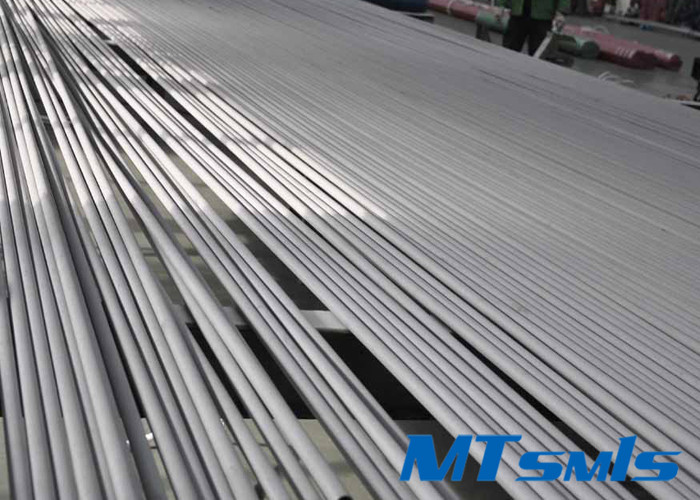

S31803/2205 Duplex Steel Chemical Tube,ASTM A789 Tube

SSDST25

Price: From $5500-8000USD/TON

Material: S32205, S31803, 1.4462;

Get Quote

1 / 4 Inch ASTM A789 S31803 Stainless Steel Duplex Steel Tube NDT For Chemical Industry

| Grade | Standard | Outside Diameter | 3.18mm-38mm |

| S31803/2205 S32750/2507 S32760 | ASTM-A789 ...... | Wall Thickness | 0.5mm-3mm |

| Length | ≤30m | ||

| Surface | Bright Annealed/ Polished/ Annealed Pickled | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

Quality Control of MTSCO Duplex Tube:

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| 2205 | ||||||||||

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| 2507 | ||||||||||

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

Features of ASTM A789 Tube:

Annealed Pickled VS Polished Surface:

ASTM A789 Duplex Steel Seamless and Welded Tubing

ASTM A789 is a standard specification developed by the American Society for Testing and Materials (ASTM) that covers general requirements for seamless and welded ferritic/austenitic stainless steel tubes. These tubes are categorized according to different steel grades, such as S31803, S32205, etc., each of which has a different chemical composition and mechanical properties.

ASTM A789 standard seamless and welded duplex steel pipe has several outstanding properties that make it stand out in many piping applications:

1. Duplex structure: Duplex steel pipe has two different crystal structures, austenite and ferrite, giving the pipe excellent strength and corrosion resistance.

2. Good corrosion resistance: These pipes perform well against corrosive media such as brines, chlorides and acids. 3.

3. High Strength: Duplex pipes have excellent tensile strength and are capable of withstanding high pressures, making them suitable for use in high pressure piping systems.

4. Wide Temperature Range: ASTM A789 standard pipe can be operated over a wide range of temperatures, including very low and high temperature conditions.

5. Excellent weldability: These pipes are easy to weld and can meet the needs of a variety of projects

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

3 / 4 Inch S32750 / S32760 Small Diameter Duplex Steel Tube With Rapid Cooling

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc Outer Diameter: 3.18mm - 101.6mm Wall Thickness: 0.5mm - 20mm Length: as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5etc. Application a) Petroleum b) Chemical indust......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語