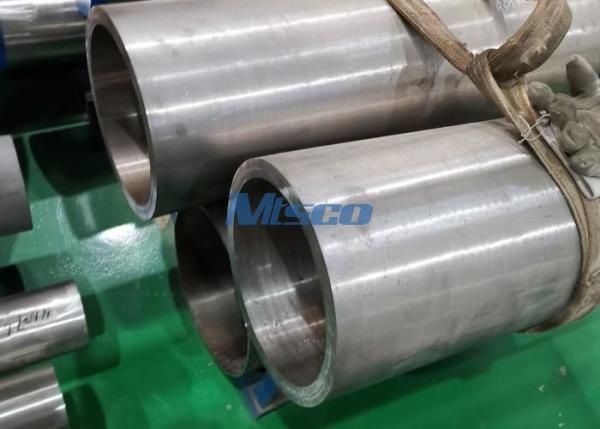

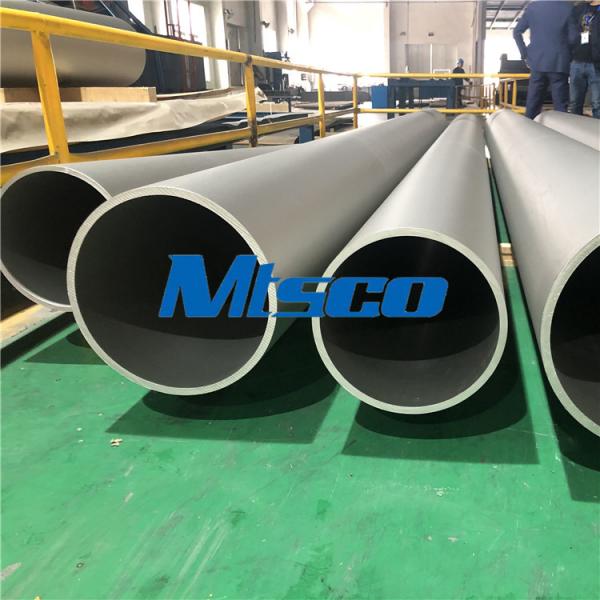

ASTM B165 UNS N04400 Monel 400 Seamless Pipe

![]() ASTM B165 Standard Specification PDF Download

ASTM B165 Standard Specification PDF Download

Characteristics and applications of Monel 400 pipes

Monel 400 alloy, mainly composed of nickel and copper, has excellent corrosion resistance and mechanical properties, and is widely used in petrochemicals, nuclear energy, national defense and other high-end industrial fields.

Monel 400 alloys are composed primarily of nickel and copper, typically containing 63% to 70% nickel and 28% to 34% copper, in addition to small amounts of iron, manganese, carbon, and silicon. These components give the alloy excellent corrosion resistance and mechanical properties. Therefore, Monel-400 alloy is used in large quantities for key components in advanced industrial fields such as petrochemical, nuclear and defense industries.

1. Excellent corrosion resistance: Monel 400 alloy tubes perform well in a wide range of corrosive media, especially in seawater, brine, organic acids, inorganic acids and a variety of salt solutions.

2. Easy to process: Monel 400 alloy tube has good processing performance, can be molded and processed by cold processing and hot processing and other ways. In addition, it can be connected by welding, brazing and fusion welding, etc., which is convenient for users to install and maintain.

Application areas of 400 alloy tubes

In the aerospace sector, N04400 alloy is used in the manufacture of high-temperature engine components, gas turbine blades, gas turbine parts and spacecraft parts. Its high-temperature performance and oxidation resistance help improve the efficiency and reliability of aero-engines. It is also used to manufacture fuel tanks and structural parts for spacecraft.

Alloy N04400 is used in desalination equipment such as stills and evaporators to convert seawater into fresh water. In addition, it is widely used in the field of marine resource development, for the manufacture of seabed mining equipment and ocean exploration equipment.

In the chemical industry, it is especially used in environments that require resistance to corrosion by strong acids, alkalis and salts. It is used to manufacture equipment such as chemical reactors, heat exchangers, storage tanks, pipelines and pumps. Its corrosion resistance makes it perform well under corrosive media such as sulfuric acid, nitric acid, hydrofluoric acid and chloride, and is widely used in corrosive environments in the chemical industry.

With the acceleration of global industrialization and the improvement of environmental protection requirements, the market demand for high-performance alloy tubes continues to increase.Monel 400 alloy tube as a tube with excellent corrosion resistance and mechanical properties, has a wide range of application prospects in a number of industrial fields. Especially in the fields of ocean engineering, chemical industry, oil and gas, the demand for Monel 400 alloy pipe will continue to grow. At the same time, with the continuous progress of technology and process optimization, the performance of Monel 400 alloy tube will be further improved, and the application areas will be continuously broadened.

Related Products

ASTM B163 / B165 Alloy 400 / UNS N04400 Nickel Alloy Seamless Pipe

Monel 400, also known as Alloy 400, is a very well known nickel-copper alloy material. This alloy consists primarily of nickel (usually containing at least 63%) and copper, and also contains small amounts of iron, carbon, silicon, and manganese.Monel 400 is widely acclaimed for its excellent corrosi......

ASTM A829 Alloy 400 6000MM Nickel Alloy Steel Seamless Pipe

Nickel alloy is one of MTSCO’s main products. We have finalized the integration flow process that covered everything from smelting to forging, machining to finished product. We consider that every kind of performance testing, checking, and analysis is very significant to assess the processing ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語