Method: Cold Drawn......

Duplex Stainless Steel Seamless Tube S31803 / S32205 / S32750

MTSCO has 26 cold-drawing production lines. And the annual production capacity is 5000 tons, the annual GDP is more than 30 million USD. 1 . Seamless tube : small diameter seamless overlength coiled tubing , bright annealed tube , inside and outside polished tube , heat exchanger tube , U-bent ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語