Stainless Steel Flanges Pipe Fittings 300 Series Raw Material ISO 9001 / PED

MTSSPF12

Material: 316L, 1.4401, 1.4404, 1.4435; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 304, 1.4301, X5CrNi18-10; 309/309S/309H, 1.4833; 310/310S/310H,1.4845;

Get Quote

Stainless Steel Flanges Pipe Fittings 300 Series Raw Material ISO 9001 / PED

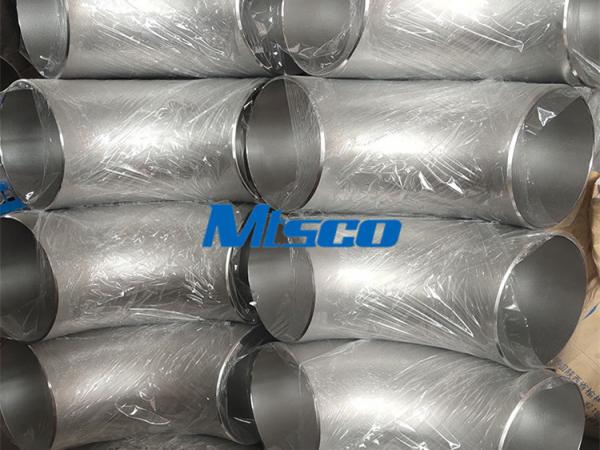

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement .

| 1 . Commodity : Welding Neck , Blind , Slip On , Lap Joint , Socket Weld , Threaded , Spectacle Blind , etc |

| 2 . Surfacing : RF , FF , RTJ |

| 3 . Materials : Stainless Steel , Duplex Steel , etc |

| 4 . Standards : ANSI B16.5 , ANSI B 16.47 |

| 5 . Tolerances : according to the specification or customer’s request and drawings |

| 6 . Applications : Pipe connection , Piping project construction etc |

| 7 . Pressure class : 150 - 2500lbs |

Item | Description | |

Basic Information | Material Grade | WP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etc |

Size | 1/2" to 48" Sch 5S to XXS | |

Standard | ASTM A403 etc . | |

Process Method | Forged / Casting | |

Industry & Advantage | Application | a) Connect pipes |

Advantage | a) High technology ; good surface ; high quality etc | |

Terms & Conditions | Price Item | FOB , CFR , CIF or as negotiation |

Payment | T / T , LC or as negotiation | |

Delivery Time | 30 working days after received your deposit ( Normally according to the order quantity ) | |

Package | Plywood case or as per customer’s requirement | |

Quality Requirement | Mill Test Certificate will be supplied with shipment , Third Part Inspection is acceptable | |

Quality | Test | 100% PMI test ; Size test etc |

Market | Main Market | Europe , Middle East , Southeast Asia , South America . Etc |

Chemical Composition :

ASTM/UNS | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cr | Ni | Mo | Ti |

TP304/S30400 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 |

|

|

TP304L/S30403 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-13.0 |

|

|

TP304H/S30409 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 |

|

|

TP316/S31600 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

|

TP316L/S31603 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

|

TP316Ti/S31635 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

TP321/S32100 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 |

| 0.7>5x(C+N) |

TP317L/S31703 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

|

TP347H/S34709 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 |

|

|

TP309S/S30908 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | 0.75 |

|

TP310S/S31008 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | 0.75 |

|

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Pipe Fittings: Butt Welded Pipe Fittings

Nickel Alloy 825, UNS N08825, 2.4858, Incoloy 825 Pipe Fittings, Tees, Elbows, Reducers

Nickel Alloy 825 fittings, including tees, elbows, and reducers. This alloy offers excellent corrosion resistance in various environments, such as reducing and oxidizing acids, seawater, and brines. It has good mechanical properties at both high and low temperatures. Whether in chemical processing, ......

ASTM A403 WP304L / 316L Stainless Steel 90 Degree Elbow Pipe Fitting

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

ASME / ANSI B16.9 F51 / F53 S31803 / S32750 Duplex Steel Equal / Reducer Tee Pipe Fitting

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語