The operation and application of butt welding

Butt resistance welding (hereinafter referred to as butt welding) is a kind of resistance welding method that uses resistance heat to weld two workpiece together along the whole end face at the same time. Elbow, butt welding flange and other stainless steel pipe fittings are mostly used butt welding processing.

Butt welding is divided into resistance butt welding and flash butt welding two.

Butt welding is a method of pressing the end faces of two workpieces tightly from beginning to end, heating them to the plastic state by using resistance heat, and then quickly applying the push forging pressure (or maintaining the welding pressure only without the push forging pressure) to complete the welding.

Flash butt welding is a method to assemble two welding parts into butt joint by placing them relative to each other, turn on the power and make the end face gradually close to reach local contact, use resistance heat to heat these contacts (to generate flash), quickly apply the overhead forging force, and get the permanent joint.

Its application scope can be summarized as follows:

(1) Connection length of workpiece

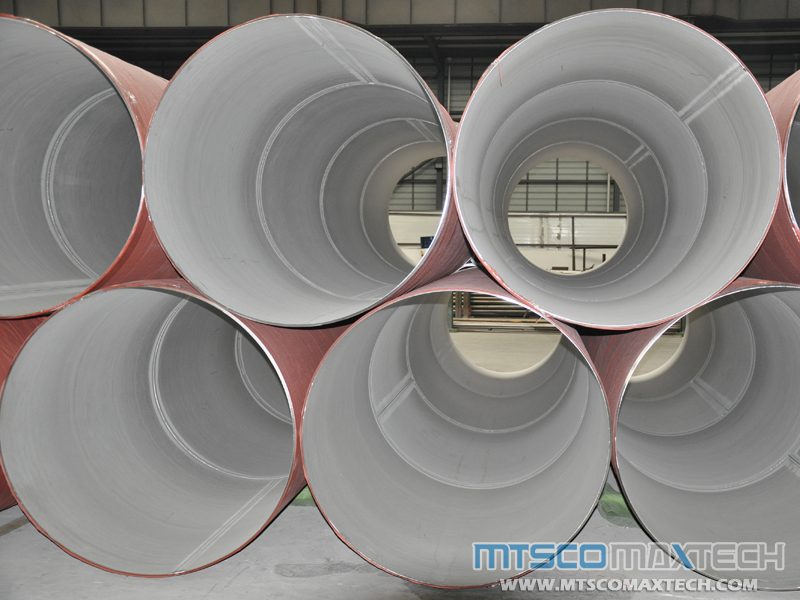

Examples include butt welding of strips, profiles, wires, rebar, rails, boiler tubes, oil and gas pipelines.

(2) Butt welding of ring workpiece

For example, car rim and bicycle, motorcycle rim butt welding, a variety of chain ring welding.

(3) Assembly welding of components

To reduce the cost of rolling, forging, stamping or machining parts into complex parts.Such as car direction shaft housing and rear axle shell butt welding, butt welding of various connecting rod, rod, as well as special parts of butt welding, etc.

(4) Butt welding of heterogeneous metals

It can save precious metal and improve product performance. For example, butt welding of tool working part (high speed steel) and tail (medium carbon steel), butt welding of head (heat resistant steel) and tail (structural steel) of internal combustion engine exhaust valve, butt welding of aluminum-copper conductive joint, etc.

Through a simple understanding, we clearly know the two ways of butt welding and application fields.In a nutshell, butt welding has been widely used because of its high productivity and easy automation.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語