TP321/321H Stainless Steel Cold Rolled Tube, Boiler Tube

Material: Alloy 400, UNS N04400; Alloy 625, UNSN06625; Alloy 601, UNSN06601; Alloy 600, UNSN06600; Alloy 825, UNSN08825, 2.4858; S32750,1.4410, 2507, F53; S32205, S31803, 1.4462; 316L, 1.4401, 1.4404, 1.4435; 304L, 1.4306, S30403, 1.4307;

Get Quote

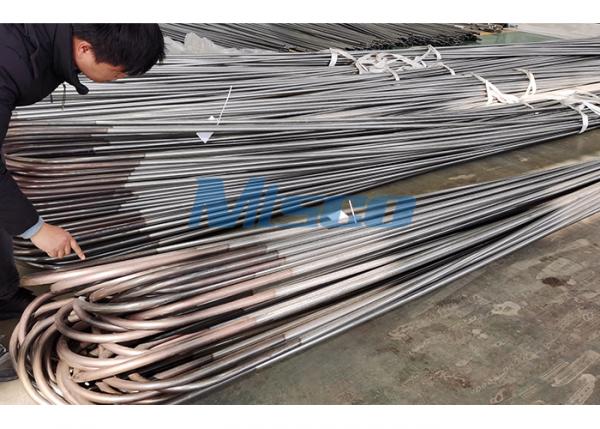

Sainless steelseamless boiler tubes

Stainless steel seamless boiler tube consists of iron, carbon and other alloying elements, with high hardness, toughness and ductility.

Stainless steel seamless boiler tube is a widely used product in industrial piping industry, which has excellent high temperature, corrosion and pressure resistance properties, and is suitable for a variety of high-pressure, high-temperature and highly corrosive working environment.

The common materials of stainless steel seamless boiler tube are as follows:

304 stainless steel: suitable for general water quality, air, food and beverage and other low corrosive media transportation.

316 stainless steel: suitable for seawater, chemical, paper and other highly corrosive media transportation.

321 stainless steel: suitable for petroleum, fertilizer, nuclear power and other high-temperature media conveying.

347 stainless steel: suitable for oil cracking, ammonia and other high temperature and high pressure media transportation.

ASTM A213 TP321/321H 19.05mm Stainless Steel Tubing Cold Rolled For Boiler

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products .

| Grade | TP304 ; TP304H ; TP304L ; TP316 ; TP316L ; TP 321 ; TP321H ; TP317L ; TP310S ; TP347H |

Standard | ASTM A213 , ASTM A 269 , ASTM A 270 , EN10216-5 ; ASTM B 622 ; ASTM B516 ; ASTM A789 , etc |

| Size | Routine OD : 19.05mm,25.4mm,31.8mm,38.1mm |

| WT :1.2-2.77mm | |

| Length | According to customer needs up to 20m |

| Advantage | Superior surface finish , better mechanical property ; more precise dimension ; perfect inspection method and inspection equipment |

| Application | Boiler tube applies to petroleum , chemical industry , electric power , boiler , high temperature resistant , low temperature resistant , corrosion resistant . The size can be made according to the customers requirements . High pressure boiler pipe applies to container , petrochemical and so on . Note : Generally , high pressure boiler pipe’s working pressure above 9.88Mpa and working temperature between 450 to 650 . |

| Package | Plywood case |

ASTM A269 Heat ExchangeTube Material Chemical Composition :

| Elements | 304L(wt%) S30403 | 304(wt%) S30400 | 316L (wt%) S31603 | 316 (wt%) S31600 |

| (C) Carbon, max | 0.035 | 0.08 | 0.035 | 0.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 12.0 | 8.0 - 11.0 | 10.0 - 14.0 | 10.0 - 14.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 |

| (Fe) Iron | Bal. | Bal. | Bal. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

Heat Exchange Tube Application :

a) Petroleum , chemical enterprise , super heater of boiler and heat exchanger

b) High temperature-resistant transmission fluid pipe in power station

c) Ship with pressure pipe

d) Exhaust purification device

e) Construction and ornament

f) solar industry , military , semiconductor etc

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

1.4462 S32205 / 2205 Duplex Steel Tube Hydraulic Test With Pickling Surface For Sea Treatment

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語