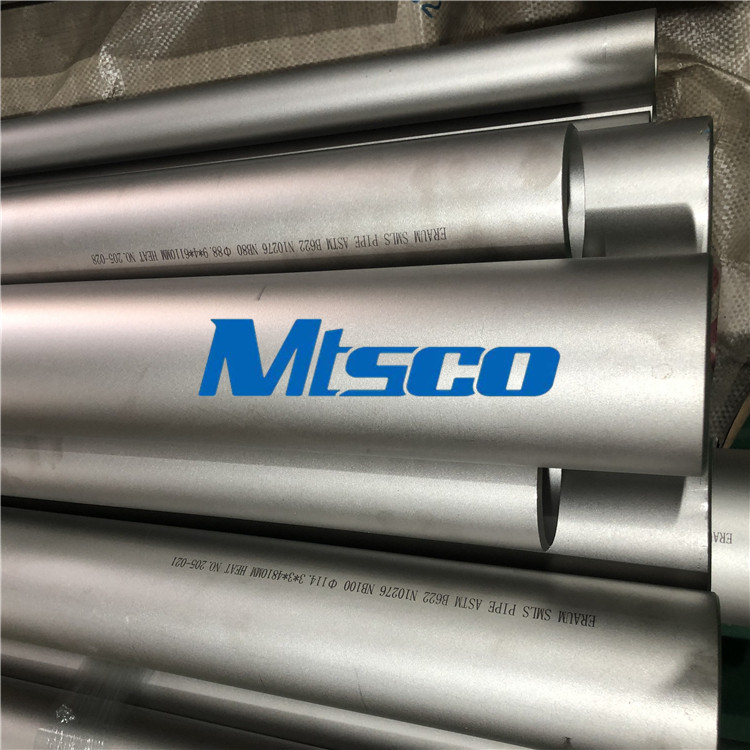

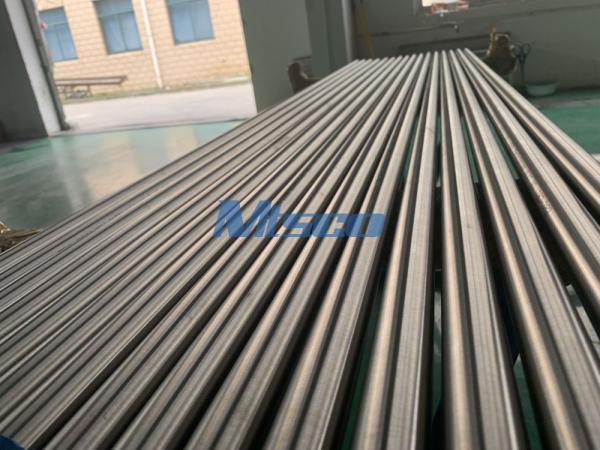

ASTM B622 Nickel Alloy C276 Seamless Pipe With Cold Rolled

C276 Pipe/Tube:

C-276 is a nickel-based alloy of nickel-molybdenum-chromium-iron-tungsten and is one of the most corrosion-resistant of modern metal materials. It is mainly resistant to wet chlorine, various oxidizing chlorides, chlorinated salt solutions, sulfuric acid, and oxidizing salts, and has good corrosion resistance in low and medium temperature hydrochloric acid.

Therefore, it has been widely used in harsh corrosive environments, such as chemical, petrochemical, flue gas desulfurization, pulp and paper making, environmental protection, and other industrial fields in the past three decades.

C276 Pipe/Tube Material Grade:

1. Material Grade: UNS N10276, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800,N08825, N04400; etc

2. Outer Diameter: 3.18mm-101.6mm

Wall Thickness: 0.5mm-20mm

3. Length: Normally fixed length 6m, can as per customer’s requirement

4. Standard: ASTM B169; ASTM B167; ASTM B444; ASTM B622 etc.

C276 Pipe/Tube Chemical composition:

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | - | - | - | - | - | - | - |

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

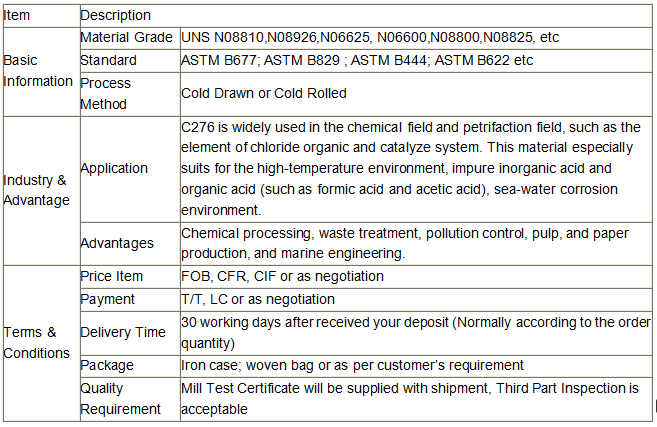

C276 Pipe/Tube Basic Information:

Alloy C276 / UNS N10276 Corrosion resistance:

C276 alloy suits many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist chloride corrosion, and tungsten makes its corrosion resistance better.C276 is one of a few materials that can resist the corrosion of most chlorine, hypochlorite, and chlorine dioxide, this alloy has prominent corrosion resistance to high concentration chlorate( iron chloride and copper chloride).

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

ASME SB163 / SB423 Nickel Alloy Seamless Alloy 825 Pipe

Apart from nickel being the primary alloying material in the alloy 825 electropolish pipe, the alloy also contains elements such as iron, chromium, titanium, molybdenum, and copper. Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments contain......

Alloy 556 / UNS R30556 Nickel Alloy Seamless Pipe For Boiler

1. Material Grade: Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030, Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556, etc. 2. Outer Diameter: 3.18mm-101.60mm; 10.3-426mm Wall Thickness: 0.50mm-20.00mm; 1.24-......

ASTM B829 Alloy 600 / 601 / 625 Nickel Alloy Seamless Pipe

Features of Nickel Alloy 600 Pipe: Corrosion resistance: Nickel alloy pipe is resistant to a wide range of chemical media, including acids, alkalis and salts, and is particularly resistant to chlorides. High-temperature resistance: In high-temperature environments, nickel alloy tubes maintain ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語