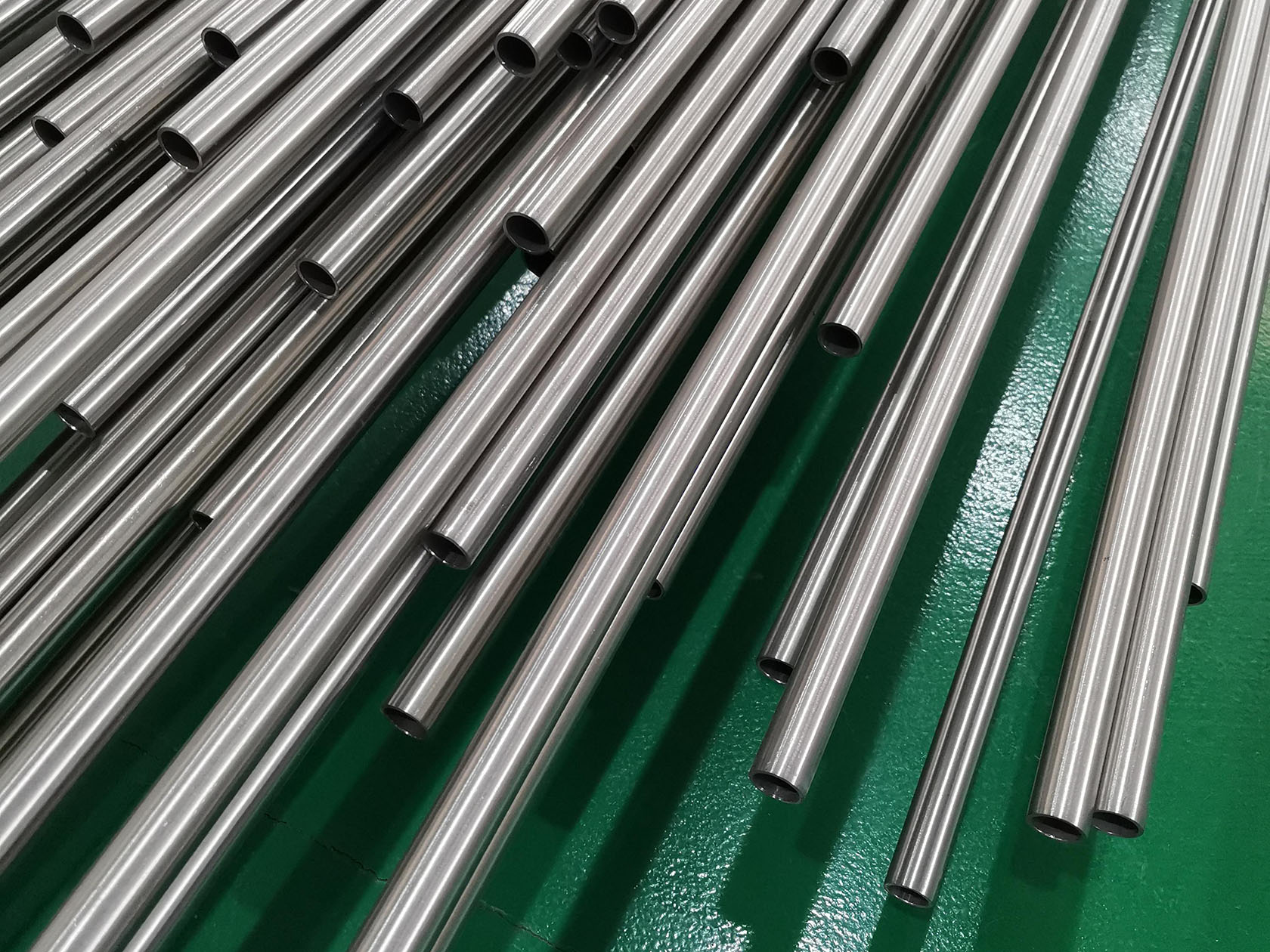

ASTM B161 UNS N02201 Ni 201 Nickel Alloy Seamless Pipe Tube

![]() ASTM B161 Standard Specification PDF Download

ASTM B161 Standard Specification PDF Download

Do you know what the properties of alloys of pure nickel are?

Alloy 201 shows good stability in corrosive media such as acids, alkalis and salts and is widely used in industrial fields such as petrochemicals, aerospace, power generation and marine engineering.

Nickel201 Nickel Alloy Chemical Composition and Preparation

The chemical composition of Nickel201 nickel alloy is mainly composed of pure nickel (Ni) and trace impurities, in which iron (Fe), silicon (Si), copper (Cu), manganese (Mn), carbon (C) and other elements have low content. Precise proportioning and strict control of process parameters during preparation are crucial to the performance of the alloy.

Nickel201 nickel alloy physical properties

Nickel201 nickel alloy has a high melting point (about 1455°C) and density (about 8.89 g/cm³), which makes it stable in high-temperature environments. Its coefficient of linear expansion is approximately 13.3 x 10^-6/°C, exhibiting low thermal expansion, which is conducive to maintaining dimensional stability at high temperatures.

High purity: Nickel201 is 99.6% pure and free of impurities and inclusions, ensuring its excellent physical and chemical properties.

- Corrosion resistance: Nickel201 has excellent corrosion resistance in a variety of corrosive media such as acids, alkalis and salts, and has good stability for some strong acids and alkali solutions.

- High-temperature strength: Nickel201 has excellent high-temperature strength, can maintain good mechanical properties in high-temperature environments, such as high-temperature alloys in the jet engine components.

201 stainless steel tube has: acid resistance, alkali resistance, high density, no pinhole, etc., is the production of a variety of cases, straps bottom cover quality materials, etc. 201 stainless steel tube can be used to do decorative tubes, industrial tubes, some shallow tensile products.

Ni201 steel pipe as a high-performance nickel-based alloy steel pipe, with its excellent corrosion resistance, high temperature stability and excellent mechanical properties, has demonstrated its irreplaceable role in a number of industrial fields. Whether in petrochemical, aerospace, power generation or marine engineering, Ni201 steel pipe provides a solid guarantee for the development of various industries with its reliable quality and performance.

Related Products

ASTM B444 / B829 Alloy 625 Nickel Alloy Seamless Tube

1. Grade : Alloy625 / N06625 , Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 , Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc 2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm 3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm 4 . Length : As cus......

Inc 625 / Inc 617 UNS N06625 / N06617 Bright Annealed Nickel Alloy Tube With High Strength

Alloy 625 Metallurgical structure: 625 is face-centered cubic lattice structure. Dissolve out the carbon granule and instability quaternary phase, then change it to stability Ni3 (Nb,Ti) trimetric lattice around 650℃ after a long time heat preservation. nickel-chromium content will strength the me......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語