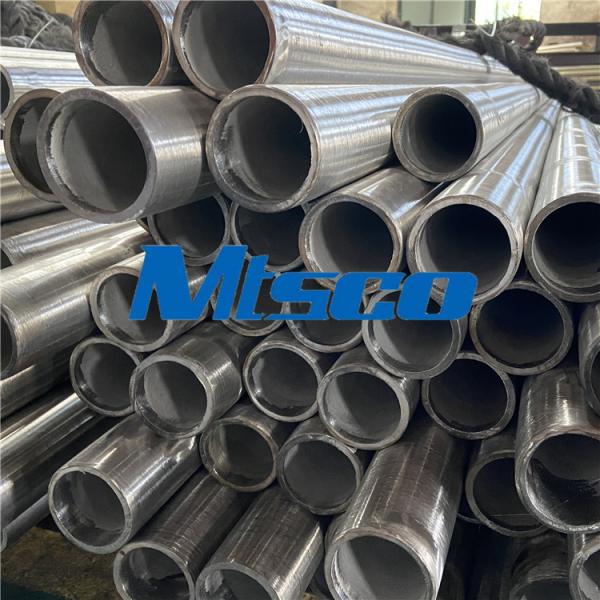

Seamless Stainless Steel Pipe & Tubing, Benefits, Applications

Seamless Stainless Steel Pipe & Tubing, corrosion-resistant tubing ideal for critical applications in medical, automotive, construction, and oil and gas industries.

What is a seamless stainless steel tube?

Stainless Steel Seamless Tube is a long piece of steel with a hollow cross-section and no seams around it. The thicker the wall thickness of the product, the more economical and practical it is, and the thinner the wall thickness, the processing cost will rise substantially.

The process of the product determines its limited performance, general seamless steel pipe precision is low: wall thickness is not uniform, low brightness of the inner appearance of the tube, high cost of sizing, and the inner appearance of the pockmarks, black spots are not easy to remove; its detection and shaping must be processed offline. Therefore, it reflects its superiority in high-pressure, high-strength, mechanical structure materials.

Seamless Stainless Steel Tubing Benefits:

Seamless Stainless Steel Tubing can be manufactured without welding. It is made by extruding or perforating a solid stainless steel billet into a tube.

Purity: this pipe is known for its purity and has no weld lines, thus reducing the risk of contamination.

Strength and corrosion resistance: seamless tubing is strong and corrosion resistant as there are no weld lines.

Ideal for critical applications: due to its resistance to high pressure and purity, this type of pipe is ideal for critical applications in the pharmaceutical, aerospace or oil and gas industries.

Applications for Seamless Stainless Steel Tubing:

Seamless Stainless Steel Tubing are more than just parts, they are versatile solutions for many industries. Known for their durability and corrosion resistance, these tubes are the preferred choice for applications that require precision engineering and creative architectural design.

Medical Device Industry

Seamless Stainless Steel Tubing plays a vital role in the medical industry and is the backbone of a wide range of medical devices and instruments. From disposable and reusable medical devices to orthopedic and ophthalmic tools, stainless steel tubing is a fundamental component in the production of these essential medical supplies.

Precision engineering

In applications where precision is critical, tube diameters are vital to ensure a seamless fit to machinery and equipment.

Construction

Seamless Stainless Steel Tubing plays a vital role in the construction industry and is used in a wide range of applications including building structures, bridges and infrastructure. Their adaptability in extreme weather conditions, corrosion resistance and ability to withstand heavy loads make them ideal for such applications. Stainless steel tubes ensure the safety and longevity of buildings, ensuring that they stand the test of time.

Automotive industry

In the automotive industry, Seamless Stainless Steel Tubing is used in a wide range of applications, mainly in exhaust systems. The high temperature resistance of stainless steel ensures that these tubes can withstand the heat generated by automobile engines. Additionally, the corrosion resistance of stainless steel allows them to withstand harsh weather conditions and road salt, making them a durable option for exhaust systems.

Food and beverage industry

Stainless steel tubes are an essential material for the food and beverage industry due to their hygienic properties and corrosion resistance. They are commonly used in food processing equipment, dairies, breweries and beverage production facilities. Stainless steel tubes prevent contamination, maintain product quality and ensure compliance with stringent hygiene standards.

Oil and gas industry

Stainless steel tubes are essential in the oil and gas industry, especially for drilling, extraction and transportation. They are used in pipelines, refineries, offshore platforms and petrochemical plants. Stainless steel's resistance to corrosion and high-pressure environments makes it an ideal material for these applications, ensuring safe and efficient oil and gas transportation.

Related Products

TP304 / 304L Precision Stainless Steel Seamless Tube, ASTM A269 / ASME SA269

MTSCO has the most advanced technology — The floating plug drawing technology which are used in Korea , and equipped with the most environmentally process — Bright annealing process . So our bright annealed precision tube produce technology make us can produce 300 tons high precision tubes every m......

10 / 12 / 14SWG Precision Stainless Steel Seamless Tube With Cold Rolled For Medical Industry

MTSCO has the most advanced technology — The floating plug drawing technology which are used in Korea , and equipped with the most environmentally process — Bright annealing process . So our bright annealed precision tube produce technology make us can produce 300 tons high precision tubes every m......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語