Flanges Forged / Casting Fittings

Flange Manufacturer with Complete Inspection Process and QC Team.

Flanges are essential components in industrial piping systems, serving as connectors for pipes, valves, pumps, and other equipment. These flat or circular discs with evenly spaced holes allow for easy assembly and disassembly of the system, making maintenance and modifications more efficient.

Flanges come in various types, with the most common being weld neck, slip-on, socket weld, lap joint, and blind flanges. Each type is designed for specific applications.

In addition to joining components, flanges provide key benefits, including stress distribution, leak prevention, and the ability to access the interior of the piping system. They are critical in industries like oil and gas, petrochemical, and manufacturing.

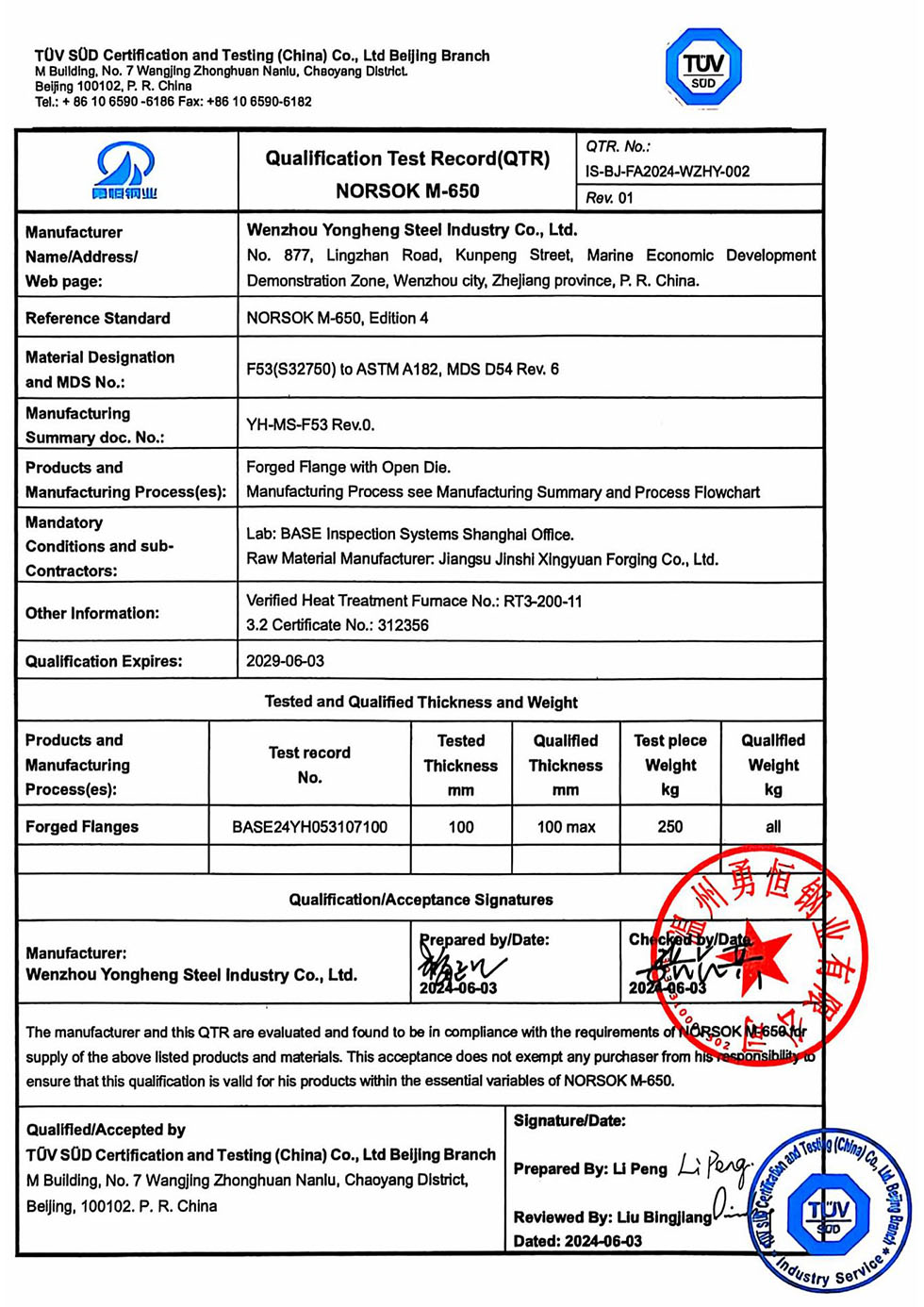

MTSCO flange has a highly guaranteed supply chain. Since 2018, MTSCO flange business matured and invested in our own flange manufacturer-Yongheng Steel. Yongheng is fully responsible for all flange orders from MTSCO, and operates around the clock to maximize the cost performance of flanges.

VIP SERVICE

VR (Virtual) Mill Introductionn

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Flanges/Forged/Casting Fittings

| Type | Outer Diameter | Standard | Materials | |

| Flanges | 21.3-2032mm DN15-DN2000 1/2’’-80’’ |

ASME B16.5/16.47/ |

Austenitic | F304/L, F316/L, F316Ti... |

Forged Fittings |

13.7-114.3mm DN8-DN100 1/4’’-4’’ |

Duplex Steel | F51/2205/S32205 F53/2507/S32750... |

|

Casting Fittings |

10.3-114.3mm DN6-DN100 1/8’’-4’’ |

Nickel Alloy Cobalt Alloy | 600/ 800/ C Series... Alloy 188/ L-605/ 6B... | |

Products

Quality Control of MTSCO Flanges

1. Secondary Inspection of Raw Materials

MTSCO raw materials come from large factories such as Baosteel, TSINGSHAN, Yongxin...Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI, appearance, heat no checking, physical and chemical and other inspections, to ensure that they meet the requirements.

Next, the raw material will be produced from cutting, forging, solid solution for flange blanks, through 100% visual inspection, 2% NDT, physical and chemical testing, etc., to confirm that the blanks are qualified. All experimental results are archived.

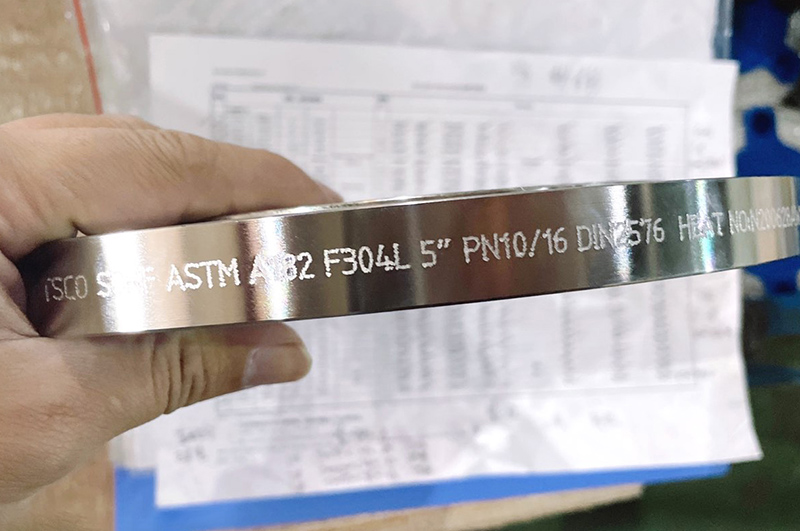

2. Traceability of the Production Process

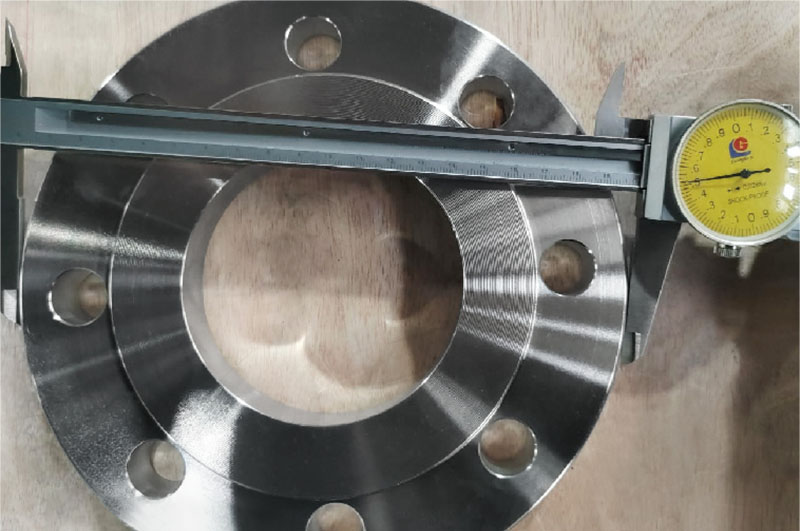

The director receives the blanks from warehouse according to the production plan, and with the process flow card, the blanks are processed by turning, drilling, marking, cleaning and other procedures. The first flange programmed by CNC each time is supervised by the director, who confirms that it is qualified and then continues production. Every 10 subsequent pieces are measured by the machinist and the measurement data is recorded. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.

3. Inspection before Shipment

MTSCO has professional QC team to inspect the dimensions of the flange, verify the spray code, inspect the appearance, and take photos to record. We did not conduct a 100% inspection because we firmly believe that good quality must be produced through management, not inspection. Therefore, we have invested a lot of effort in production control to ensure the quality of the final product. In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

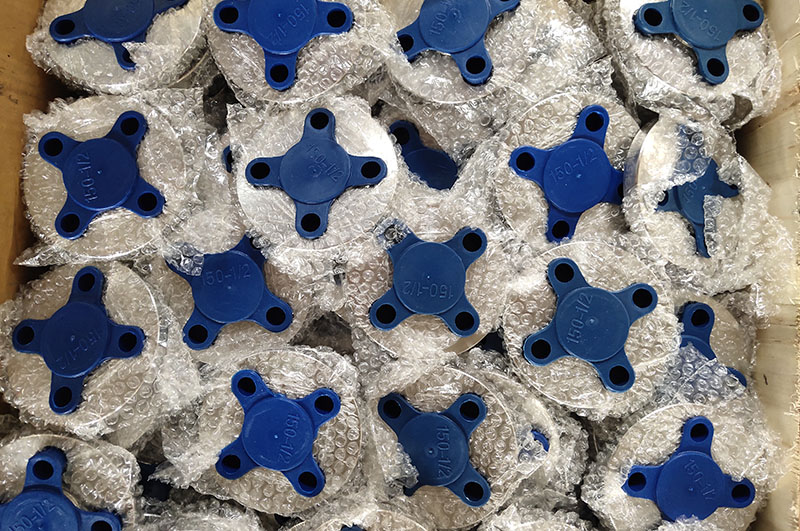

Package

Protective Cover + Separate Foam Bag

Wooden Box

Container Reinforcement

Project Cases

| Year | Project | End User/ EPC | Site | Material | Products | QTY(KGS) |

| 2020 | K56 Methane Gas to Power Plant. | Shema Power Lake Kivu Limited. | Rwanda | 316L | SMLS Pipe 1/2"-20"/BW Fittings Flanges |

250,000 |

| 2021-2022 | Building New Factory in Israel | Intel | Israel | 304L | Welded Pipe 8''/10''/16'' 10S BW Fittings Flanges |

60,000 |

| 2023 | PROJECT SAHARA ROSE | Petronas | Malaysia | 304/L 316/L |

SMLS Pipe Welded Pipe Fittings |

50,000 |

| 2022-2023 | P78 | Petrobras | Brazil | N06625 | Plate/Fitting/Flange | 10,000 |

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語