Why nickel alloy is more expensive?

Nickel is a ferromagnetic metal element with excellent properties such as corrosion resistance, high temperature resistance, oxidation resistance and good ductility. It is widely used in metallurgy, chemical industry, aerospace and other fields. It is an important raw material for the preparation of stainless steel, high-temperature alloys, power batteries and other materials. It is a key strategic metal resource. The world's nickel resources are mainly distributed in Indonesia, Australia, Brazil and Russia, while China's nickel reserves account for less than 3%, which is a typical "low nickel" country.

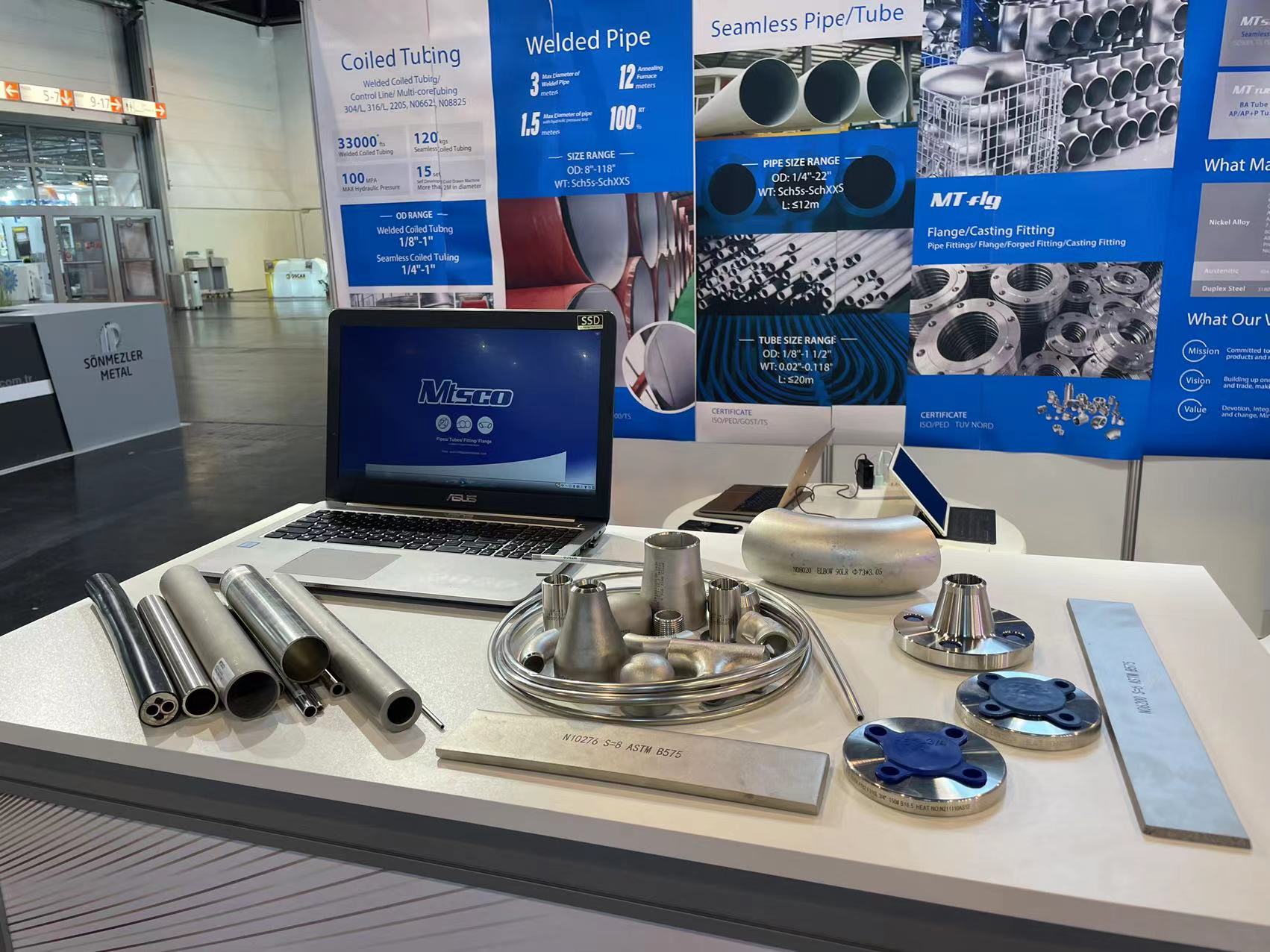

Nickel alloy is also MTSCO main product. We can provide the following materials:

Alloy B/ B2/ C276/ C22/ C4......

Alloy 600/ 601/ 625/ 718

Alloy 800/ 800H/ 800HT/ 825......

Alloy 400/ K500......

Nickel 200/ 201......

This week, We are at Tube Dusseldorf, waiting for you at the booth.4E10-2. Welcome to consult and reference samples

Nickel and nickel alloy applications

Nickel and nickel alloys are a kind of important strategic materials, which have excellent properties, such as excellent corrosion resistance, thermal strength, excellent process performance, and special electromagnetic, memory and other functional properties. Their processing materials are a kind of high value-added products, and are one of the hot metals studied at home and abroad.

Nickel alloys can be divided into high-temperature alloys, corrosion-resistant alloys, memory alloys, wear-resistant alloys and precision alloys. Nickel alloys have excellent corrosion resistance, high temperature strength and oxidation resistance. Some special alloys also have special functions such as memory and excellent electromagnetism. Therefore, they are widely used in military aerospace, aerospace navigation, electrical and electronic, petrochemical, new energy and other industrial fields.

Characteristics of nickel alloy

01.Excellent performance

It can maintain high strength at high temperature, and has excellent mechanical properties such as creep resistance, fatigue resistance, oxidation resistance, corrosion resistance, good plasticity and weldability.

02. Complex alloy addition

More than ten alloying elements are often added to nickel base alloys to improve corrosion resistance in different environments; And solid solution strengthening or precipitation strengthening.

03. Extremely harsh working environment

Nickel base alloys are widely used in a variety of severe service conditions, such as high temperature and high pressure parts of space flight engine gas chambers, structural parts of nuclear, petroleum and marine industries, corrosion-resistant pipelines, etc.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語