Alloy 601 UNS N06601 Nickel Alloy Tube

SSNAT05

Price: From $31000-50000USD/TON

Material: Alloy 600, UNSN06600;

Get Quote

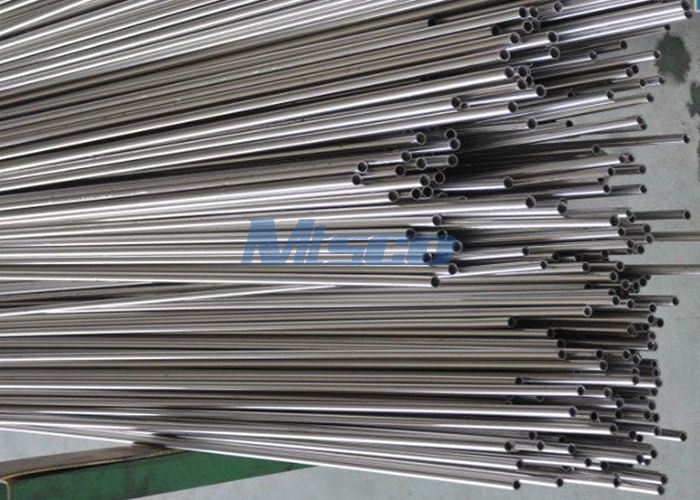

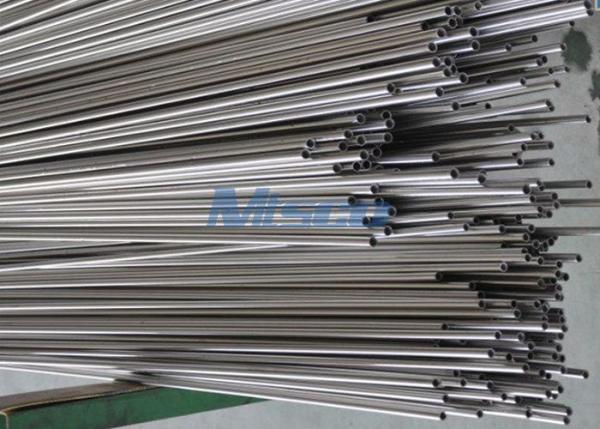

Alloy 600 / 601 UNS N06600/ N06601 Nickel Alloy Tube

1. Grade : Alloy625 / N06625 ,Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 ,Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc

2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm

3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm

4 . Length : As customer's requirement

5 . Standard : ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

6 . Technology : Cold Drawn / Cold Rolled

Chemical composition:

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

Physical properties:

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

Features:

High Temperature Resistance: Alloy 601 tubing is capable of maintaining stable performance under extreme high temperature conditions, and its high temperature resistance makes it ideal for use in a variety of high temperature environments.

Corrosion resistance: Nickel alloy tubing Alloy 601 shows excellent resistance to a wide range of corrosive media, including acids, alkalis, oxides, etc., resulting in excellent durability in corrosive environments.

Excellent Mechanical Properties: Alloy 601 tubes have good mechanical properties, including high strength, excellent toughness and fatigue resistance, which can meet a variety of engineering needs.

Good Thermal Expansion Properties: Alloy 601 has good thermal expansion properties at elevated temperatures, which reduces stress and distortion due to temperature changes.

Ease of processing: this nickel alloy tube is easy to process into various shapes and sizes, suitable for a variety of processes to meet the needs of different applications.

Test :

1 . NTD(Ultrasonic test, Eddy Current test)

2 . Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test)

3 . Metal Test(Metallographic Analysis, Impact Test-High/low temperature)

4 . Chemical Analysis(Photoelectric Emission Spectroscopic)

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM A213 S30400 / 30403 Small Diameter Stainless Steel Seamless Tube For Instrument

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely a......

Alloy 600 / 601 UNS N06600/ N06601 Nickel Alloy Tube

1. Grade : Alloy625 / N06625 ,Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 ,Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm 3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm 4 . Length : As ......

Alloy K500 / UNS N05500 ASTM B163 / B165 Seamless Nickel Alloy Tube With Eddy Current

1. Material Grade: UNS N05500,N10276, UNS N1001, UNS N10665, UNS N10675, UNS N06022,N08800,N08825, N04400; etc 2. Outer Diameter: 3.18mm-101.6mm Wall Thickness: 0.5mm-20mm 3. Length: Normally fixed length 6m, can as per customer’s requirement 4. Standard: ASTM B163; ASTM B167; ASTM B444; ASTM B......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語