How to identify inferior stainless steel welded pipe?

1. Folding

Fake and inferior welded stainless steel pipes are easy to fold. Folding is a variety of fold lines formed on the surface of stainless steel pipes. This defect often runs through the longitudinal direction of the whole product.

The reason for folding is that fake and inferior manufacturers pursue high efficiency too much, and the reduction is too large, resulting in the formation of ears in the pipe, which will be folded in the next rolling. The folded products will crack after bending, and the strength of stainless steel pipes will be significantly reduced.

The appearance of fake and inferior welded stainless steel pipes will have pitting. Pitted surface is a kind of irregular and uneven defect on the surface of stainless steel due to serious wear of rolling groove.

2. Scarring

The surface of fake and inferior stainless steel welded pipe is easy to scar, which is mainly caused by two reasons. One is that the material of inferior stainless steel welded pipe is uneven and there are many impurities. The other is that the environmental sanitation equipment of the manufacturer of fake and inferior stainless steel welded pipe is simple and easy to stick to the steel. These impurities are easy to form scabs after biting into the roll.

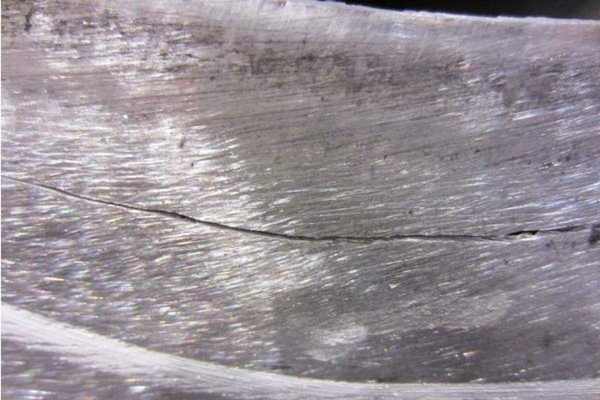

3. Cracks

It is also easy to form cracks on the surface of fake stainless steel welded pipes, because the billets are adobe, which has a lot of air holes. The adobe is subject to thermal stress during the cooling process, forming cracks, and will have cracks after rolling.

4. Dull surface

The surface of inferior stainless steel welded pipe has no metallic luster, which will show a light red color or a color similar to pig iron, and it is easy to be scratched. Because the production equipment of the manufacturer of inferior stainless steel welded pipe is simple, it is easy to form burrs, scratch the steel surface, and deep scratches will weaken the strength of the stainless steel pipe.

5. Specification is not up to standard

The negative tolerance of low-quality stainless steel welded pipe usually exceeds the specification, contains many impurities, the density of stainless steel pipe material is low, and the size out of tolerance is also serious

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語