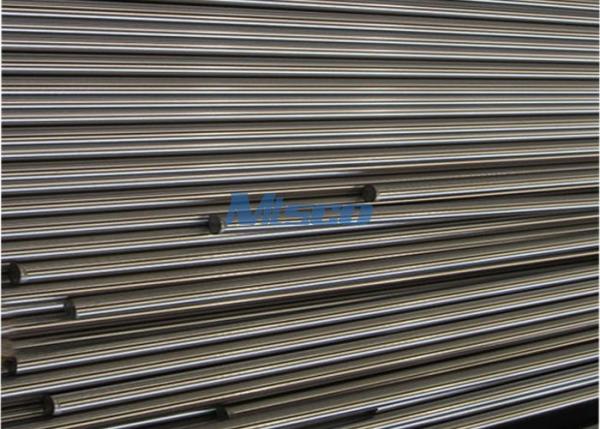

Nickel Alloy Steel Round Bar, ASTM B335 Alloy B-2 / B-3

MTNAPF22

Material: Alloy B, UNS N1001; Alloy B-2, UNS N10665; Alloy B-3, UNS N10675;

Get Quote

Nickel Alloy Steel Round Bar, ASTM B335 Alloy B-2 / B-3

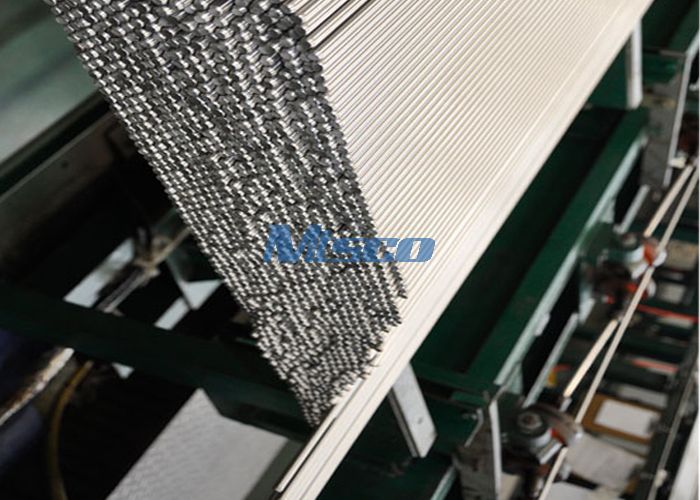

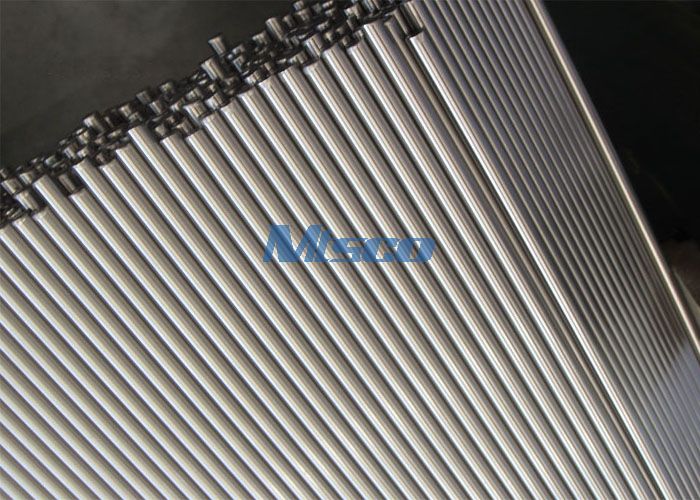

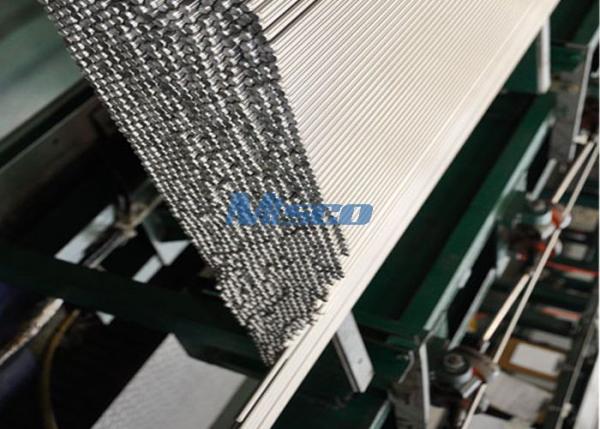

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . According to standard very strictly, nickel alloy tubes which produced by us always have correct OD and WT tolerance . Nickel alloy tubes have a very important position in thermocouple & cable industry .

Main market or alloy tube include Europe , Middle East , Southeast Asia , South America , etc . MTSCO has bright annealing alloy tube and pickling alloy tube . Compared these two kinds of tubes , bright annealed alloy tubes are more popular in the market . Because it has bright out and inner surface.

| Material Grade | Alloy C-4/N06455, Alloy B/UNS N10001,Alloy B-2/UNS N10665,Alloy B-3/UNS N10675,Alloy C22/UNS N06022,Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc |

| Length | can as per customer's requirement |

| Standard | ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. |

Chemical composition

| % | Ni | Mo | Fe | Cr | Co | C | Mn | Si | P | S |

| min | balance | 26.0 | ||||||||

| max | 30.0 | 2.0 | 1.00 | 1.00 | 0.020 | 1.00 | 0.10 | 0.040 | 0.030 |

Physical properties

| Density | 9.22 g/cm3 |

| Melting range | 1330-1380℃ |

Features: Alloy B-2 has outstanding resistance to hydrochloric acid at all concentrations and temperatures. It also has significant resistance to reducing environments like sulfuric, phosphoric, acetic acids and other nonoxidizing media. Alloy B-2 has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. Alloy B-2 has poor resistance to oxidizing environments, therefore, it should not be used where ferric or cupric salts are present as these salts may cause rapid corrosion failure.

Applications: Equipment handling reducing chemical environments; and chemical process industry involving hydrochloric, sulfuric, phosphoric and acetic acids.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: Slip On Flanges

Nickel Alloy Steel Round Bar, ASTM B335 Alloy B-2 / B-3

Material Grade: Alloy C-4/N06455, Alloy B/UNS N10001,Alloy B-2/UNS N10665,Alloy B-3/UNS N10675,Alloy C22/UNS N06022,Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Length:can as per customer’s requirement Standard: ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. MTSCO is a leading ma......

Alloy 600 / 601 UNS N06600 / N06601 Nickel Alloy Steel Square Rod For Medical Industry

1. Material Grade: Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035 ,Alloy G-30 / UNS N06030, Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 etc. 2. Length: Normally fixed length 6m, can as per customer’s requirement 3. Standard: ASTM B335; ASTM B5......

ASTM B443 Alloy 625 Nickel Alloy Steel Round Rod / Bar For Oil Industry

Material Grade: Alloy C-4/N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc Length: can as per customer's requirement Standard: ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. Features: Alloy 62......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語