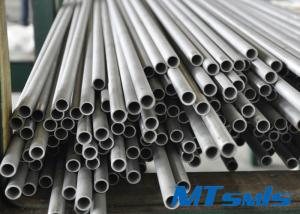

ASTM B725 Alloy 400/UNS N04400 Nickel Alloy Welded Tube

SSNAWT05

Material: Alloy 400, UNS N04400;

Get Quote

ASTM B725 Alloy 400 / UNS N04400 Nickel Alloy Welded Tube

Alloy 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Alloy 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It has good resistance in flowing seawater, but under stagnant conditions, pitting and crevice corrosion is induced. Alloy 400 is probably the most resistant to hydrofluoric acid in all concentrations up to the boiling point, of all engineering alloys. Alloy 400 is notable for its toughness, it does not show embrittlement tendency at cryogenic temperatures. It is work hardenable.

1. Material Grade: Alloy 400/N04400, Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy 800/N08800, Alloy 825/N08825; etc

2. Outer Diameter: 3.18mm-101.60mm

Wall Thickness: 0.50mm-20.00mm

3. Length: Normally fixed length 6m, can as per customer's requirement

4. Standard: ASTM B725; ASTM B167; ASTM B444; ASTM B622 etc

| Form | ASTM |

| Rod, bar and wire | B 164 |

| Plate, sheet and strip | B 127, B 906 |

| Seamless pipe and tube | B 165, B 829 |

| Welded pipe | B 725, B 775 |

| Welded tube | B 730, B 751 |

| Welding fitting | B 366 |

| Forging | B 564 |

Alloy 400 Chemical composition:

| % | Ni | Cu | Fe | C | Mn | Si | S |

| min | 63.0 | 28.0 | - | - | - | - | - |

| max | - | 34.0 | 2.5 | 0.30 | 2.00 | 0.50 | 0.024 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Welded Tube

1 Inch TP321 / 321H Stainless Steel Heat Exchanger U Bend Welded Tube For Chemical Industry

MTSCO heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products . Process : 1 . We use Cold Dra......

6.35mm ASTM A269 Stainless Steel Bright Annealed Welded Tubing in Transportation

Stainless steel seamless bright annealed tube's final surface is polished and bright annealed. And the polished grade is includes 180#, 320#, 400#, 600#, 800#. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. And they are very suitable for chro......

4.76mm TP316L / 1.4404 Stainless Steel Straight Heat Exchanger Welded Tube

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products . Application a) For fluid & gas ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語