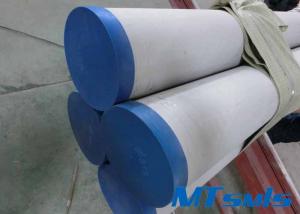

Schedule 40S Pipe, Stainless Steel SCH 40S Pipe

Stainless Steel SCH 40S Pipe:

High-strength, corrosion-resistant, and precision tubing, ideal for use in petroleum, chemical, and heating industries.

Stainless steel pipe is characterized by a thicker wall thickness that is more economical and practical, lower precision, and the need for offline inspection and shaping. Its corrosion resistance depends on chromium, nickel, molybdenum and other alloying elements, chromium content of 12% will form a self-passivation film to prevent further corrosion. The pipe is resistant to a wide range of corrosive media and is widely used in the petroleum, chemical, medical, food, machinery and other industries with the advantages of light weight and high strength, and is also used in the manufacture of mechanical parts and conventional weapons.

Manufacturing process of Stainless Steel SCH 40S Pipe:

The manufacturing process of Stainless Steel SCH 40S Pipe mainly includes material preparation, roll forming, welding, annealing treatment and other links. In the manufacturing process, it is necessary to strictly control the material composition, heating temperature, cooling speed and other parameters to ensure that the chemical composition of the product is uniform, fine grain, uniform and dense internal organization. The rationality and stability of the welding process is directly related to the quality and service life of the pipe, while the annealing treatment can eliminate welding stress and improve the mechanical properties of the pipe.

Stainless Steel SCH 40S Pipe has the following characteristics:

High strength: Stainless Steel SCH 40S Pipe has a relatively large wall thickness and is able to withstand high pressure and mechanical loads.

Strong corrosion resistance: steel pipes are usually made of high-quality steel, capable of long-term stable operation in harsh environments.

High dimensional accuracy: the production process of Stainless Steel SCH 40S Pipe is more precise, with high dimensional accuracy, suitable for occasions with strict dimensional requirements.

Widely used: widely used in petroleum, chemical, heating, ships and other fields, used to transport a variety of media such as liquids, gases and solids.

Related Products

DN200 Sch40 S31603 / S30403 Austenitic Annealed & Pickled Stainless Steel Pipe

Annealed pickled pipes are stainless steel pipes treated through annealing and pickling processes. These methods enhance ductility, reduce internal stresses, and create a clean, smooth surface. Ideal for chemical, food, and pharmaceutical industries, these pipes offer improved corrosion resistance a......

12 Inch Sch40 TP347 / 347H Austenitic Stainless Steel Pipe With Annealed & Pickled Surface

MTSCO is a leading manufacturer who is specialized in seamless stainless steel pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Seamless stainless steel pipes final surface are p......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語