Alloy 31 Pipe, ASTM B622 UNS N08031 Seamless Nickel Alloy Pipe

Get Quote

Alloy 31 Pipe, ASTM B622 UNS N08031 Seamless Nickel Alloy Pipe

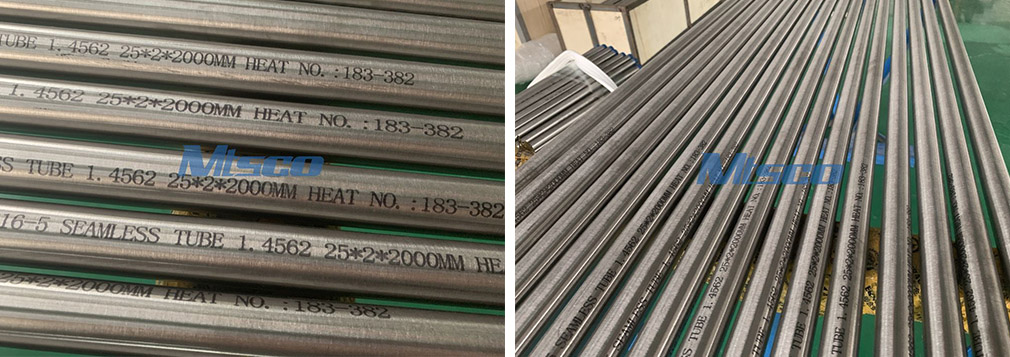

| Grade | Standard | Outside Diameter | 219mm-3000mm |

Alloy 31 Alloy 600 Alloy 601Alloy 625 Alloy 825 Alloy 800/800H/800HT Alloy C276 Alloy C22 Alloy 400 Alloy K500 Alloy 200 Alloy 201 ... | ASTM-B619 ASTM-B705 ASTM-B725 AMS5796 ... | Wall Thickness | 4mm-60mm |

| Length | ≤12m | ||

| Inspection | Appearance/Size/PMI Inspection NDT:100%X-Ray/ET/UT/HT... Mechanical Testing Third Party Inspection | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

Chemical Composition of Nickel Alloy 31:

| % | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | N | other |

| min | - | - | - | - | - | 26 | 30 | 1 | 6 | 0.15 | Fe:tolerance |

| max | 0.15 | 0.3 | 2 | 0.02 | 0.01 | 28 | 32 | 1.4 | 7 | 0.25 |

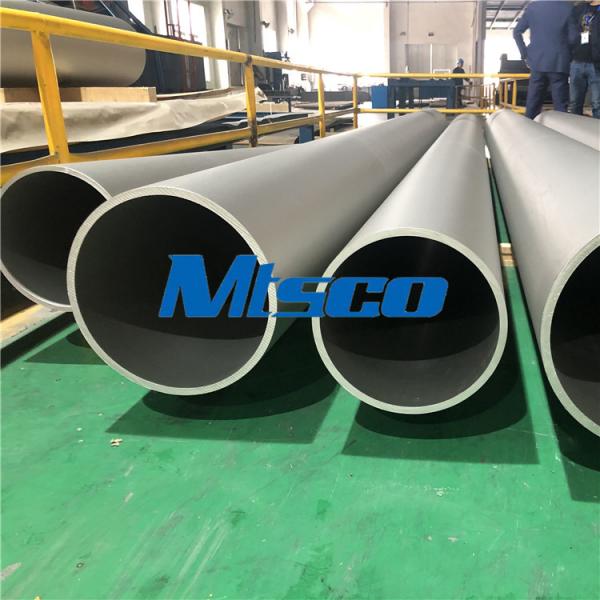

What is Nickel Alloy 31?

Alloy 31 (N08031) nickel-based alloy is a nitrogen-containing iron-nickel-chromium-molybdenum alloy with properties intermediate between super austenitic stainless steels and established nickel-based alloys.Alloy 31 (N08031) nickel-based alloy is suitable for applications in the chemical and petrochemical industries, in environmental engineering, and in the production of oil and gas.

Characteristics:

Excellent corrosion resistance in halogenated media, whether acidic or alkaline.

Excellent corrosion resistance in sulfuric acid at any concentration.

Excellent corrosion and erosion resistance in phosphoric acid media .

Excellent resistance to localized and uniform corrosion in chlorine dioxide bleach media.

Excellent corrosion resistance in both reducing and oxidizing environments.

Easy to process and weld.

Has the certification that can be used to manufacture pressure vessels with a wall temperature of -196~450℃.

Alloy 31 high temperature alloy has a wide range of applications. It is commonly used in the production of various types of electromechanical equipment with high-performance requirements, storage tanks for strong acids and alkalis, automotive exhaust gas processors, treatment of concentrated sulfuric acid and other equipment in the industrial field, as well as related devices in the field of aviation and medicine.

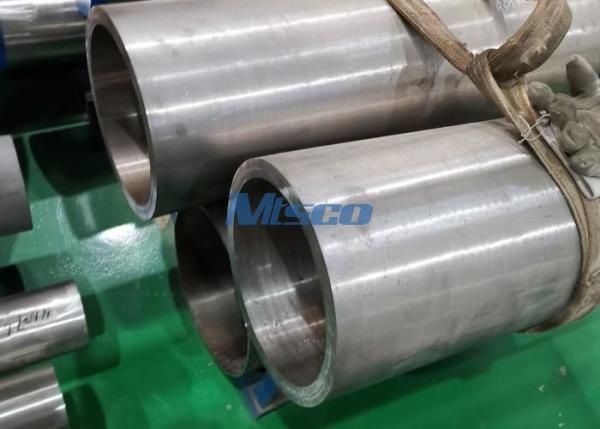

The Surface Treatment of Shot Peening:

Surface shot peening of pipes is a surface treatment method in which powerful metal particles or abrasives are blasted at high speeds onto the surface of metal pipes through the use of shot peening equipment. This process removes oxidation, rust, oil and other impurities from the surface, thereby improving the quality and cleanliness of the metal surface.

The principle of the blasting process is to utilize the impact and friction of the abrasive material to effectively clean the metal surface, making it more uniform and smooth and improving the surface roughness of the metal. This not only helps to improve the surface quality of the metal, but also provides a better basis for subsequent painting, plating or other surface treatments.

Surface blasting is widely used in the manufacturing industry, especially in the preparation of metal pipes, steel structures and other metal products. This process helps to improve the corrosion resistance and extend the service life of metal products and also provides a better basis for adhesion to subsequent processes.

Why Choose MTSCO Nickel Alloy Seamless Pipe?

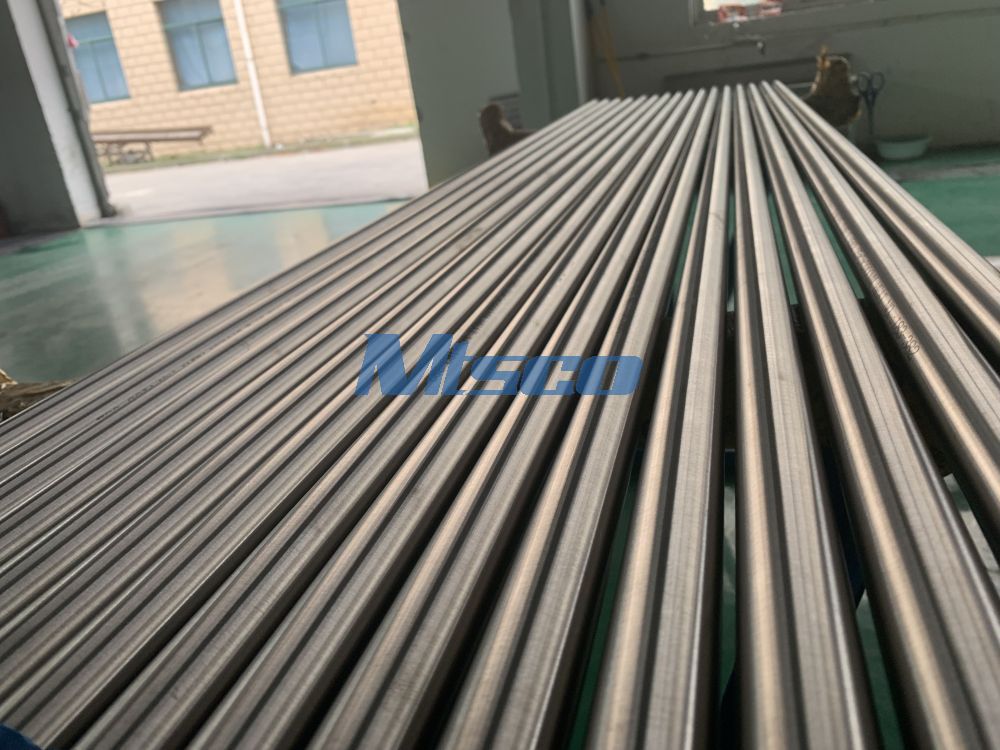

Huxin Pipe, a seamless steel pipe manufacturer owned by MTSCO Investments, is trusted for its 36 years of experience in pipe manufacturing. The factory not only supplies regular sized pipes, but can also provide extended pipe lengths of 18 and 25 metres to meet the needs of different customers.

Huxin Pipe's factory is well-equipped, including cold rolling mill, annealing furnace, pickling tank, ultrasonic eddy current machine, and physical and chemical laboratories, etc. These advanced equipments provide a strong guarantee for the manufacturing of seamless steel pipes.

In terms of quality control, HUXIN PIPE has a set of perfect quality control process, and professional MTSCO QC inspectors are involved in the whole process of control before, during and after production, which provides customers with more reliable product quality guarantee.

In addition, Huxin Pipe's products have passed ISO, PED and AD2000 certifications, which proves its strength and reputation in quality.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

ASTM B163 / B165 Alloy 400 / UNS N04400 Nickel Alloy Seamless Pipe

Monel 400, also known as Alloy 400, is a very well known nickel-copper alloy material. This alloy consists primarily of nickel (usually containing at least 63%) and copper, and also contains small amounts of iron, carbon, silicon, and manganese.Monel 400 is widely acclaimed for its excellent corrosi......

ASTM A829 Alloy 400 6000MM Nickel Alloy Steel Seamless Pipe

Nickel alloy is one of MTSCO’s main products. We have finalized the integration flow process that covered everything from smelting to forging, machining to finished product. We consider that every kind of performance testing, checking, and analysis is very significant to assess the processing ......

ASTM B622 / B619 Alloy C-2000 / UNS N06200 Nickel Alloy Pipe

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

AMS 5581F UNS N06625 Seamless Nickel Alloy 625 Pipe For Aerospace

Nickel Alloy 625 Pipe, Alloy 625 Seamless Pipe, is a highly corrosion-resistant, high-strength, high-temperature-stable nickel-based alloy pipe. Adopting advanced heat treatment process, the pipe excels in acid, alkali and oxidation resistance. Its excellent corrosion resistance makes it ideal for u......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語