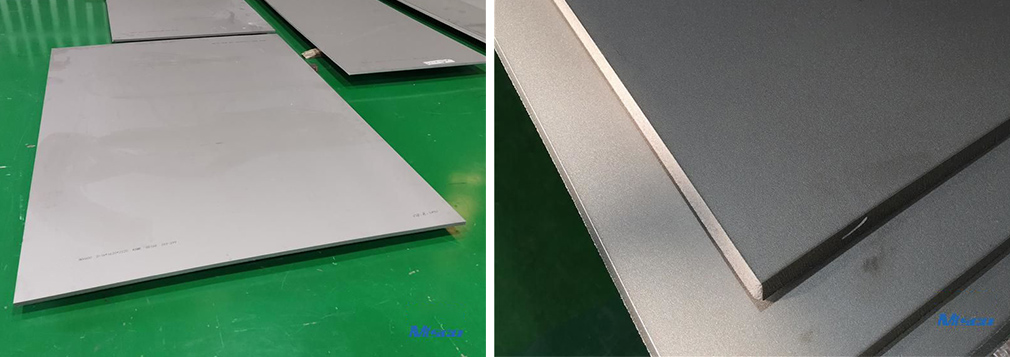

Monel 400 Sheet, UNS N04400 Nickel Alloy 400 Sheet/Plate

Specifications of Nickel Alloy 400 Plate:

| Sheet | Plate | Strip | |

| Thickness | <6mm | ≥6mm | 0.15mm-3mm |

| Width | ≤1200mm | ≤2800mm | ≤1000mm |

| Length | ≤3000mm | ≤8000mm | As customer’s requirement |

Chemical composition of Nickel Alloy 400:

| % | Ni | Cu | Fe | C | Mn | Si | S |

| min | 63 | 28 | |||||

| max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

The Properties and Applications of Nickel Alloy 400:

In terms of features, Monel 400 stands out for its outstanding resistance to corrosion from various reducing media, including sulfuric and hydrochloric acids. Its corrosion resistance to oxidizing media exceeds that of higher copper alloys. Monel 400 effectively combats pitting and stress corrosion cracking in most fresh and industrial waters. While it exhibits good resistance in flowing seawater, stagnant conditions may induce pitting and crevice corrosion. Remarkably, Monel 400 is likely the most resistant among engineering alloys to hydrofluoric acid in all concentrations up to the boiling point. Noteworthy for its toughness, this alloy remains non-brittle even at cryogenic temperatures and can be work-hardened.

In terms of applications, Monel 400 finds utility in a range of settings, including chemical process equipment, crude oil stills, tanks for gasoline and fresh water, marine engineering equipment, as well as valves, pumps, and fasteners. Its versatility makes it a preferred material in various industries where resistance to corrosion and robustness are critical factors.

Application Areas of Nickel Plate:

Aerospace: Nickel plate is widely used in aerospace and aviation because of its excellent properties such as high strength, high temperature and corrosion resistance. For example, precision parts such as aircraft engines and turbine blades need to use high-quality nickel plate as material.

Chemical: In the chemical industry, nickel plate is often used in the manufacture of components such as hydrogenation reaction equipment, chemical storage tanks and pipelines because of its very excellent corrosion resistance.

Electronics: in the electronics industry, nickel plate is mainly used in the manufacture of electronic components, such as solid-state electronic devices, capacitors, inductors, etc. For the manufacture of printed circuit boards, nickel plate is mainly used in the manufacture of electronic components. For the manufacture of printed circuit boards, nickel plate can be used as a cladding material for conductive patterns to improve its corrosion resistance and conductivity.

Food processing: Because stainless steel has good food hygiene, and stainless steel nickel plate has good toughness, wear resistance and corrosion resistance, so it is often used in the production of food processing machines and equipment.

The production process of nickel plate is mainly divided into ingot preparation, rolling, heat treatment and surface treatment steps. Among them, rolling is the core link of nickel plate production. The processing of nickel plate includes hot rolling, cold rolling and extrusion, etc. Although these processes are different, the final effect is to make the metal plate with precise dimensions and the required physical properties and surface finish.

Quality Control of MTSCO Nickel Alloy Plate:

Raw Material Quality Assurance

Stringent warranty and PMI checks are conducted on our raw materials, procured from esteemed steel mills like Baosteel and Tsingshan, ensuring their superior quality. Compliance with material specifications is guaranteed through rigorous PMI checks and other meticulous inspections.

Supervised Production Process

Every phase of our plate manufacturing process, including cold rolling, cold drawing, undergoes meticulous oversight. Skilled engineers, equipped with advanced tools, supervise each step, capturing detailed records through photography. Process cards ensure precision and traceability throughout production.

Quality Assurance Prior to Shipment

Our dedicated QC team conducts comprehensive inspections covering appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are performed. Additionally, we invite third-party evaluations (SGS, TUV, BV) and guarantee secure packaging and container reinforcement to maintain product integrity during transportation.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

ASTM B564 Alloy 600 / N06600 Nickel Alloy Socket Welding Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisf......

F316L / 316 Stainless Steel Flange , PLRF ASTM A182 PN16 DN150 Flange

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

DIN2628 1.4404 Stainless Steel Welding Neck Flange

Material Grade: WP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etc Size: 1/2 to 48 Sch 5S to XXS Standard: DIN2628 etc . Process Method: Forged / Casting 1 . Commodity : Welding Ne......

ASTM B670 Alloy 718 / N07718 Nickel Allloy Sheet / Strip

1. Grade :Alloy 718 / N07718, Alloy C276/N10276, Alloy C-4/ UNS N06455,Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B333; ASTM B575; ASTM B16......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語