ASTM B574 Nickel Alloy Steel Alloy C22 / C276 Round Rod / Bar

MTNAPF23

Material: Alloy C-276,UNSN10276,2.4819; Alloy C-4, UNS N06455; Alloy C-2000, UNS N06200;

Get Quote

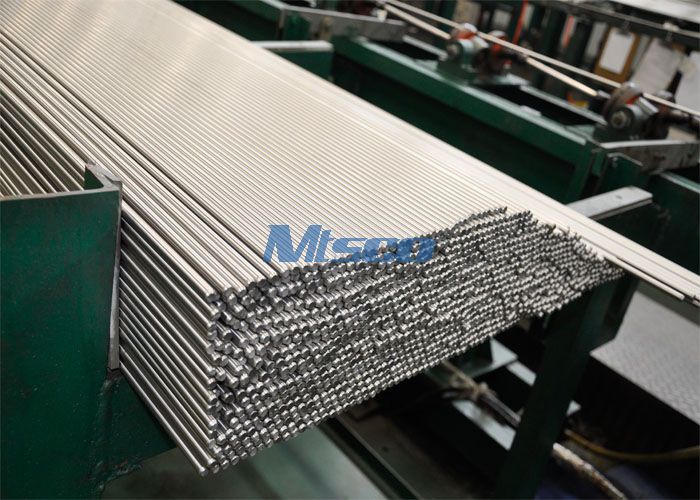

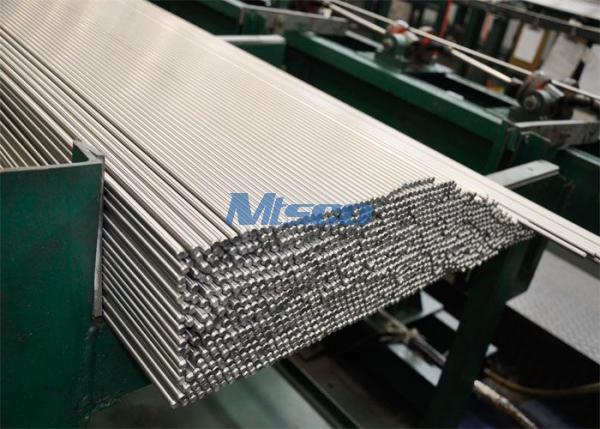

ASTM B574 Nickel Alloy Steel Alloy C22 / C276 Round Rod / Bar

1. Grade : Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022,Alloy 800/N08800,

Alloy 825/N08825, Alloy 400/N04400; etc

2 . Length : As customer's requirement

3 . Standard : ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc.

4. Technology : Cold Drawn / Cold Rolled

Chemical composition

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | |||||||

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

Features: Alloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Alloy C-276, Alloy C-4 and Alloy 625. Alloy C-22 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. So it can be used where “upset” conditions are likely to occur or in multi-purpose plants. Alloy C-22 has exceptional resistance to a wide variety of chemical process environments, including strong oxidizers such as ferric and cupric chlorides, chlorine, hot contaminated solutions (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions. It resists the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition.

Applications: Chemical processing involving acetic acid, acetic anhydride and complex acid mixture; pickling operations; cellophane manufacture; chlorination systems; electro-galvanizing rolls, expansion bellows; flue gas scrubber systems; geothermal wells; HF furnace scrubbers; incineration scrubbers; nuclear fuel reprocessing; pesticide production; phosphoric acid production; heat exchangers; selective leaching systems; sulfur dioxide cooling towers; sulphonation systems; and weld overlay.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: Slip On Flanges

ASTM B574 Nickel Alloy Steel Alloy C22 / C276 Round Rod / Bar

1. Grade :Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022,Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. 4. Technology : Cold Dr......

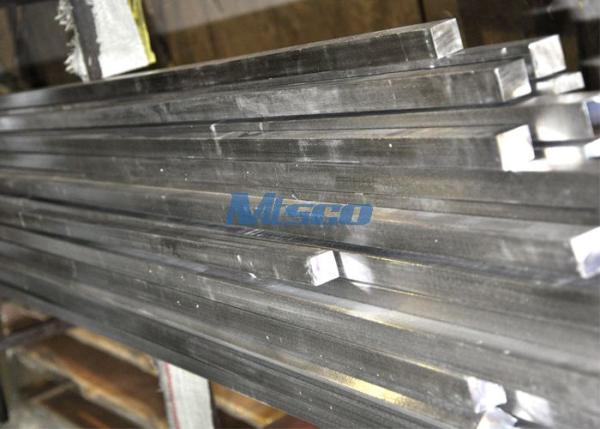

Alloy 601 / 617 Nickel Alloy Steel Square Rod / Bar, ASTM B166 For Chemical Industry

1. Grade :Alloy C276/N10276,Alloy B/UNS N10001, Alloy B-2/UNS N10665,Alloy B-3/UNS N10675,Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825,Alloy 400/N04400; etc 2 . Length : As customer's requirement 3 . Standard : ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. 4. Technology : Cold Drawn ......

Alloy 600 / 601 UNS N06600 / N06601 Nickel Alloy Steel Square Rod For Medical Industry

1. Material Grade: Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035 ,Alloy G-30 / UNS N06030, Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 etc. 2. Length: Normally fixed length 6m, can as per customer’s requirement 3. Standard: ASTM B335; ASTM B5......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語