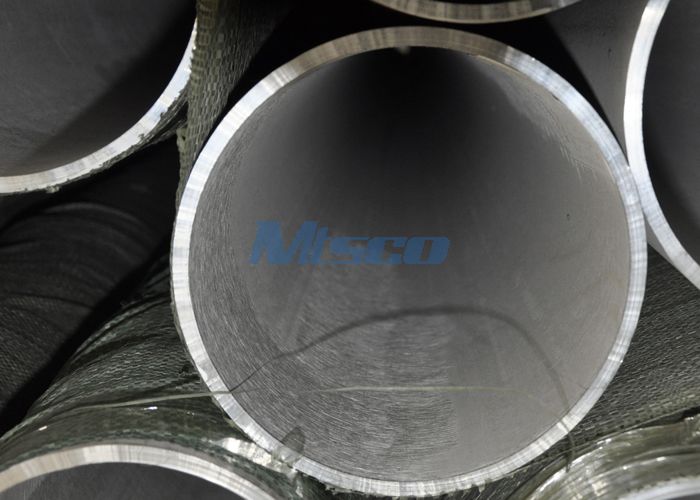

ASTM B619 / B626 Alloy 230 / UNS N06230 Nickel Alloy Welded Pipe

SSNAWP02

Material: Alloy 230, UNS N06230;

Get Quote

ASTM B619 / B626 Alloy 230 / UNS N06230 Nickel Alloy Welded Pipe

| Material Grade | Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030,Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 |

| Outer Diameter | 3.18mm-101.60mm |

| Wall Thickness | 0.50mm-20.00mm |

| Length | Normally fixed length 6m, can as per customer's requirement |

| Standard | ASTM B622, ASTM B163; ASTM B167; ASTM B444; etc |

1 . Our company has been dedicated to producing nickel alloy tube since 2003 , owning complete producing technology and abundant managing experience .

2 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

3 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloy's , SGS , etc , also can be provided according to customers' requirements .

4 . The surface condition is one of our main advantages : in order to meet different requirements for surface condition , we have annealing and pickling surface , bright annealing surface , polished surface etc .

5 . In order to keep the inside surface of pipe clean and make it free from deburring , our company develops the unique and special technology --- Sponge Washing with high pressure

6 . We have complete after-sale service to deal with the problems in time.

Alloy 230 Chemical composition:

| % | Ni | Cr | W | Mo | Co | Fe | C | Mn | Si | P | S | Al | La | B |

| min | balance | 20.0 | 13.0 | 1.0 | - | - | 0.05 | 0.30 | 0.25 | - | - | 0.20 | 0.005 | - |

| max | 24.0 | 15.0 | 3.0 | 5.0 | 3.0 | 0.15 | 1.00 | 0.75 | 0.030 | 0.015 | 0.50 | 0.050 | 0.015 |

Physical properties

| Density | 8.97 g/cm3 |

| Melting range | 1301-1371℃ |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Nickel Alloy Welded Pipe

ASTM B622 / B619 Alloy G-30 / UNS N06030 Nickel Alloy Pipe

1. Material Grade: Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030, Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 etc. 2. Outer Diameter: 10.3mm-406.4mm Wall Thickness: 1.24mm-40.49mm 3. Length: Normally fixed length......

ASTM B619 Alloy S / UNS N06635 Nickel Alloy Welded Pipe

1. Material Grade: Alloy S, Alloy C276/N10276, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc 2. Outer Diameter: 10.3mm-426mm Wall Thickness: 1.24mm-40.49mm 3. Length: Normally fixed length 6m, ca......

ASTM B619 / B626 Alloy 230 / UNS N06230 Nickel Alloy Welded Pipe

Material Grade :Alloy C-2000 / UNS N06200, Alloy G-35 / UNS N06035, Alloy G-30 / UNS N06030,Alloy G-30 / UNS N06030, Alloy S / UNS N06635, Alloy 230 / UNS N06230, Alloy 556 / UNS R30556 Outer Diameter: 3.18mm-101.60mm Wall Thickness: 0.50mm-20.00mm Length: Normally fixed length 6m, can as per c......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語