ASTM B829 / B167 Nickel Alloy 600/UNS N06600 Seamless Thermocouple Protective Tube For Oilfield

SSNAT06

Get Quote

ASTM B829 / B167 Nickel Alloy 600/UNS N06600 Seamless Thermocouple Protective Tube For Oilfield

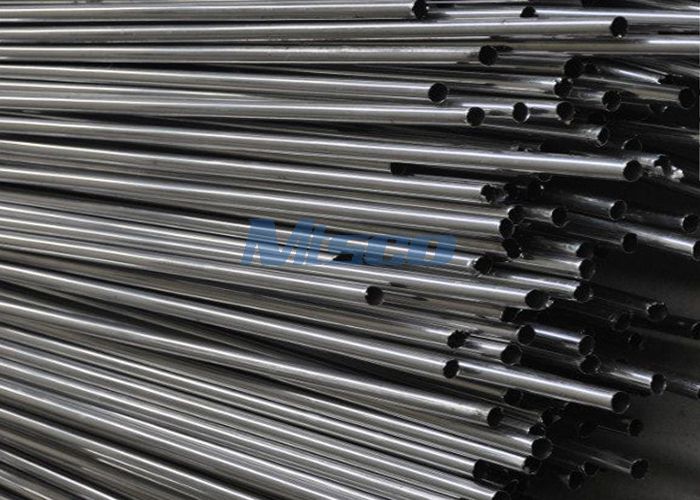

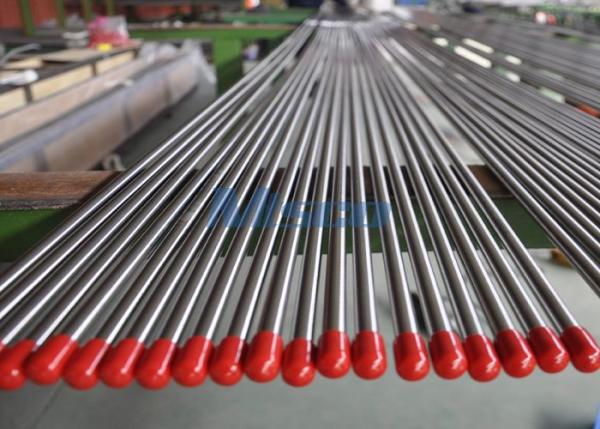

Seamless thermocouple protective tube is a type of seamless tube used to protect thermocouples. A thermocouple is a sensor used to measure temperature and usually consists of wires made of two different metals or alloys. A seamless protective tube is used to place the thermocouple in the object to be measured or in the environment while protecting it from corrosion, mechanical damage, or other external influences.

These protection tubes are usually made of high temperature resistant alloys or ceramic materials with good resistance to heat, corrosion and abrasion. They are often designed to take into account the temperature, pressure, chemical properties, and other environmental factors in the environment to ensure that the thermocouple is able to measure temperature accurately and reliably.

Features:

Alloy 600 has good resistance to corrosion and high temperature, and has high strength and good fabricability. It resists chloride-ion-incurred stress corrosion cracking, sulfur compounds and oxidizing conditions at high temperatures.

Alloy 600 Tube Material Grade:

| Material Grade | Alloy 600/ N06600, Alloy 625/N06625, Alloy 601/N06601,Alloy 718/N07718, Alloy C276/N10276, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc |

| Outer Diameter | 3.18mm-101.6mm |

| Wall Thickness | 0.5mm-20mm |

| Length | Normally fixed length 6m, can as per customer's requirement |

| Standard | ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc |

ANSI B36.19 ASTM B829 / ASME SB829 Specifications :

| NPS Designator | Outside Diameter | Nominal Wall Thickness | ||||||||

| in. | mm | Schedule 5S | Schedule 10S | Schedule 4S | Schedule 80S | |||||

| in. | mm | in. | mm | in. | mm | in. | mm | |||

| 1 / 8 | 0.405 | 10.29 | … | … | 0.049 | 1.24 | 0.068 | 1.73 | 0.095 | 2.41 |

| 1 / 4 | 0.54 | 13.72 | … | … | 0.065 | 1.65 | 0.088 | 2.24 | 0.119 | 3.02 |

| 3 / 8 | 0.675 | 17.15 | … | … | 0.065 | 1.65 | 0.091 | 2.31 | 0.126 | 3.2 |

| 1 / 2 | 0.84 | 21.34 | 0.065 | 1.65 | 0.083 | 2.11 | 0.109 | 2.77 | 0.147 | 3.73 |

| 3 / 4 | 1.05 | 26.67 | 0.065 | 1.65 | 0.083 | 2.11 | 0.113 | 2.87 | 0.154 | 3.91 |

| 1 | 1.315 | 33.4 | 0.065 | 1.65 | 0.109 | 2.77 | 0.133 | 3.38 | 0.179 | 4.55 |

| 1 1 / 4 | 1.66 | 42.16 | 0.065 | 1.65 | 0.109 | 2.77 | 0.14 | 3.56 | 0.191 | 4.85 |

| 1 1 / 2 | 1.9 | 48.26 | 0.065 | 1.65 | 0.109 | 2.77 | 0.145 | 3.68 | 0.2 | 5.08 |

| 2 | 2.375 | 60.33 | 0.065 | 1.65 | 0.109 | 2.77 | 0.154 | 3.91 | 0.218 | 5.54 |

| 2 1 / 2 | 2.875 | 73.03 | 0.083 | 2.11 | 0.12 | 3.05 | 0.203 | 5.16 | 0.276 | 7.01 |

| 3 | 3.5 | 88.9 | 0.083 | 2.11 | 0.12 | 3.05 | 0.216 | 5.49 | 0.3 | 7.62 |

| 3 1 / 2 | 4 | 101.6 | 0.083 | 2.11 | 0.12 | 3.05 | 0.226 | 5.74 | 0.318 | 8.08 |

| 4 | 4.5 | 114.3 | 0.083 | 2.11 | 0.12 | 3.05 | 0.237 | 6.02 | 0.337 | 8.56 |

| 5 | 5.563 | 141.3 | 0.109 | 2.77 | 0.134 | 3.4 | 0.258 | 6.55 | 0.375 | 9.52 |

| 6 | 6.625 | 168.28 | 0.109 | 2.77 | 0.134 | 3.4 | 0.28 | 7.11 | 0.432 | 10.97 |

| 8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.5 | 12.7 |

| 10 | 10.75 | 273.05 | 0.134 | 3.4 | 0.165 | 4.19 | 0.365 | 9.27 | 0.5 | 12.7 |

| 12 | 12.75 | 323.85 | 0.156 | 3.96 | 0.18 | 4.57 | 0.375 | 9.52 | 0.5 | 12.7 |

| 14 | 14 | 355.6 | 0.156 | 3.96 | 0.188 | 4.78 | / | / | / | / |

| 16 | 16 | 406.4 | 0.165 | 4.19 | 0.188 | 4.78 | / | / | / | / |

| 18 | 18 | 457.2 | 0.165 | 4.19 | 0.188 | 4.78 | / | / | / | / |

| 20 | 20 | 508 | 0.188 | 4.78 | 0.218 | 5.54 | / | / | / | / |

| 22 | 22 | 558.8 | 0.188 | 4.78 | 0.218 | 5.54 | / | / | / | / |

| 24 | 24 | 609.6 | 0.218 | 5.54 | 0.25 | 6.35 | / | / | / | / |

| 30 | 30 | 762 | 0.25 | 6.35 | 0.312 | 7.92 | / | / | / | / |

Test :

1 . NTD(Ultrasonic test, Eddy Current test)

2 . Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test)

3 . Metal Test(Metallographic Analysis, Impact Test-High/low temperature)

4 . Chemical Analysis(Photoelectric Emission Spectroscopic)

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Polished Tube

ASTM B829 / B167 Nickel Alloy 600/UNS N06600 Seamless Thermocouple Protective Tube For Oilfield

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

ASTM B677 / B829 Alloy 926 / UNS N08926 Nickel Alloy Seamless Tube

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

ASTM B167 Nickel Alloy Tube Bright Annealing Inc 600 / 601 , 100 % PMI Test

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語