Why is there no seam in seamless steel pipe?

How much do you know about seamless steel pipe? Seamless steel pipe is a kind of round, square, rectangular steel with hollow cross section and no seam around. Seamless steel pipe is made from ingots or solid billets that are perforated to make a burr pipe and then hot rolled, cold rolled or cold dialed. Seamless steel pipe has a hollow cross-section and is used in large quantities as a pipeline for transporting fluids and is widely used in the manufacture of structural and mechanical parts.

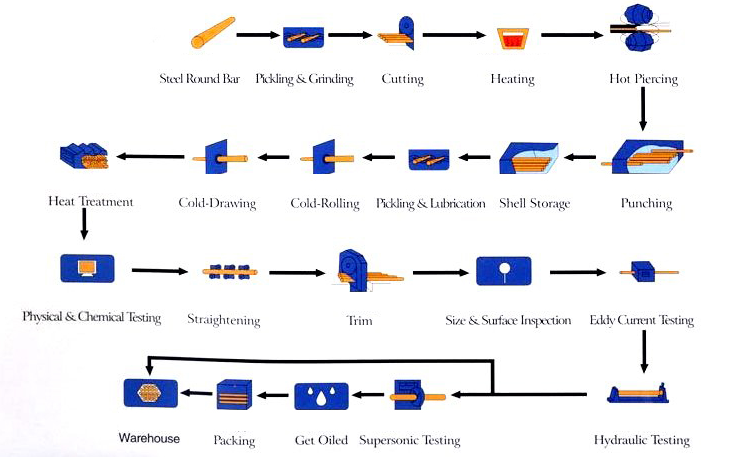

Production process of seamless steel pipe:

① Hot rolled seamless steel pipe main production process.

Pipe billet preparation and inspection → pipe billet heating → perforation → pipe rolling → barren pipe reheating → fixing (reducing) diameter → heat treatment → finished pipe straightening → finishing → inspection (non-destructive, physical and chemical, stage inspection) → storage

②Main production process of cold rolled (drawn) seamless steel pipe

billet preparation → pickling lubrication → cold rolling (drawing) → heat treatment → straightening → finishing → inspection

Seamless steel pipe classification:

1. According to the shape of the section: round section pipe, shaped section pipe

2. According to the material: carbon steel pipe, alloy steel pipe, stainless steel pipe, composite pipe

3. According to the production method: hot-rolled pipe, cold-rolled (drawn) pipe

4. By application: boiler pipe, oil well pipe, pipeline pipe, structural pipe, fertilizer pipe ......

Seamless steel pipe development history:

Seamless steel pipe production has a history of nearly 100 years. German Mannesmann brothers in 1885 first invented the two-roller slant-rolling perforating machine, and in 1891 invented the cycle rolling machine, in 1903 the Swiss Stiefel (R.C. Stiefel) invented automatic rolling machine, and later appeared in a continuous rolling machine and top pipe machine and other extension machines, began to form the modern seamless steel pipe industry.

In the 1960s, due to the improvement of the continuous rolling mill, the emergence of three-roller perforating machine, improved production efficiency and enhanced the ability of seamless pipes to compete with welded pipes. 70s seamless pipes and welded pipes are running neck and neck, and the world's steel pipe production is increasing at a rate of more than 5% per year.

China has attached importance to the development of seamless steel pipe industry since 1953, and has formed a preliminary production system for rolling various large, medium and small pipes.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語