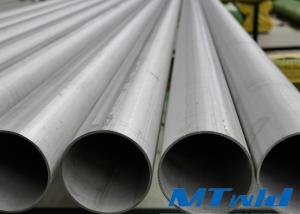

ASTM A928 UNS S31803 Duplex Stainless Steel EFW Weld Pipe

SSDWP10

Material: S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get Quote

ASTM A928 UNS S31803 Duplex Stainless Steel EFW Weld Pipe

ASTM A928 is an international standard that specifies the production and performance requirements for duplex stainless steel welded pipes.

Key points of ASTM A928 standard:

Applicable duplex stainless steel materials

UNS S31803/S32205 (2205): This is the most common duplex stainless steel, with approximately 22% chromium, 5-6% nickel, and 2-3% molybdenum, giving it excellent resistance to pitting and crevice corrosion.

UNS S32750 (2507): Super duplex stainless steel with higher chromium, nickel, and molybdenum content, possessing stronger corrosion resistance and high strength performance.

UNS S32760: Similar to S32750, it has higher resistance to seawater corrosion and chloride stress corrosion.

Welding process: ASTM A928 is applicable to welded pipes manufactured through automatic welding processes such as arc welding or resistance welding. These pipelines undergo non-destructive testing and heat treatment to ensure the quality of welded joints and material consistency.

Mechanical properties: Dual phase stainless steel material combines the characteristics of austenite and ferrite, with high strength and excellent ductility. Compared to traditional austenitic stainless steel, duplex stainless steel can withstand higher pressure at the same thickness and has reduced brittleness at low temperatures.

Specifications :

| DN | NPS(Inch) | D(mm) | SCH5S | SCH10S | SCH40S | STD | SCH40 | SCH80 | XS | SCH80S | SCH160 | XXS |

| 50 | 2 | 60.3 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 |

| 65 | 2 1/2 | 73 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 |

| 90 | 3 1/2 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | - | - |

| 100 | 4 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 13.49 | 17.12 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | 6.55 | 6.55 | 6.55 | 9.53 | 9.53 | 9.53 | 15.88 | 19.05 |

| 150 | 6 | 168.3 | 2.77 | 3.4 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 18.26 | 21.95 |

| 200 | 8 | 219.1 | 2.77 | 3.76 | 8.18 | 8.18 | 8.18 | 12.7 | 12.7 | 12.7 | 23.01 | 22.23 |

| 250 | 10 | 273.1 | 3.4 | 4.19 | 9.27 | 9.27 | 9.27 | 15.09 | 12.7 | 12.7 | 28.58 | 25.4 |

Duplex Steel 31803 Chemical Composition

Grade | C | Mn | Si | P | S | Cr | Ni | Mo | N | Fe |

S31803 | 0.030 max. | 2.00 max. | 1.00 max. | 0.030 max. | 0.020 max. | 22.0 – 23.0 | 4.50 – 6.50 | 3.0 – 3.5 | 0.14 – 0.20 | 63.72 min. |

Why Choose MTSCO Welded Pipe?

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Duplex Steel Welded Pipe

S32750 F53 1.4410 Duplex Steel Big Size Annealed & Pickled Welded Pipe

ASTM A269 - 10 : Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service ASTM A312 / A312M - 12 : Standard Specification for Seamless , Welded , and Heavily Cold Worked Austenitic Stainless Steel Pipes ASTM A789 / A789M - 10a : Standard Specification ......

S32750 / S32760 1.4410 Duplex Stainless Steel Annealed & Pickled Welded Pipe

Outer Diameter: 10.3mm-1219mm Wall Thickness: 1.24mm-59.54mm Length: Normally fixed length 6m , can as per customer's requirement Standard: ASTM A312 ; ASTM A358 ; ASTM A789 ; ASTM A790 etc . Process Method: ERW , EFW etc MTSCO has been dedicated to producing welded pipe and tube since 2003......

S32750 / SAF2507 DN300 Big Size Duplex Steel ERW / EFW Welded Pipe

ASTM A928 is an international standard that specifies the production and performance requirements for duplex stainless steel welded pipes. Welding process: ASTM A928 is applicable to welded pipes manufactured through automatic welding processes such as arc welding or resistance welding. These pip......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語