Common Flaw Detection Methods For Welded Pipes

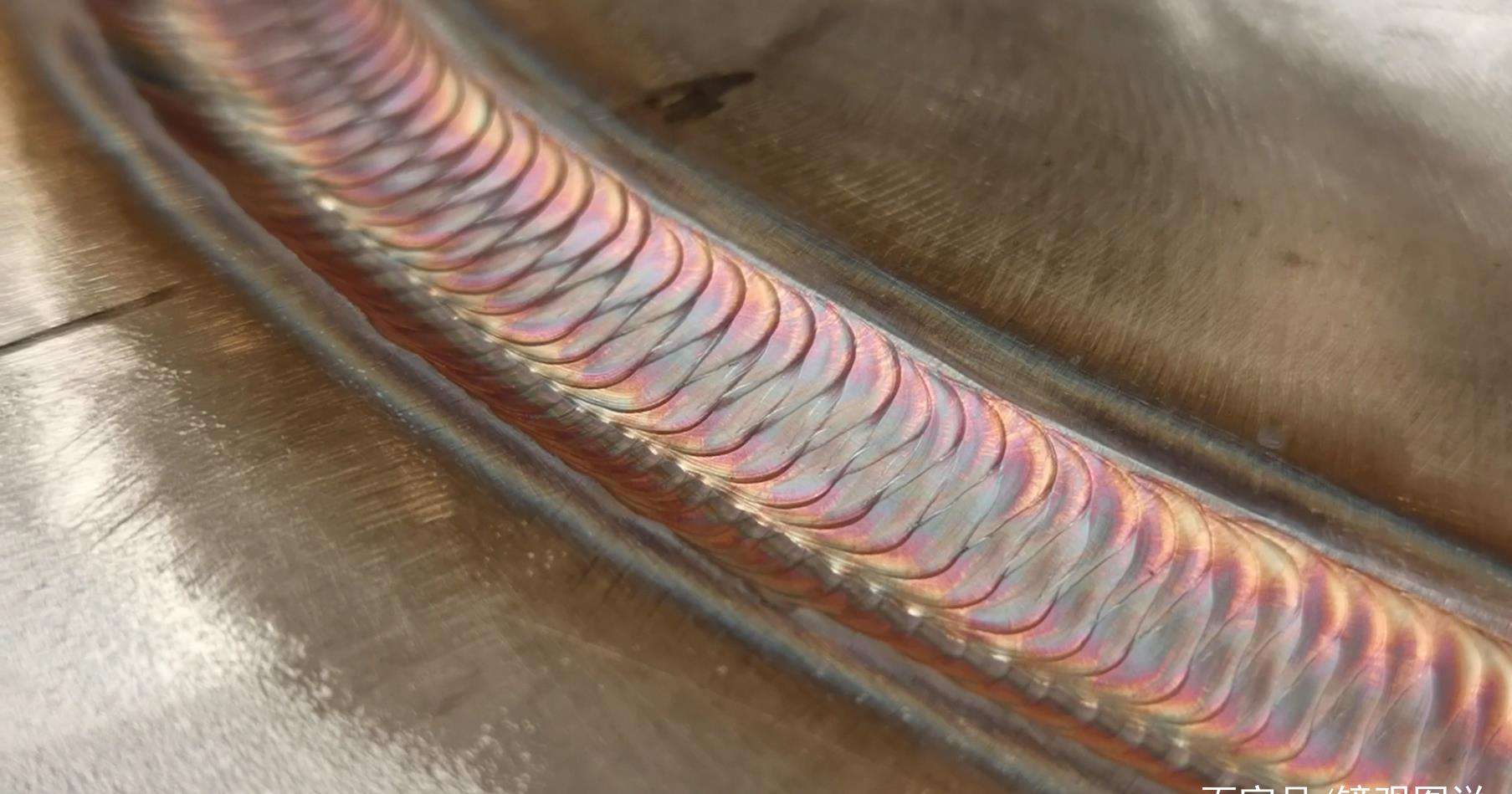

In the process of manufacturing and using welded pipe, nondestructive testing to ensure weld quality is particularly important.

The common nondestructive testing methods for welded pipes are: ultrasonic testing, off-line magnetic flux leakage testing and eddy current testing;

Ultrasonic flaw detection for the whole body of welded pipe

Ultrasonic flaw detection of welded pipe is mainly divided into direct contact method and liquid immersion method.

Direct contact method has the advantages of convenient operation, simple flaw detection graphics, easy judgment and high defect detection sensitivity. It is the most used method in actual flaw detection.

The method of immersing ultrasonic probe and workpiece in liquid and using liquid as coupling agent for flaw detection is called liquid immersion method. The coupling agent can be oil or water. This method is applicable to the specimen with rough surface. The probe is not easy to wear, the coupling is stable, and the detection results have good repeatability, which is convenient to realize automatic flaw detection.

Ultrasonic flaw detection of welded pipe welds

1) Off line flaw detection of welds

The welded pipe is sent to the flaw detection area from the transfer roller table, the rotating idler is raised, and the steel pipe weld is manually rotated to a certain point of the weld on the idler.

When the flaw detection trolley runs, each group of probes fall on the welded pipe in sequence. The coupling agent for flaw detection is the emulsion of the welded pipe production line, which receives the sensing signal and automatically sprays on the weld and both sides.

Because the ultrasonic off-line system is arranged after water cooling and air cooling, the influence of weld deviation becomes very important. Therefore, in the off-line flaw detection of weld, two groups of 6 probes in total are used for the detection of longitudinal linear defects of welded pipe weld, with 3 probes in each group, distributed on both sides of the weld, two-way detection, occupying 6 channels in total, and normal flaw detection can be carried out within 15mm of weld torsion (deviation).

2) Manual flaw detection of welds

The strict judgment of defects detected by off-line weld flaw detection needs to be confirmed by manual flaw detection.

Visual inspection shall be carried out on the weld and flaw detection surface before manual retest confirmation. The appearance quality shall meet the provisions of relevant standards. The shape of both sides of the weld and flaw detection surface shall not affect the detection of defects, otherwise grinding shall be carried out; The flaw detection inspector must check the testing equipment, whether the position and direction of the instrument are correct, and whether the coupling agent and testing joint are correct.

Before manual retest, the flaw detection equipment shall be verified. After the first verification, the second verification shall be carried out every 3 ~ 4H. At the end of the detection, the flaw detection equipment shall be verified again.

After the weld position is aligned, apply coupling agent (emulsion) on both sides of the weld for formal flaw detection; For the steel pipes that fail to pass the weld flaw detection, mark the defective parts and make detailed records.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語